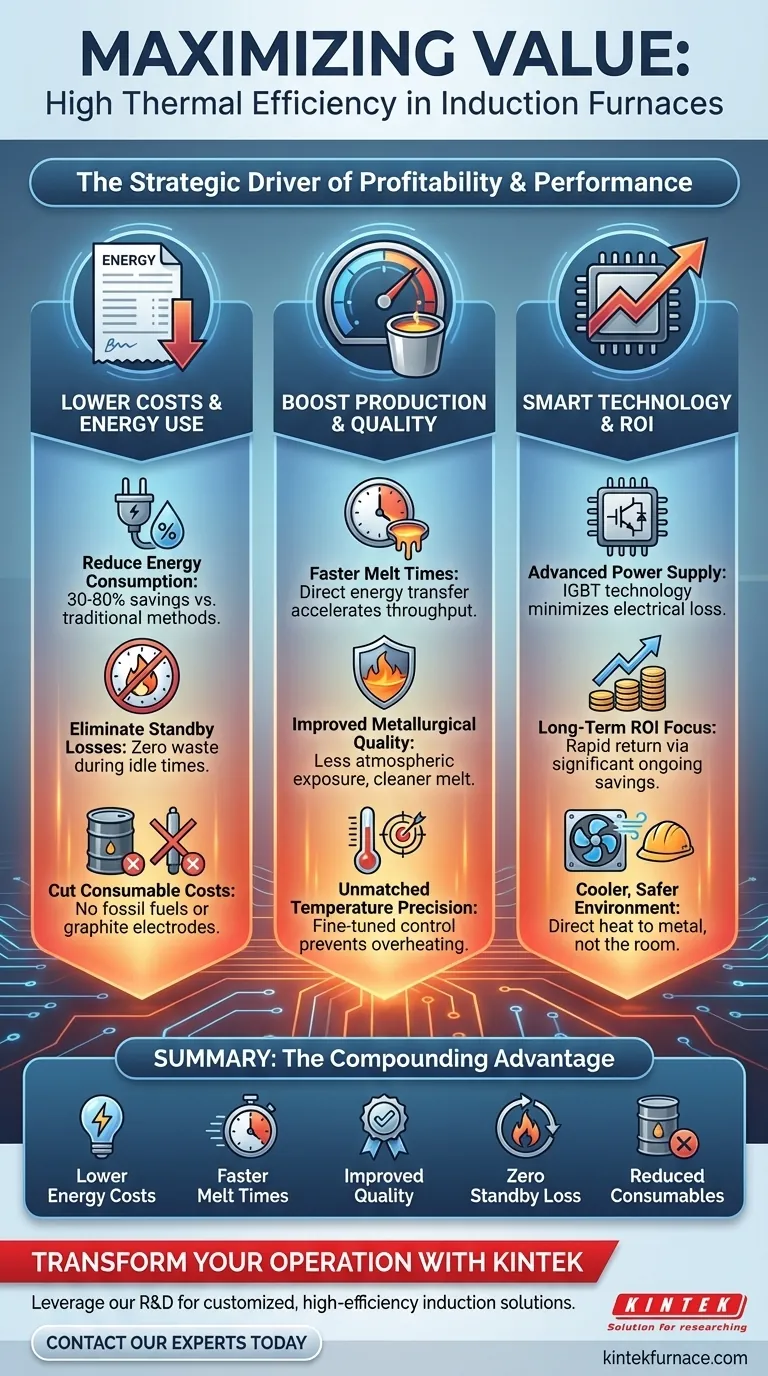

For any industrial melting operation, high thermal efficiency in an induction furnace is the primary driver of profitability and performance. This efficiency ensures the maximum amount of electrical energy is converted directly into useful heat within the metal charge, minimizing waste. The direct result is significantly lower energy costs, faster production cycles, and a superior final product.

The core benefit of high thermal efficiency is not just saving energy; it is a compounding advantage. By converting power into productive heat more effectively, it simultaneously cuts operational costs, accelerates production speed, and improves metallurgical quality, transforming it from a simple metric into a strategic asset.

The Direct Impact on Costs and Energy

High efficiency is most immediately felt on the balance sheet. Inefficient systems bleed energy, which directly translates to wasted operational expenditure.

Lowering Energy Consumption

Modern, high-efficiency induction furnaces can deliver energy savings of 30% to 80% compared to traditional fuel-fired methods. This is because the heat is generated within the metal itself, rather than being transferred from an external, often wasteful, source.

Eliminating Standby Losses

Unlike conventional furnaces that must be kept hot even when idle, induction furnaces have zero standby heat loss. They consume significant power only during the active melting process, drastically cutting energy waste during charging, tapping, or shift changes.

Reducing Consumable Costs

Induction melting eliminates the recurring cost and logistical burden of fossil fuels and combustion systems. Furthermore, it does not require consumable graphite electrodes, which are a significant operational expense in arc furnaces.

How Efficiency Boosts Production and Quality

Beyond cost savings, thermal efficiency is a powerful lever for improving the speed and quality of your output. More effective heating fundamentally changes the melting process for the better.

Faster Melt Times and Higher Throughput

The most direct operational benefit is speed. When more energy is efficiently converted to heat in the charge, the metal reaches its target temperature faster. This reduction in melt time directly increases the furnace's throughput (tons per hour), boosting overall plant capacity.

Improved Metallurgical Quality

Speed has a critical impact on quality. Faster melting reduces the time the molten metal is exposed to the atmosphere, which minimizes metal loss from oxidation and prevents undesirable changes like decarburization. The result is a cleaner melt with a higher yield.

Unmatched Temperature Precision

High thermal efficiency enables incredibly responsive and precise temperature control. Because energy transfer is so direct, the power supply can make immediate, fine-tuned adjustments, preventing overheating and ensuring the melt chemistry remains consistent and within specification.

Understanding the Trade-offs and Key Technologies

Achieving high efficiency is a result of specific design choices. Understanding these factors is critical for making an informed investment.

The Role of Frequency and Power Supply

Modern efficiency gains are largely driven by advanced power supplies. Systems using IGBT (Insulated-Gate Bipolar Transistor) technology are vastly superior to older SCR-based units because they convert line power with minimal electrical losses. These are often paired with medium-frequency operation, which optimizes the heating effect for a wide range of metals.

Initial Investment vs. Long-Term ROI

A high-efficiency induction furnace often carries a higher initial capital cost. However, this must be evaluated against the Total Cost of Ownership (TCO). The significant, ongoing savings in energy, consumables, and improved yield typically provide a rapid return on the initial investment.

A Cooler, Safer Work Environment

A furnace that directs heat into the metal instead of the surrounding air creates a dramatically cooler and safer workspace. This reduction in ambient heat improves operator comfort and reduces the risk of heat-related stress and accidents.

Making the Right Choice for Your Operation

Choosing a furnace requires aligning its technical specifications with your primary business goals. The efficiency rating is a key indicator of its potential to meet those objectives.

- If your primary focus is cost reduction: Prioritize furnaces with the highest electrical efficiency (kWh/ton) and modern IGBT power supplies to minimize long-term energy and consumable costs.

- If your primary focus is production throughput: Look for a system whose high efficiency delivers the fastest possible melt times, directly boosting your plant's output without expanding its physical footprint.

- If your primary focus is material quality: Select a furnace where efficiency enables rapid melting and precise temperature control, giving you the tools to minimize oxidation and achieve consistent, high-purity results.

Ultimately, investing in high thermal efficiency is an investment in a more productive, predictable, and sustainable operation.

Summary Table:

| Key Benefit | Direct Impact |

|---|---|

| Lower Energy Consumption | Saves 30-80% on energy costs vs. traditional methods. |

| Faster Melt Times | Increases throughput and overall plant capacity. |

| Improved Metallurgical Quality | Reduces oxidation and ensures precise temperature control. |

| Zero Standby Losses | Eliminates energy waste during idle periods. |

| Reduced Consumable Costs | No need for fossil fuels or graphite electrodes. |

Ready to transform your melting operation with superior thermal efficiency?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, high-efficiency induction furnace solutions. Our deep customization capabilities ensure your system is precisely engineered to maximize your ROI through significant energy savings, faster production cycles, and improved product quality.

Contact our experts today to discuss how we can optimize your melting process.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors