At its core, vacuum induction melting (VIM) is the technology of choice for industries where material failure is not an option. The primary users are the aerospace, nuclear, medical, and high-end electronics sectors, which depend on VIM to create the ultra-pure, high-performance superalloys and specialty metals required for their most critical components.

The crucial insight is that a VIM furnace isn't just for melting metal; it's for refining it in a controlled environment. The vacuum is the key, as it removes atmospheric impurities and dissolved gases, enabling the creation of alloys with properties that are impossible to achieve with conventional melting techniques.

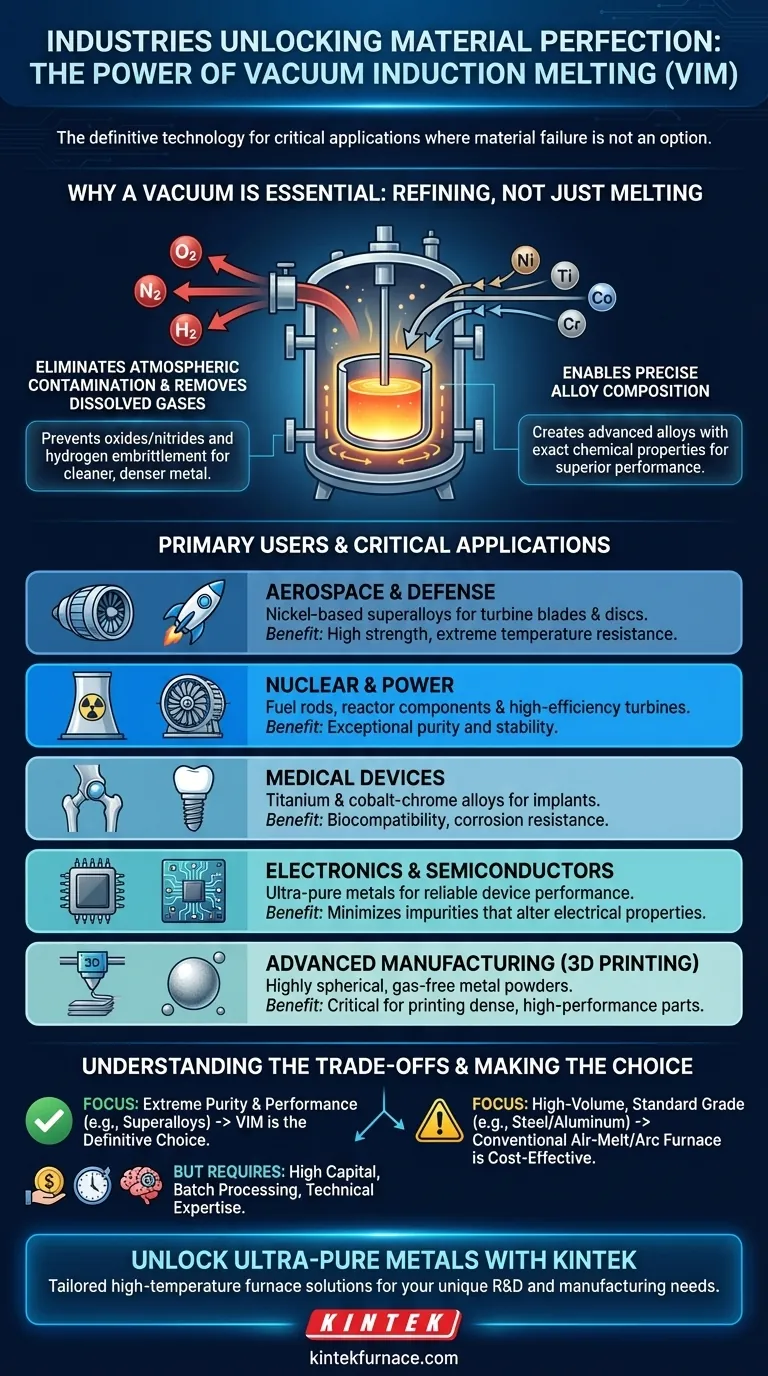

Why a Vacuum Environment is Essential

The defining feature of a VIM furnace is its ability to melt materials inside a vacuum chamber. This isn't an arbitrary detail—it is the central reason for its use in high-stakes manufacturing.

Eliminating Atmospheric Contamination

Standard atmosphere contains about 21% oxygen and 78% nitrogen. When melting reactive metals like titanium or superalloys, these gases readily combine with the molten metal, forming oxides and nitrides.

These impurities create microscopic defects that severely degrade the material's strength, ductility, and fatigue resistance, making it unsuitable for demanding applications.

Removing Dissolved Gases

Molten metals can hold dissolved gases, particularly hydrogen, which become trapped as the metal solidifies. This leads to hydrogen embrittlement, a condition that can cause catastrophic, brittle failure under stress.

The vacuum actively pulls these dissolved gases out of the molten bath, resulting in a cleaner, denser, and far more reliable final product.

Enabling Precise Alloy Composition

By starting with a clean, gas-free environment, metallurgists can introduce precise amounts of alloying elements. This allows for the creation of advanced alloys with exact chemical compositions, ensuring their performance characteristics meet stringent design specifications.

Core Industries and Their Demands

The need for absolute material integrity directly connects specific industries to VIM technology. Each sector leverages the furnace's capabilities to solve a unique set of engineering challenges.

Aerospace and Defense

This is the largest user of VIM technology. It's used to produce nickel-based superalloys for jet engine turbine blades, discs, and other components that must withstand extreme temperatures and mechanical stress.

The reliability provided by VIM is non-negotiable for manufacturing parts for aircraft, missiles, and rockets.

Nuclear and Power Generation

The nuclear industry requires materials with exceptional purity and stability for applications like fuel rods and reactor components. Power generation uses VIM-produced alloys for high-efficiency gas and steam turbines.

Medical Device Manufacturing

Medical implants, such as artificial hips, spinal fixtures, and dental posts, are often made from titanium or cobalt-chrome alloys.

VIM is essential for producing these materials with the extreme purity and biocompatibility needed to prevent rejection by the human body.

Electronics and Semiconductors

The manufacturing of semiconductors and advanced electronic components requires ultra-pure metals and alloys. Even minuscule impurities can alter electrical properties and cause device failure. VIM is used to refine these high-purity materials.

Advanced Manufacturing

A growing application is the production of highly spherical, gas-free metal powders for additive manufacturing (3D printing). The quality of VIM-produced powders is critical for printing dense, high-performance parts.

Understanding the Trade-offs

While powerful, VIM technology is not a universal solution. Its specialized nature comes with significant trade-offs that limit its use to specific applications.

High Capital and Operating Costs

VIM furnaces are complex systems involving sophisticated vacuum pumps, power supplies, and control systems. They are expensive to purchase, operate, and maintain compared to standard air-melt furnaces.

Batch Processing Limitations

The process of drawing a vacuum, melting, refining, and casting is inherently a batch operation. This makes VIM less efficient for the continuous, high-volume production of common-grade metals like standard steel or aluminum.

Technical Expertise Required

Operating a VIM furnace safely and effectively requires highly skilled metallurgists and technicians. The process is far more complex than simply melting metal in an open crucible.

Making the Right Choice for Your Goal

Selecting a melting technology depends entirely on the required quality of the final product and the economic constraints of the project.

- If your primary focus is extreme material purity and performance: VIM is the definitive choice for creating superalloys or specialty metals for critical applications where failure is unacceptable.

- If your primary focus is high-volume, standard-grade metal casting: A conventional air-melt induction furnace or an electric arc furnace is far more cost-effective and appropriate.

- If your primary focus is precious metal refining: VIM provides superior yield and purity for materials like gold and platinum, justifying its cost by minimizing loss and maximizing quality.

Ultimately, the use of a vacuum induction furnace is a deliberate choice driven by the uncompromising demand for material perfection.

Summary Table:

| Industry | Key Applications | Material Benefits |

|---|---|---|

| Aerospace & Defense | Jet engine turbine blades, discs | High strength, extreme temperature resistance |

| Nuclear & Power | Fuel rods, reactor components | Exceptional purity and stability |

| Medical | Implants (hips, spinal fixtures) | Biocompatibility, corrosion resistance |

| Electronics | Semiconductors, components | Ultra-pure metals for reliable performance |

| Advanced Manufacturing | Metal powders for 3D printing | Gas-free, spherical powders for dense parts |

Unlock the Power of Ultra-Pure Metals with KINTEK

Are you in the aerospace, nuclear, medical, electronics, or advanced manufacturing industries? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need to produce superalloys, refine specialty metals, or create high-purity materials, our VIM furnaces deliver unmatched performance and reliability.

Contact us today to discuss how our tailored solutions can enhance your material quality and efficiency—Get in touch now!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification