Virtually any industry requiring exceptionally pure and precisely controlled metals benefits from Vacuum Induction Melting (VIM) furnaces. The most prominent users are found in high-stakes sectors like aerospace, automotive, biomedical, and energy, where material failure is not an option. These furnaces are the gold standard for producing the advanced alloys and superalloys that power modern technology.

The true value of a Vacuum Induction Melting (VIM) furnace isn't just its ability to melt metal; it's the ability to do so in a controlled vacuum. This environment is the key to producing the ultra-pure, high-performance alloys that modern, high-stakes applications demand, free from the contamination inherent in atmospheric melting.

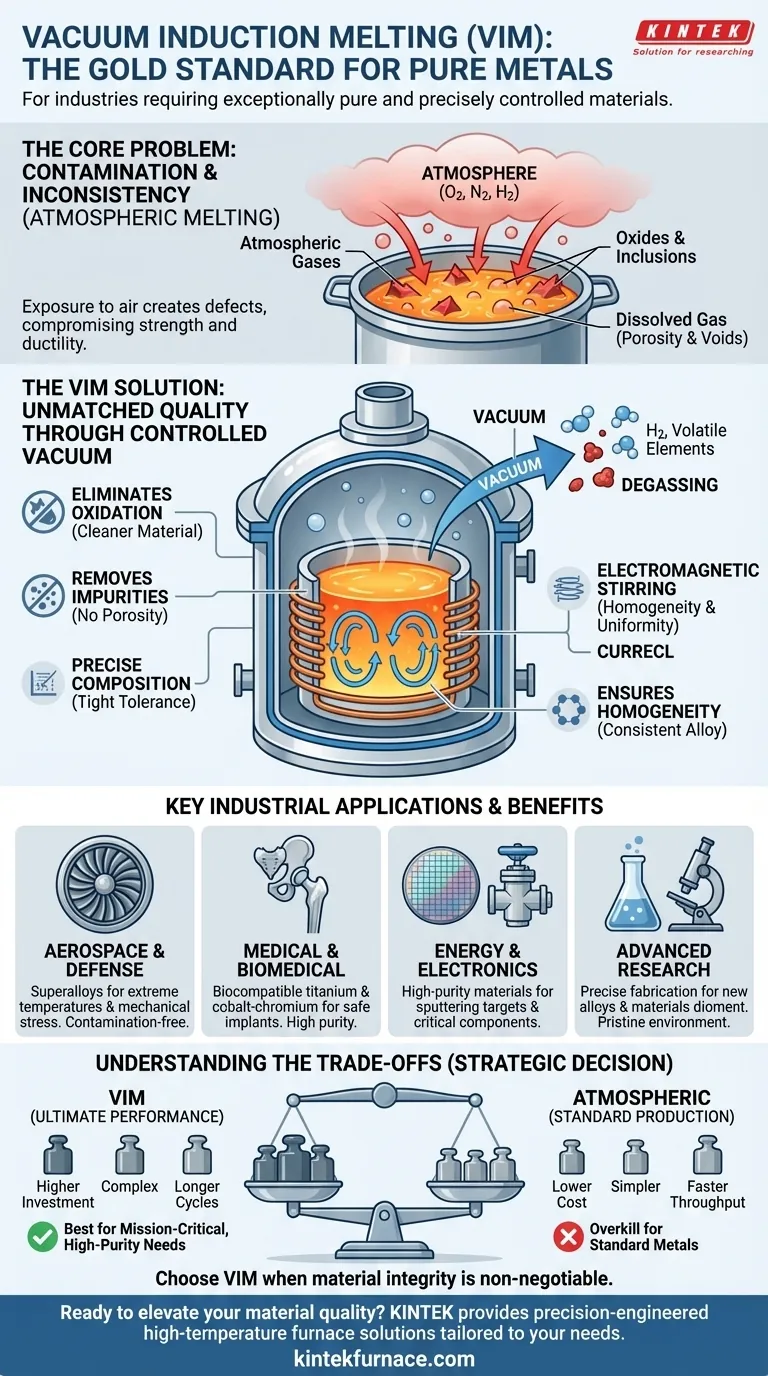

The Core Problem VIM Solves: Contamination and Inconsistency

To understand why VIM furnaces are so critical, you must first understand the fundamental challenges of traditional melting processes.

The Challenge of Atmospheric Melting

When metals are melted in the open air, they are exposed to oxygen, nitrogen, and other atmospheric gases. This exposure leads to the formation of unwanted oxides and other non-metallic inclusions.

These inclusions act as microscopic defects, compromising the metal's strength, ductility, and overall performance.

The Issue of Dissolved Impurities

Beyond surface-level oxidation, molten metals can also dissolve harmful gases like hydrogen.

As the metal cools and solidifies, this dissolved gas can come out of solution, creating internal porosity and voids that severely weaken the final component. Volatile trace elements can also remain, altering the material's properties.

How VIM Delivers Unmatched Material Quality

A VIM furnace directly counteracts these problems by fundamentally changing the melting environment. It provides a level of control that is impossible to achieve with other methods.

Eliminating Oxidation

By operating within a vacuum, the furnace removes the oxygen that would otherwise react with the molten metal. This prevents the formation of oxide inclusions, resulting in a cleaner, higher-quality material from the start.

Removing Gaseous and Volatile Elements

The vacuum environment actively pulls dissolved gases like hydrogen and other harmful volatile elements out of the molten bath. This process, known as degassing, eliminates the root cause of porosity and internal defects.

Achieving Precise Compositional Control

Alloying elements can be added with extreme precision inside the sealed vacuum chamber. This ensures the final chemical composition has very close compositional tolerance, meeting the demanding specifications for superalloys and other specialty metals.

Ensuring Homogeneity with Electromagnetic Stirring

VIM furnaces use induction currents not only to heat the metal but also to create an electromagnetic stirring effect. This gentle, continuous mixing prevents the segregation of different elements and ensures the final alloy is perfectly homogenous.

Key Industrial Applications

The superior material quality produced by VIM furnaces makes them indispensable in several key industries.

Aerospace and Defense

This is the quintessential VIM application. The process is used to create nickel-based superalloys for jet engine turbine blades, discs, and other components that must withstand extreme temperatures and mechanical stress.

Medical and Biomedical

Purity is paramount for medical implants like artificial hips and dental fixtures. VIM is used to produce highly pure titanium and cobalt-chromium alloys that are biocompatible and free from impurities that could cause an adverse reaction in the human body.

Energy and Electronics

The energy sector relies on VIM for producing complex valves and components for extreme service conditions. In electronics and semiconductors, the furnace produces the high-purity materials needed for sputtering targets and other critical components.

Advanced Research and Alloy Development

For materials scientists creating the next generation of materials, VIM provides a pristine environment. It allows for the precise fabrication of new high-temperature alloys, magnet materials, and special steels without the interference of outside contaminants.

Understanding the Trade-offs and Limitations

While VIM offers unparalleled quality, it is not the right choice for every application. Understanding its limitations is key to making an informed decision.

Higher Initial Investment and Complexity

VIM furnaces are sophisticated systems involving vacuum pumps, advanced power supplies, and complex control systems. This results in a significantly higher capital cost compared to standard atmospheric induction or arc furnaces.

Longer Cycle Times

The need to pump down the chamber to create a vacuum adds time to each melting cycle. For high-volume production of less critical metals, this slower throughput can be a major disadvantage.

Overkill for Standard Applications

For casting standard, non-reactive metals where ultimate purity is not the primary concern (e.g., many iron and steel castings), a VIM furnace is unnecessary. The added cost and complexity provide no significant benefit for these materials.

Making the Right Choice for Your Goal

The decision to use a VIM furnace should be driven entirely by your material performance requirements.

- If your primary focus is ultimate material purity and performance: VIM is non-negotiable for creating mission-critical superalloys, medical-grade metals, and high-purity electronic materials.

- If your primary focus is compositional precision and developing new alloys: The controlled and clean environment of a VIM is essential for research and development where repeatable, predictable results are critical.

- If your primary focus is high-volume production of standard metals: A VIM is likely overly complex and costly; simpler and faster atmospheric melting processes are more suitable.

Ultimately, selecting a VIM furnace is a strategic decision to prioritize material integrity and performance above all else.

Summary Table:

| Industry | Key Benefits |

|---|---|

| Aerospace & Defense | Produces superalloys for extreme temperature and stress resistance, free from contamination. |

| Medical & Biomedical | Ensures biocompatible, pure titanium and cobalt-chromium alloys for safe implants. |

| Energy & Electronics | Provides high-purity materials for critical components in valves, semiconductors, and sputtering targets. |

| Advanced Research | Enables precise alloy development in a contaminant-free environment for innovation. |

Ready to elevate your material quality with precision-engineered furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces tailored to your needs. Our product line—including Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, and more—is backed by deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, medical, or research, we deliver reliable, high-performance solutions. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control