At its core, using Insulated Gate Bipolar Transistor (IGBT) technology in induction melting significantly reduces maintenance needs and operational downtime. The robust, solid-state nature of IGBT components means they are inherently more reliable and have fewer points of failure compared to older power supply systems, leading to increased furnace uptime and more consistent production.

The central benefit is simple: IGBTs are modern, solid-state switches with no moving parts. This fundamental design difference eliminates many of the common failure points found in traditional power supplies, directly translating to higher reliability, less required maintenance, and greater operational stability.

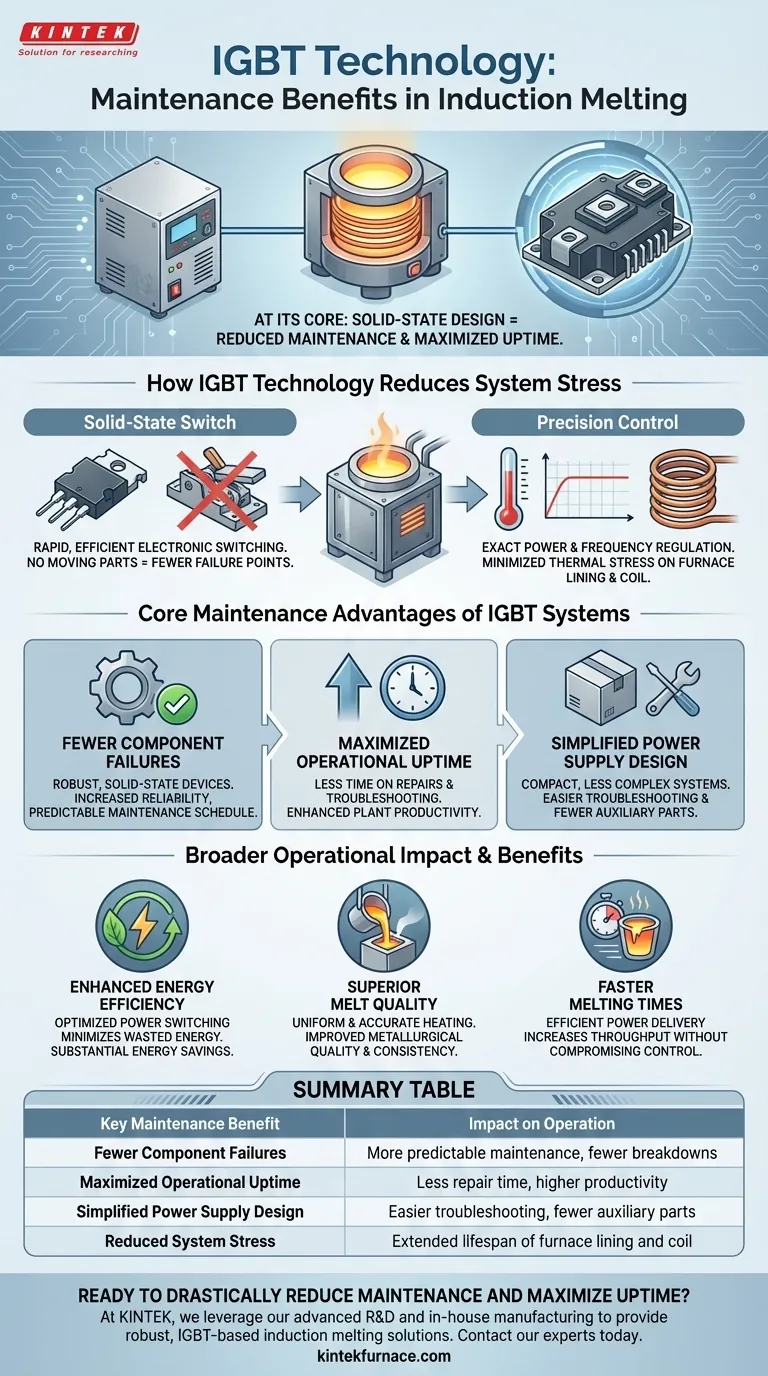

How IGBT Technology Reduces System Stress

To understand the maintenance benefits, we first need to understand what an IGBT is and how it functions within an induction furnace.

The Role of the IGBT as a Solid-State Switch

An IGBT is a powerful semiconductor that acts as an incredibly fast and efficient electronic switch. It combines the advantages of two other transistor types (BJT and MOSFET) to precisely control the flow of high-power electrical current to the induction coil.

This rapid switching is what generates the powerful magnetic field required for induction melting. Unlike older, more mechanical or less efficient systems, the IGBT provides this control with no physical moving parts.

Precision Control Minimizes Wear and Tear

Because IGBTs allow for exact regulation of power and frequency, they provide exceptionally precise temperature control. This prevents the system from overshooting temperature targets or creating unnecessary thermal stress on the furnace lining, induction coil, and other critical components.

This stable, controlled operation reduces cumulative wear and tear on the entire system, extending the life of its components and decreasing the frequency of maintenance interventions.

The Core Maintenance Advantages of IGBT Systems

The shift to IGBT power supplies brings direct and measurable maintenance benefits that impact the entire operation.

Fewer Component Failures

The primary advantage is a drastic reduction in component failures. IGBTs are robust, solid-state devices engineered for reliability in high-power applications. This inherent durability means fewer unexpected breakdowns and a more predictable maintenance schedule.

Maximized Operational Uptime

Fewer failures directly result in maximized operational uptime. With less time spent on repairs and troubleshooting, the furnace is available for production more often, minimizing costly disruptions and improving overall plant productivity.

Simplified Power Supply Design

IGBT-based power supplies are typically more compact and less complex than their predecessors. This streamlined design often means there are fewer sub-systems and auxiliary components that can fail, simplifying the troubleshooting process when maintenance is required.

Understanding the Broader Operational Impact

While the maintenance benefits are significant, they are part of a larger picture of improved performance and efficiency.

Enhanced Energy Efficiency

IGBTs excel at power switching, which minimizes the energy wasted as heat during operation. This superior efficiency optimizes energy consumption, leading to substantial and measurable energy savings over the life of the furnace.

Superior Melt Quality

The precise temperature control enabled by IGBTs ensures the material is heated uniformly and accurately. This consistency improves the metallurgical quality and integrity of the final product, helping operations meet even the most stringent quality standards.

Faster Melting Times

By delivering power to the coil more efficiently, IGBT systems can often achieve faster melting times. This increases throughput without compromising control, further boosting the productivity of the melting operation.

Making the Right Choice for Your Operation

Choosing the right power supply technology depends on balancing initial investment against long-term operational goals.

- If your primary focus is minimizing downtime and maintenance: The proven reliability and solid-state design of IGBT systems make them the superior choice for ensuring maximum furnace availability.

- If your primary focus is energy efficiency and reducing operational costs: The exceptional power-switching capabilities of IGBTs will deliver significant energy savings that compound over the equipment's lifespan.

- If your primary focus is process control and melt quality: The precise temperature regulation unique to IGBT technology is essential for producing consistent, high-quality melts that older systems cannot reliably match.

Ultimately, investing in IGBT technology is a strategic decision to enhance reliability, reduce long-term costs, and improve control over your entire melting process.

Summary Table:

| Key Maintenance Benefit | Impact on Operation |

|---|---|

| Fewer Component Failures | More predictable maintenance, fewer breakdowns |

| Maximized Operational Uptime | Less repair time, higher productivity |

| Simplified Power Supply Design | Easier troubleshooting, fewer auxiliary parts |

| Reduced System Stress | Extended lifespan of furnace lining and coil |

Ready to drastically reduce maintenance and maximize the uptime of your melting operation?

At KINTEK, we leverage our advanced R&D and in-house manufacturing to provide robust, IGBT-based induction melting solutions tailored for foundries and metal producers. Our systems are engineered for exceptional reliability and precise control, directly translating to less downtime and lower long-term costs.

Contact our experts today to discuss how our high-efficiency furnaces can enhance your productivity and reliability.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab