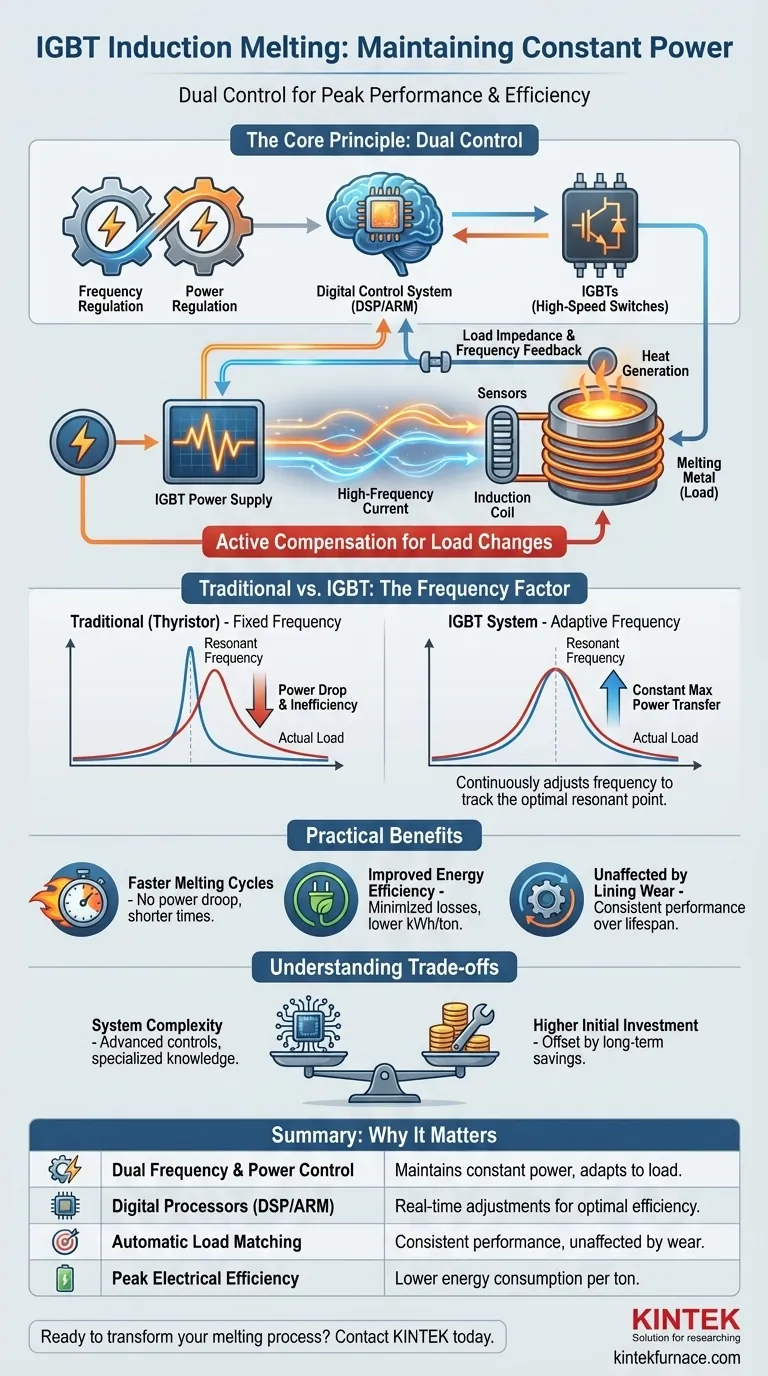

At its core, an IGBT induction melting furnace maintains constant power by using a sophisticated digital control system that simultaneously regulates both the output frequency and the power level. Unlike older thyristor-based systems that can only adjust power, this dual-control method actively compensates for changes in the furnace's electrical load, ensuring a consistent and highly efficient energy transfer throughout the entire melting process.

The critical advantage of an IGBT furnace is its ability to adapt. By continuously adjusting its operating frequency to match the changing electrical properties of the melting metal and the furnace lining, it ensures that the maximum requested power is always delivered to the charge.

The Core Principle: Dual Control of Frequency and Power

To understand why constant power is a significant technological achievement, we must first look at the limitations of older systems and how IGBT technology overcomes them.

Why Power Control Alone Isn't Enough

Traditional induction power supplies, often using thyristors (SCRs), primarily regulate the voltage or current to control power. However, the induction coil and the metal inside it (the load) form a resonant circuit.

The efficiency of power transfer is highest at a specific resonant frequency. As the metal heats, melts, and as the furnace lining wears down over time, the electrical characteristics (impedance) of this load change dramatically.

With a fixed or limited frequency range, a traditional power supply cannot adapt to these changes. The result is a mismatch between the power supply and the load, causing the actual power delivered to the metal to drop, even if the system is set to 100%.

The Role of Frequency Regulation

This is where the IGBT furnace's key innovation lies. The system doesn't just push more power; it intelligently finds the most efficient frequency to deliver that power.

By constantly adjusting the output frequency, the power supply can "track" the optimal resonant point of the furnace coil as the load conditions evolve. This process is often called frequency scanning or load matching.

This ensures the furnace is always operating at its peak electrical efficiency, allowing it to draw full power from the line and deliver it to the melt under all conditions.

How Digital Control Enables This

This dynamic dual control is made possible by two components working in tandem:

- IGBTs (Insulated-Gate Bipolar Transistors): These are extremely fast, high-power semiconductor switches. Their speed allows the system to generate a wide range of frequencies with high precision, something thyristors cannot do as effectively.

- Digital Processors (DSP/ARM): The entire operation is governed by an all-digital embedded software running on a processor. This "brain" constantly analyzes the furnace's electrical state and makes instantaneous adjustments to both frequency and power to maintain the target output.

The Practical Impact of Constant Power Output

Achieving constant power isn't just an electrical engineering feat; it delivers tangible benefits in a production environment.

Faster and More Consistent Melting Cycles

Because the furnace can maintain full power from a cold start through the entire melting phase, there is no "power droop" as the metal liquefies. This directly results in shorter, more predictable melting times and higher overall throughput.

Improved Energy Efficiency

By continuously operating at the optimal frequency, the system minimizes electrical losses. More of the energy drawn from the grid is converted into useful heat in the metal, leading to a lower kilowatt-hour consumption per ton of material melted.

Unaffected by Furnace Lining Wear

As the refractory lining erodes and becomes thinner over its lifespan, the electrical coupling between the coil and the metal changes. An IGBT system automatically compensates for this, delivering consistent melting performance from the first heat on a new lining to the last.

Understanding the Trade-offs

While highly effective, this technology comes with its own set of considerations.

System Complexity

IGBT power supplies are more technologically advanced than their thyristor predecessors. They rely on sophisticated digital control boards and advanced power electronics, which can require more specialized knowledge for diagnostics and repair.

Higher Initial Investment

The advanced components and control systems within an IGBT furnace typically result in a higher upfront capital cost compared to older, simpler technologies. However, this is often offset by lower operating costs and higher productivity over the equipment's lifespan.

Making the Right Choice for Your Operation

An IGBT furnace's constant power capability is a direct solution to the core challenges of induction melting: speed, efficiency, and consistency.

- If your primary focus is maximizing throughput: The ability to maintain full power throughout the melt guarantees the fastest and most predictable cycle times.

- If your primary focus is energy efficiency: The automatic load matching inherent in the dual-control system ensures minimal energy waste and lower electricity costs.

- If your primary focus is process consistency for high-value alloys: Constant power provides stable and repeatable melting conditions, which can reduce the loss of expensive alloying elements due to shorter heat times.

Ultimately, the ability to maintain constant power transforms the induction furnace from a static tool into an intelligent system that actively optimizes its own performance.

Summary Table:

| Feature | Benefit |

|---|---|

| Dual Frequency & Power Control | Actively compensates for load changes, maintaining constant power. |

| Digital Processors (DSP/ARM) | Enables real-time adjustments for optimal efficiency. |

| Automatic Load Matching | Faster melting cycles and consistent performance, unaffected by lining wear. |

| Peak Electrical Efficiency | Lower energy consumption per ton of material melted. |

Ready to transform your melting process with intelligent, high-efficiency technology?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse foundries and metal producers with advanced high-temperature furnace solutions. Our product line, including IGBT Induction Melting Furnaces, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique production requirements.

Contact KINTEK today to discuss how our constant-power IGBT furnace technology can deliver faster cycle times, lower energy costs, and unparalleled process consistency for your operation.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance