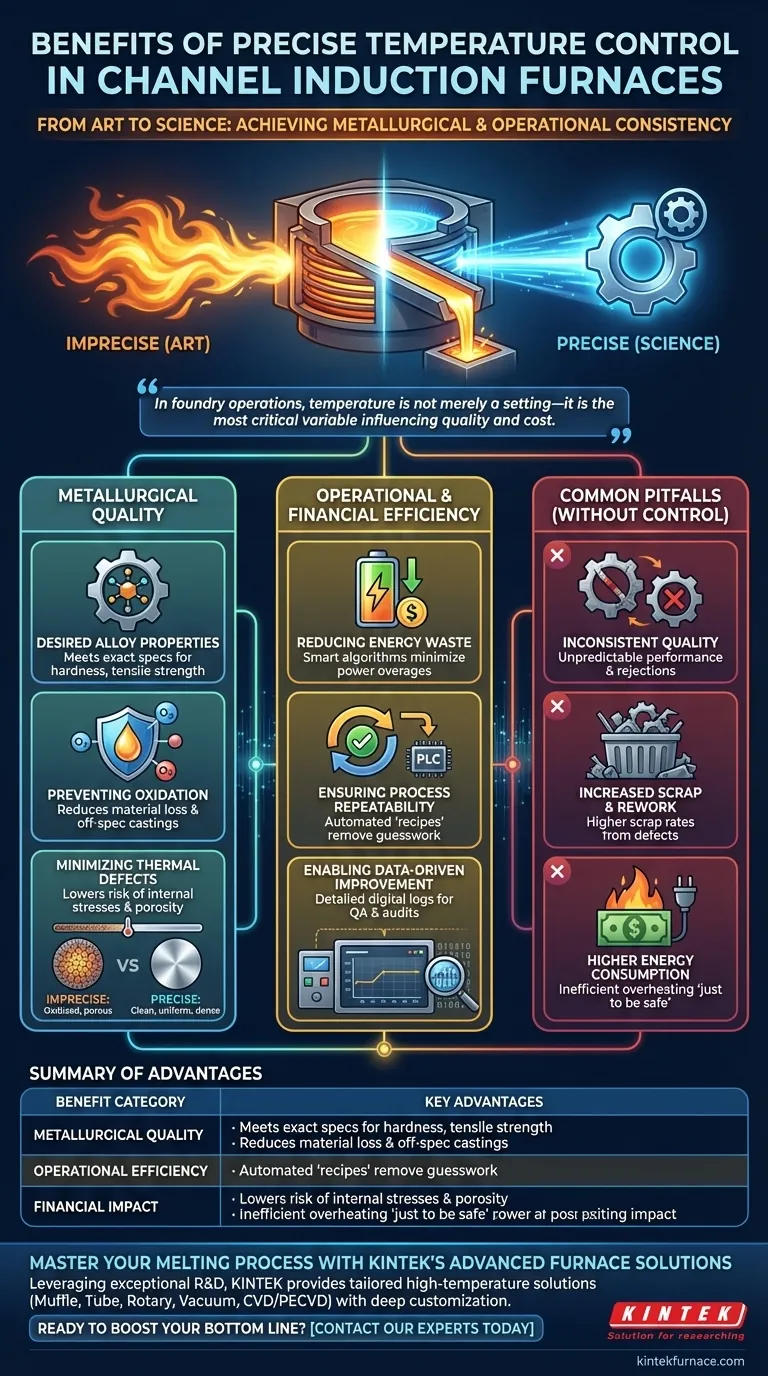

Ultimately, the primary benefit of precise temperature control in a channel induction furnace is metallurgical and operational consistency. It allows you to reliably achieve desired metal properties, minimize material and energy waste, and drastically improve the quality and repeatability of your final product. This shifts the melting process from an art based on operator experience to a science based on exact parameters.

In foundry operations, temperature is not merely a setting—it is the most critical variable influencing quality and cost. Precise control transforms the furnace from a simple melting device into an engineering tool that directly reduces defects, lowers energy consumption, and guarantees repeatable results.

The Impact on Metallurgical Quality

The most profound benefits of precise temperature control are seen in the metal itself. The final characteristics of a cast part are determined by its thermal history, which begins in the furnace.

Achieving Desired Alloy Properties

Every alloy has an ideal casting temperature window. Even minor deviations can alter the final microstructure, impacting mechanical properties like hardness, tensile strength, and ductility. Precise control ensures the metal is poured at the exact temperature required to meet engineering specifications.

Preventing Oxidation and Decarburization

Overheating the molten bath is a common and costly mistake. It accelerates the rate of oxidation, burning off valuable and expensive alloying elements. This not only wastes material but also changes the chemical composition of the final product, leading to off-spec castings.

Minimizing Thermal Defects

Precise control systems maintain a very small temperature difference between the core of the molten metal and its surface. This thermal uniformity reduces the risk of internal stresses, gas porosity, and other defects that can form during solidification.

Driving Operational and Financial Efficiency

Beyond quality, precise control is a powerful lever for improving your bottom line. It targets the two largest cost centers in a foundry: energy and scrap.

Reducing Energy Waste

An induction furnace that constantly overshoots its target temperature is wasting significant amounts of electricity. Modern control systems use sophisticated algorithms to apply power intelligently, reaching the setpoint quickly and holding it there with minimal energy input, preventing costly overages.

Ensuring Process Repeatability

Systems integrated with a PLC (Programmable Logic Controller) allow you to automate the entire heating process. You can program and save specific "recipes" for different alloys, removing operator guesswork and ensuring every batch is produced under identical conditions.

Enabling Data-Driven Improvement

Automated control systems create a detailed digital record of every melt cycle. This data is invaluable for quality assurance, process analysis, and troubleshooting. It provides a clear, objective log for internal audits or to demonstrate compliance with customer requirements.

Common Pitfalls Without Precise Control

Operating without precise, automated temperature control exposes a facility to significant and unnecessary risks. These issues often compound, eroding profitability and reputation.

Inconsistent Product Quality

Relying on manual control or outdated systems inevitably leads to batch-to-batch variation. This inconsistency results in unpredictable product performance and a higher likelihood of customer rejections.

Increased Scrap and Rework

Pouring metal that is too hot or too cold is a primary cause of casting defects. This leads directly to increased scrap rates, forcing costly remelts or time-consuming rework.

Higher Energy Consumption

Without a system that prevents it, operators often default to overheating the metal "just to be safe." This practice serves as an expensive and inefficient buffer, leading to consistently higher energy bills.

How to Apply This to Your Operation

When evaluating furnace technology or process upgrades, your decision should be guided by your specific operational goals.

- If your primary focus is producing high-specification alloys: Prioritize a control system that guarantees minimal temperature variance to ensure you consistently hit precise metallurgical targets.

- If your primary focus is reducing operational costs: Look for systems that combine precise control with advanced power management to minimize energy consumption and scrap rates.

- If your primary focus is process consistency and traceability: Invest in PLC-based controls that offer robust recipe management and detailed data logging for unparalleled quality assurance.

By mastering temperature, you gain control over the quality, efficiency, and profitability of your entire casting process.

Summary Table:

| Benefit Category | Key Advantages |

|---|---|

| Metallurgical Quality | Achieves desired alloy properties, prevents oxidation, minimizes thermal defects |

| Operational Efficiency | Reduces energy waste, ensures process repeatability, enables data-driven improvement |

| Financial Impact | Lowers scrap and rework costs, decreases energy consumption, improves profitability |

Master Your Melting Process with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides foundries and metal producers with advanced high-temperature furnace solutions tailored for precise thermal control. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique operational requirements.

Ready to achieve metallurgical consistency, reduce waste, and boost your bottom line? Contact our experts today to discuss how our customized furnace solutions can transform your casting process from an art into a science.

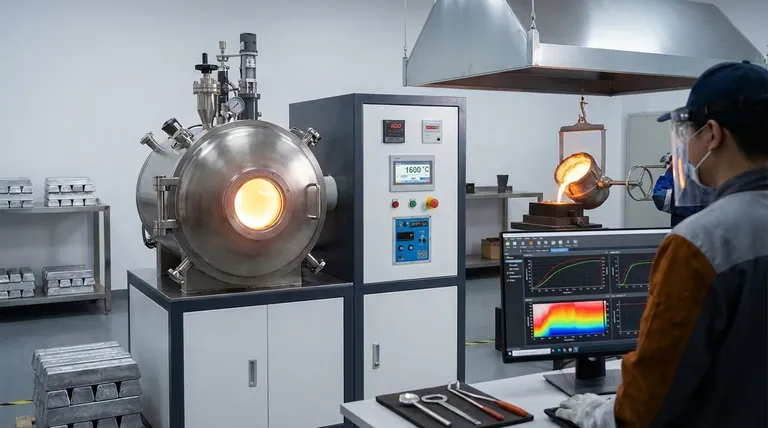

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys