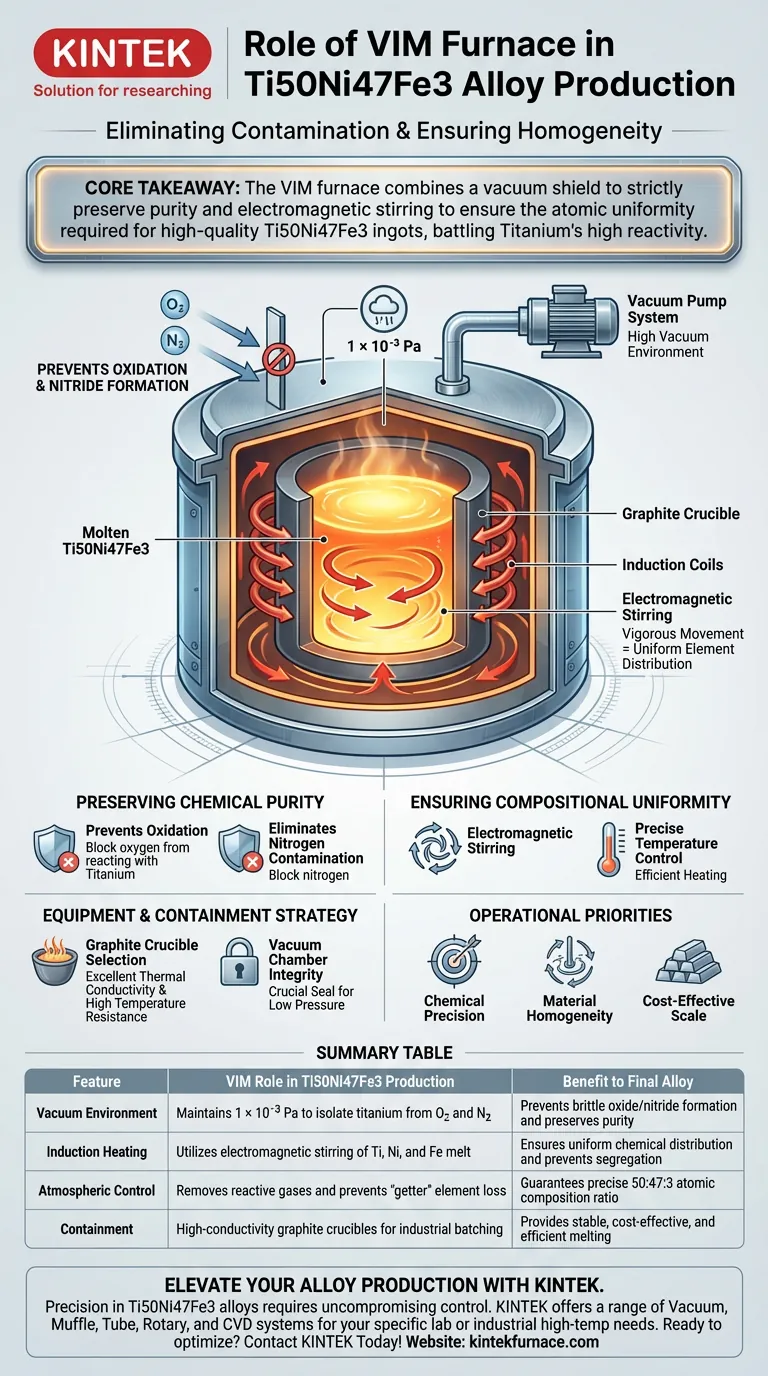

The primary role of a vacuum induction melting (VIM) furnace in producing Ti50Ni47Fe3 alloys is to eliminate atmospheric contamination while ensuring a homogeneous chemical structure. By maintaining a high-vacuum environment around $1 \times 10^{-3}$ Pa, the furnace prevents highly reactive elements like titanium from degrading, guaranteeing the alloy retains its precise composition and performance characteristics.

Core Takeaway The production of Ti50Ni47Fe3 is a battle against the high reactivity of titanium with oxygen and nitrogen. The VIM furnace wins this battle by combining a vacuum shield to strictly preserve purity with electromagnetic stirring to ensure the atomic uniformity required for high-quality industrial ingots.

Preserving Chemical Purity

The defining challenge in creating Ti50Ni47Fe3 is the sensitivity of its components. The VIM furnace addresses this by isolating the melt from the outside world.

Preventing Oxidation

Titanium (Ti) is a highly reactive metal ("getter") that avidly absorbs oxygen at high temperatures. If melted in air, titanium reacts to form brittle oxides, ruining the material.

The VIM furnace creates a vacuum ($1 \times 10^{-3}$ Pa) that removes air and other gases. This minimizes the risk of oxidation, ensuring the titanium remains metallic and active within the alloy matrix.

Eliminating Nitrogen Contamination

Like oxygen, nitrogen in the atmosphere can react with both titanium and nickel during the melting process. These reactions alter the chemical ratios of the final product.

By removing these gases, the furnace prevents the formation of nitrides. This guarantees that the final ingot maintains the exact Ti50Ni47Fe3 composition ratio, which is critical for the alloy's mechanical properties.

Ensuring Compositional Uniformity

Purity alone is not enough; the elements must be perfectly mixed. The VIM furnace utilizes the physics of induction to achieve this.

Electromagnetic Stirring

Induction heating does not just melt the metal; it agitates it. The electromagnetic field induces a stirring effect within the molten pool.

This vigorous movement forces the three distinct metals (Titanium, Nickel, and Iron) to mix thoroughly. This ensures a uniform distribution of elements, preventing segregation where one area might be iron-rich and another titanium-poor.

Precise Temperature Control

The absence of gases in the vacuum chamber alters how heat is transferred. With no gas to conduct heat away, heating efficiency improves significantly.

This allows for faster melting rates and more precise control over the temperature. Operators can maintain the melt exactly where needed to blend the Ti, Ni, and Fe without overheating or causing undue evaporation of volatile elements.

Equipment and Containment Strategy

The physical environment inside the furnace is just as critical as the vacuum itself.

Graphite Crucible Selection

For Ti50Ni47Fe3 alloys, a graphite crucible is typically selected as the containment vessel. This material is chosen for its excellent thermal conductivity and ability to withstand temperatures well above the alloy's melting point.

While titanium is reactive with many materials, graphite serves as an economical and effective container for large-scale industrial preparation of these specific alloys.

Vacuum Chamber Integrity

The vacuum chamber houses both the induction coil and the crucible. It is engineered to withstand extreme heat while maintaining the vacuum seal.

This integrity is vital; any leak that compromises the $1 \times 10^{-3}$ Pa pressure level would immediately introduce impurities, leading to the oxidative loss of active elements.

Understanding the Trade-offs

While VIM is the standard for high-performance alloys, it requires strict operational discipline to be effective.

The Sensitivity of Vacuum Levels

The process is entirely dependent on the quality of the vacuum. If the pressure rises above the target $1 \times 10^{-3}$ Pa, the protection against oxidation is compromised. Even trace amounts of remaining oxygen can degrade the mechanical performance of the final alloy.

Crucible Interactions

Graphite is chosen for its thermal properties and cost-effectiveness. However, in broader titanium metallurgy, carbon contamination is a known risk. For Ti50Ni47Fe3, graphite is deemed effective, but the interface between the reactive melt and the crucible must always be monitored to ensure the "economical" choice does not impact the alloy's required purity levels.

Making the Right Choice for Your Goal

To maximize the quality of your Ti50Ni47Fe3 production, focus on these operational priorities:

- If your primary focus is Chemical Precision: Strict adherence to the $1 \times 10^{-3}$ Pa vacuum level is non-negotiable to prevent the loss of reactive Titanium.

- If your primary focus is Material Homogeneity: Maximize the use of electromagnetic stirring to ensure Iron (Fe) is evenly dispersed throughout the Ti-Ni matrix.

- If your primary focus is Cost-Effective Scale: Utilize graphite crucibles to leverage their thermal conductivity and durability for high-volume industrial batching.

Ultimately, the VIM furnace is not just a heater; it is a precision instrument that locks in the chemistry required for advanced alloy performance.

Summary Table:

| Feature | VIM Role in Ti50Ni47Fe3 Production | Benefit to Final Alloy |

|---|---|---|

| Vacuum Environment | Maintains $1 \times 10^{-3}$ Pa to isolate titanium from $O_2$ and $N_2$ | Prevents brittle oxide/nitride formation and preserves purity |

| Induction Heating | Utilizes electromagnetic stirring of Ti, Ni, and Fe melt | Ensures uniform chemical distribution and prevents segregation |

| Atmospheric Control | Removes reactive gases and prevents "getter" element loss | Guarantees precise 50:47:3 atomic composition ratio |

| Containment | High-conductivity graphite crucibles for industrial batching | Provides stable, cost-effective, and efficient melting |

Elevate Your Alloy Production with KINTEK

Precision in Ti50Ni47Fe3 alloys requires the uncompromising control that only high-performance thermal systems can provide. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Vacuum, Muffle, Tube, Rotary, and CVD systems, all customizable to meet your specific lab or industrial high-temp needs.

Whether you are refining reactive titanium alloys or developing next-generation materials, our expert-engineered furnaces ensure the chemical purity and homogeneity your research demands.

Ready to optimize your thermal processes?

Contact KINTEK Today to Consult with Our Specialists

Visual Guide

References

- Shuwei Liu, Songxiao Hui. Effect of Annealing on the Microstructure, Texture, and Properties of Cold-Rolled Ti50Ni47Fe3 Shape Memory Alloy Sheets. DOI: 10.3390/cryst14040360

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace and Arc Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries