At their core, IGBT induction melting furnaces achieve superior precision through exceptionally fast and accurate control over the energy delivered to the metal. This is made possible by the use of Insulated Gate Bipolar Transistors (IGBTs), which act as high-speed electronic switches. This technology allows for pinpoint management of temperature, rapid heating cycles, and inherent electromagnetic stirring, resulting in a homogenous and pure final material.

The defining advantage of an IGBT furnace is its ability to translate high-frequency electrical power into precise metallurgical outcomes. It gives operators direct, instantaneous control over the two most critical variables in quality metal production: temperature and composition.

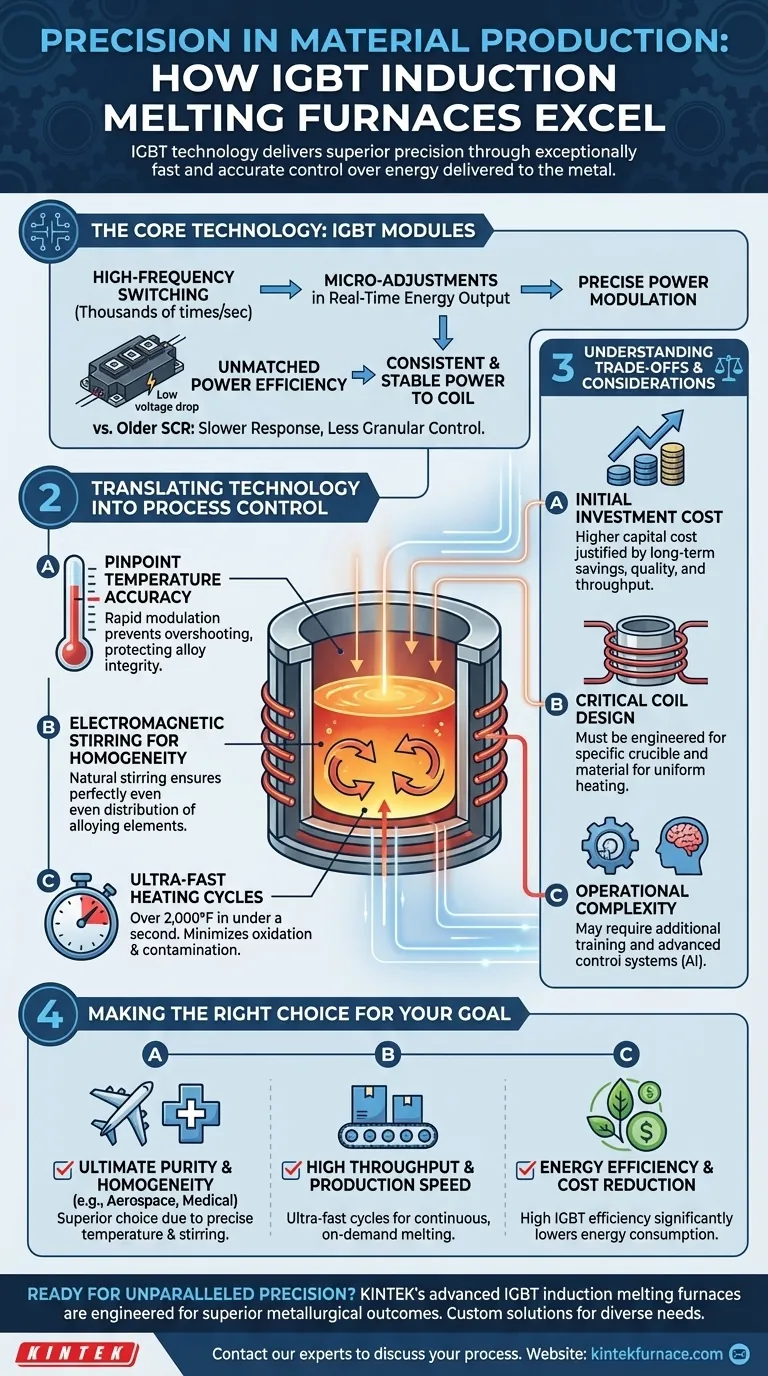

The Core Technology: What Makes IGBTs a Game Changer?

The precision of these furnaces begins with the IGBT module itself. Understanding this component is key to understanding its impact on the final product.

High-Frequency Switching for Rapid Response

An IGBT is a semiconductor device capable of switching power on and off thousands of times per second. This high switching frequency allows the furnace's power supply to make micro-adjustments to the energy output in real time.

This contrasts sharply with older technologies like SCR (Silicon-Controlled Rectifier) systems, which have slower response times and less granular control.

Precise Power Modulation

Because the IGBT can be controlled so finely, the furnace can deliver the exact amount of power needed to reach and hold a target temperature without overshooting. This prevents the degradation of alloys and reduces the introduction of impurities that can occur at excessive temperatures.

Unmatched Power Efficiency

IGBTs have a very low on-state voltage drop, meaning they waste very little energy as heat during operation. This efficiency ensures that the power sent to the induction coil is consistent and stable, eliminating fluctuations that could compromise the melt's quality.

Translating Technology into Process Control

This advanced electronic control directly translates into superior management of the melting process itself, impacting everything from material consistency to production speed.

Pinpoint Temperature Accuracy

The ability to rapidly modulate power allows the system to maintain the molten bath temperature with extreme precision. This is critical for producing alloys with specific phase structures and mechanical properties, as even small temperature deviations can alter the final result.

Electromagnetic Stirring for Homogeneity

The alternating magnetic field generated by the induction coil does more than just heat the metal; it also creates a natural, vigorous stirring action within the molten bath.

This electromagnetic stirring is essential for precision. It ensures that alloying elements are distributed perfectly evenly, eliminating inconsistencies and producing a chemically homogenous final product.

Ultra-Fast Heating Cycles

IGBT induction furnaces can heat materials to over 2,000°F in under a second. This speed minimizes the time the material is held at high temperatures, significantly reducing the opportunity for oxidation or contamination from the atmosphere.

Rapid heating and cooling also enable a continuous workflow, eliminating the delays associated with batch processing.

Understanding the Trade-offs and Considerations

While powerful, IGBT technology is not a universal solution. A clear understanding of its context is necessary for a successful implementation.

Initial Investment Cost

These furnaces represent a significant technological advancement over older systems, and their initial capital cost is higher. This investment is typically justified by reduced energy consumption, higher product quality, and increased throughput over the long term.

Coil Design is Critical

The efficiency and effectiveness of an induction furnace are heavily dependent on the design of the induction coil. The coil must be specifically engineered for the crucible size, shape, and the type of material being melted to ensure uniform heating.

Operational Complexity

To leverage the full precision of an IGBT furnace, operators may require additional training. Furthermore, optimizing processes for energy use and predictive maintenance often involves integrating advanced control systems, sometimes incorporating AI to analyze operational data.

Making the Right Choice for Your Goal

The decision to use an IGBT induction furnace should be driven by your specific production requirements.

- If your primary focus is ultimate material purity and homogeneity (e.g., aerospace, medical alloys): The combination of precise temperature control and electromagnetic stirring makes this technology the superior choice.

- If your primary focus is high throughput and production speed: The ultra-fast heating and cooling cycles minimize process time and allow for continuous, on-demand melting directly on the production floor.

- If your primary focus is energy efficiency and reducing operational costs: The high efficiency of IGBT power supplies significantly lowers energy consumption per ton of metal melted compared to older technologies.

Ultimately, adopting an IGBT induction furnace is an investment in control, giving you the power to dictate the exact properties of your material with unparalleled precision.

Summary Table:

| Feature | Impact on Precision |

|---|---|

| High-Frequency IGBT Switching | Enables real-time, micro-adjustments to power for exact temperature control. |

| Precise Power Modulation | Prevents temperature overshooting, protecting alloy integrity and reducing impurities. |

| Electromagnetic Stirring | Ensures perfect chemical homogeneity by evenly distributing alloying elements. |

| Ultra-Fast Heating Cycles | Minimizes oxidation and contamination for higher material purity. |

Ready to achieve unparalleled precision and purity in your metal production?

KINTEK's advanced IGBT induction melting furnaces are engineered to deliver the exact control you need for superior metallurgical outcomes. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with robust solutions featuring precise temperature management, inherent electromagnetic stirring, and rapid heating cycles.

Our deep customization capabilities ensure your furnace is perfectly tailored to your unique material and production requirements. Whether your focus is on aerospace alloys, medical components, or high-throughput manufacturing, KINTEK empowers you with the technology to dictate the exact properties of your final product.

Contact our experts today to discuss how a custom KINTEK IGBT furnace can transform your material production process.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency