In essence, induction furnaces are uniquely suited for precious metals because they offer unparalleled control over the three factors that matter most: purity, temperature, and efficiency. This technology uses electromagnetic fields to heat the metal directly and internally, which prevents contamination from external fuel sources, allows for surgical temperature precision, and minimizes the energy waste common in traditional furnaces.

The core challenge in processing precious metals is preserving their immense value by preventing contamination and material loss. Induction technology solves this by offering a clean, contained, and highly efficient heating method that works from the inside out, ensuring maximum purity and yield.

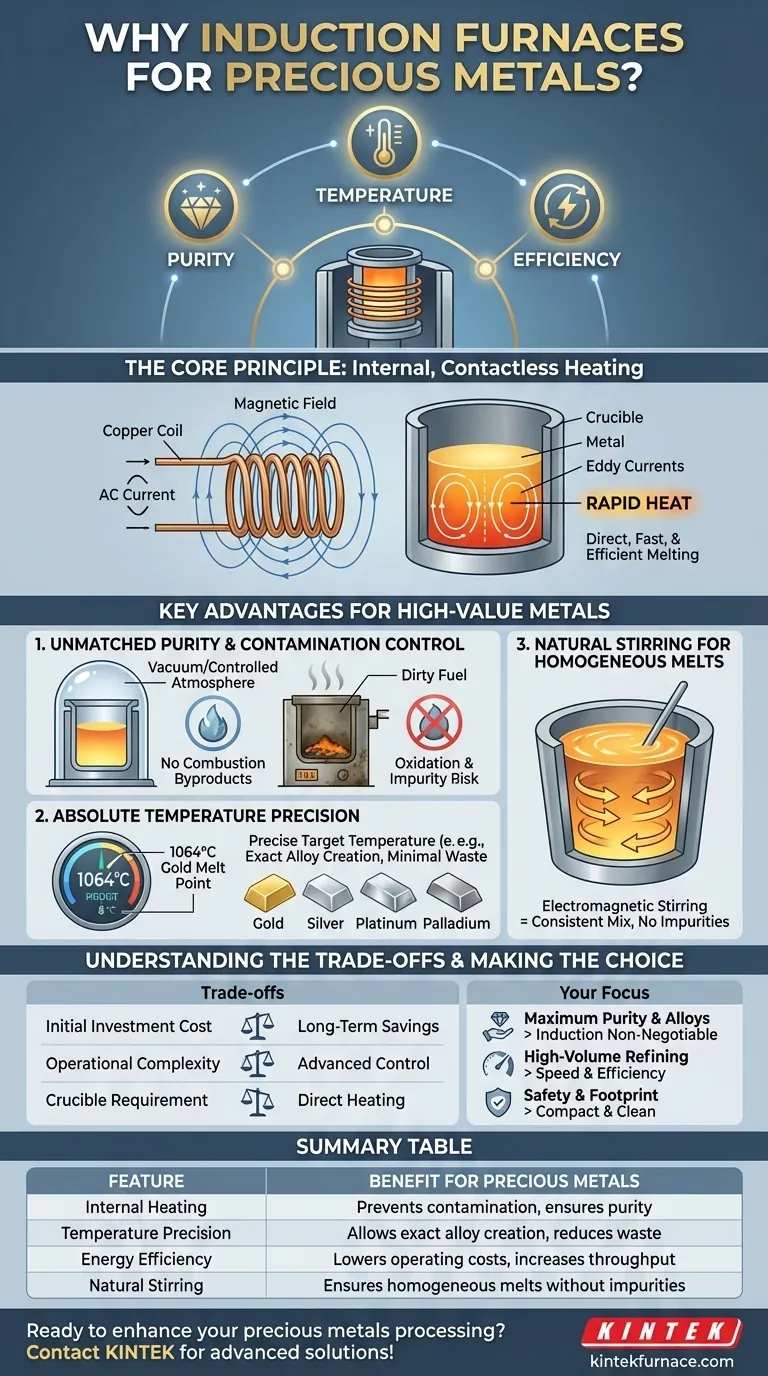

The Core Principle: Internal, Contactless Heating

The genius of induction lies in how it generates heat. Unlike a traditional furnace that heats a chamber with fire or resistance elements, an induction furnace heats the metal itself without direct contact.

How Electromagnetic Induction Works

An induction system consists of a crucible (a container for the metal) surrounded by a copper coil. When a powerful alternating current flows through this coil, it creates a rapidly changing magnetic field.

This magnetic field penetrates the conductive metal inside the crucible, inducing powerful electrical currents within it, known as eddy currents. The metal's natural resistance to these currents generates immense, rapid heat—a process called resistive heating.

The Direct Benefit: Speed and Efficiency

Because the heat is generated directly within the metal, the melting process is incredibly fast and efficient. There is no wasted energy heating the furnace walls or the surrounding air first. This translates directly to lower energy costs and higher throughput.

Why This Matters for High-Value Metals

The unique properties of induction heating directly solve the primary challenges of working with materials like gold, silver, and platinum group metals.

Unmatched Purity and Contamination Control

Traditional fuel-fired furnaces introduce byproducts of combustion directly into the melt, risking contamination. Induction heating is completely clean as it relies only on electricity.

Furthermore, the process can occur in a controlled environment with low oxygen or even in a vacuum, which prevents oxidation—a major cause of material loss and impurity. The use of specialized, non-reactive crucibles made of materials like graphite or ceramic ensures the container itself does not contaminate the melt.

Absolute Temperature Precision

Creating specific alloys, such as 14k or 18k gold, requires exact temperatures to ensure the correct properties and color. Overheating can vaporize valuable metal, leading to direct financial loss.

Induction systems provide exceptionally precise temperature control, allowing operators to hit and hold specific target temperatures with minimal deviation. This precision is fundamental to consistent quality and minimizing waste.

Natural Stirring for Homogeneous Melts

A secondary effect of the strong magnetic fields is a natural stirring or agitation within the molten metal. This electromagnetic stirring ensures that alloys are mixed thoroughly and become perfectly homogeneous without the need for mechanical stirrers that could introduce impurities.

Understanding the Trade-offs

While highly advantageous, induction technology is not without its considerations. An objective analysis requires acknowledging its limitations.

Initial Investment Cost

The upfront capital cost for an induction furnace system is typically higher than for a simple gas or resistance furnace. However, this is often offset over time by lower operating costs, higher efficiency, and reduced material loss.

Requirement for Conductive Crucibles

In some configurations, particularly for non-conductive materials, a conductive crucible (like graphite) is needed to heat up first and then transfer that heat to the material inside. For precious metals, which are themselves conductive, this is less of an issue as the metal heats directly.

Operational Complexity

Modern induction furnaces are highly automated, but they are more complex machines than a simple torch. Proper operation and maintenance require a degree of technical understanding to ensure safety and longevity.

Making the Right Choice for Your Application

Your final decision should be guided by your specific operational priorities.

- If your primary focus is maximum purity and creating complex alloys: The unparalleled contamination control and temperature precision of induction heating are non-negotiable.

- If your primary focus is high-volume refining and melting: The speed, energy efficiency, and low operating costs of induction technology will deliver the best return on investment.

- If your primary focus is operator safety and a smaller footprint: Compact, self-contained induction units provide a much safer and cleaner working environment compared to open-flame or older resistance methods.

Ultimately, induction technology has become the industry standard for precious metals because it provides a superior level of control over the process, directly protecting the value of the material.

Summary Table:

| Feature | Benefit for Precious Metals |

|---|---|

| Internal Heating | Prevents contamination, ensures purity |

| Temperature Precision | Allows exact alloy creation, reduces waste |

| Energy Efficiency | Lowers operating costs, increases throughput |

| Natural Stirring | Ensures homogeneous melts without impurities |

Ready to enhance your precious metals processing with advanced induction furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions tailored for your lab's unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by deep customization capabilities. Contact us today via our contact form to discuss how we can help you achieve superior purity, efficiency, and cost savings in your operations!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors