In the field of modern metallurgy, medium frequency induction furnaces serve a highly specialized and critical role. They are used to execute precise heat treatment processes—such as annealing, quenching, and tempering—by generating heat directly within the metal itself through electromagnetic induction. This method allows for exceptional control over heating and cooling rates, enabling engineers to achieve specific, desired metallurgical properties like hardness, strength, and ductility in finished components.

The core value of a medium frequency induction furnace lies in its ability to deliver rapid, localized, and highly repeatable heating. This precision is what separates it from conventional furnaces, making it the superior choice for high-performance applications where material properties are non-negotiable.

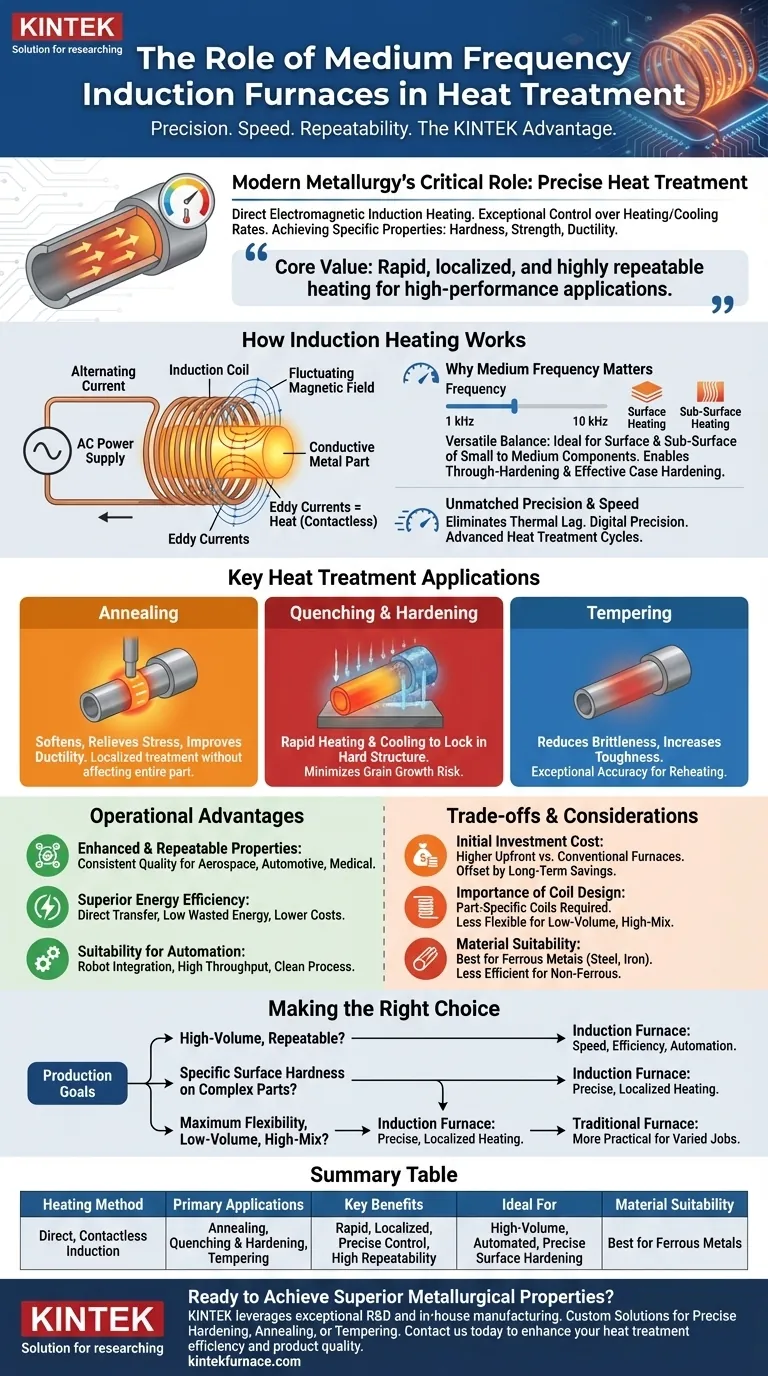

The Core Principle: How Induction Heating Works

To understand the furnace's role, you must first understand its mechanism. Unlike a traditional oven that heats the air around a part, an induction furnace uses a fundamentally different and more direct method.

The Role of Electromagnetic Induction

An alternating current is passed through a copper coil, creating a fluctuating magnetic field. When a conductive metal part is placed inside this coil, the magnetic field induces electrical currents (known as eddy currents) directly within the part.

The material's natural resistance to the flow of these eddy currents generates precise and rapid heat. It is a contactless process where the part becomes its own heating element.

Why "Medium Frequency" Matters

The frequency of the alternating current is a critical parameter that determines the depth of heat penetration.

Medium frequencies (typically 1 kHz to 10 kHz) provide a versatile balance, making them ideal for heating the surface and sub-surface of small to medium-sized components. This allows for both through-hardening of smaller parts and effective case hardening (surface hardening) of larger ones.

Unmatched Precision and Speed

Because heating occurs directly within the metal, the process is incredibly fast and efficient. Temperatures can be raised and controlled with digital precision, eliminating the thermal lag associated with conventional furnaces. This speed and control are essential for advanced heat treatment cycles.

Key Heat Treatment Applications

The unique capabilities of induction heating make it ideal for several standard metallurgical processes where control is paramount.

Annealing

Annealing is a process that softens metal, relieves internal stresses, and improves its ductility and toughness. Induction allows for very localized annealing, treating only the specific area of a component that needs to be softened without affecting the rest of the part.

Quenching and Hardening

This process involves heating a metal to a specific temperature and then cooling it rapidly (quenching) to lock in a harder, stronger crystalline structure. The rapid heating capability of an induction furnace minimizes the time the part spends at high temperatures, reducing the risk of grain growth or surface decarburization.

Tempering

After hardening, a metal is often too brittle for practical use. Tempering involves reheating it to a lower, precisely controlled temperature to reduce some of that brittleness and increase toughness. The exceptional temperature accuracy of induction systems makes them perfect for hitting the exact tempering point required.

Understanding the Operational Advantages

The adoption of medium frequency induction furnaces is driven by clear benefits in both material quality and production efficiency.

Enhanced and Repeatable Properties

The primary advantage is achieving superior metallurgical outcomes. The precise control over the heating cycle ensures that every part is treated identically, leading to consistent quality and performance, which is vital in aerospace, automotive, and medical industries.

Superior Energy Efficiency

Since energy is transferred directly to the workpiece, very little is wasted heating the furnace walls or the surrounding atmosphere. This results in significantly lower energy consumption compared to radiant or convection furnaces, reducing operational costs.

Suitability for Automation

The speed, precision, and clean nature of induction heating make it easy to integrate into automated production lines. Parts can be moved in and out of the coil by robots, ensuring high throughput and minimizing manual labor.

Acknowledging the Trade-offs and Considerations

While powerful, induction technology is not a universal solution. An objective assessment requires understanding its limitations.

Initial Investment Cost

The upfront cost for an induction heating system, including the power supply and coils, is typically higher than that of a conventional fuel-fired or resistance furnace. However, this is often offset by lower long-term operational costs.

The Importance of Coil Design

The induction coil must be carefully designed and shaped to match the geometry of the workpiece for efficient heating. This means a new coil may be required for each new part design, making it less flexible for low-volume, high-mix production runs.

Material Suitability

Induction heating works best with electrically conductive materials, particularly ferrous metals like steel and iron. While it can be adapted for non-ferrous metals like aluminum or copper, it is generally less efficient and may require different frequencies and power levels.

Making the Right Choice for Your Process

Selecting the correct heating technology depends entirely on your specific production and material goals.

- If your primary focus is high-volume, repeatable production: An induction furnace is the ideal choice due to its speed, energy efficiency, and ease of automation.

- If your primary focus is achieving specific surface hardness on complex parts: The precise, localized heating of induction is unmatched for processes like case hardening without distorting the entire component.

- If your primary focus is maximum flexibility for varied, low-volume jobs: A traditional resistance or gas batch furnace may be more practical and cost-effective, as it does not require part-specific coils.

Ultimately, understanding these core principles empowers you to align the right technology with your specific engineering requirements and manufacturing goals.

Summary Table:

| Aspect | Key Advantage |

|---|---|

| Heating Method | Direct, contactless heating via electromagnetic induction |

| Primary Applications | Annealing, Quenching & Hardening, Tempering |

| Key Benefits | Rapid & localized heating, Exceptional control, High repeatability |

| Ideal For | High-volume production, Automated lines, Precise surface hardening |

| Material Suitability | Best for ferrous metals (steel, iron); adaptable for non-ferrous |

Ready to achieve superior metallurgical properties with precision heating?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our expertise in medium frequency induction technology, combined with strong deep customization capabilities, allows us to deliver systems tailored to your unique experimental and production requirements—whether you need precise hardening, annealing, or tempering processes.

Contact us today to discuss how our solutions can enhance your heat treatment efficiency and product quality.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Induction Melting Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability

- What are the main applications of vacuum hot pressing? Create Dense, Pure Materials for Demanding Industries

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision