In essence, vacuum casting is a manufacturing process that uses a vacuum to draw a liquid resin, typically polyurethane, into a flexible silicone mold. The key difference from conventional casting is its use of soft, silicone molds instead of hard, metal tooling. This makes it ideal for producing small batches of high-fidelity plastic or rubber-like parts.

The choice between vacuum casting and conventional casting is not about which is superior, but which aligns with your goal. Vacuum casting excels at low-volume, high-detail prototyping, while conventional methods are built for high-volume mass production.

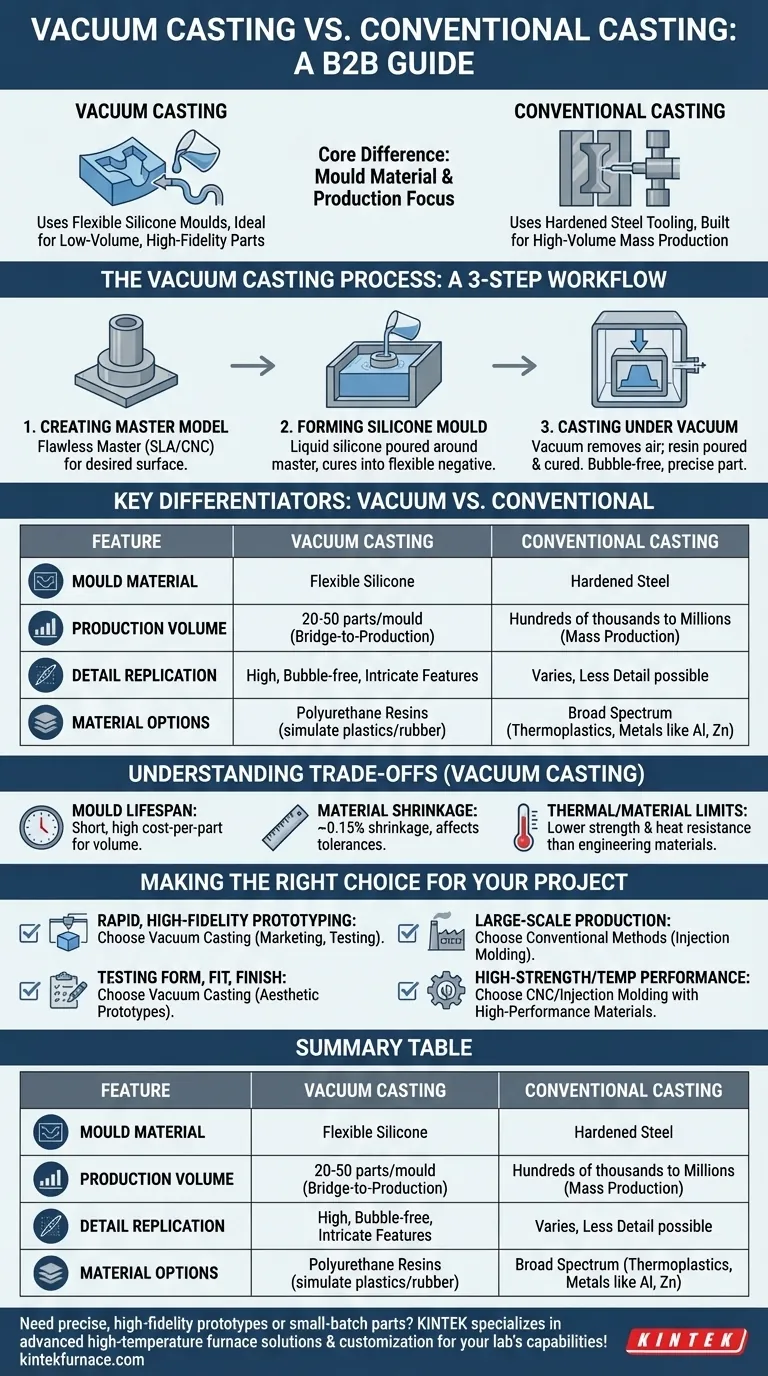

The Vacuum Casting Process: A Step-by-Step Guide

To understand its unique benefits, it's helpful to visualize the workflow. The process is precise and methodical, revolving around the creation of a perfect negative of the final part.

Step 1: Creating the Master Model

The process begins with a flawless master model. This is typically created using a high-resolution process like 3D printing (SLA) or CNC machining and is meticulously finished to achieve the desired surface quality.

Step 2: Forming the Silicone Mould

The master model is suspended inside a casting box, and liquid silicone is poured around it. After the silicone cures, it is carefully cut into two halves, and the master model is removed. This leaves a hollow cavity that is an exact negative impression of the original part.

Step 3: Casting Under Vacuum

The two-part silicone mold is reassembled, and a specialized polyurethane resin is mixed. The mold and the resin are then placed inside a vacuum chamber. The vacuum removes all air from the chamber, the mold cavity, and the liquid resin itself, preventing air bubbles from forming in the final part.

The resin is then poured into the mold while still under vacuum, ensuring it fills every intricate detail. Once filled, the mold is moved to a curing oven to solidify the part before it is de-molded.

Key Differentiators: Vacuum vs. Conventional Casting

The fundamental differences in tooling and process lead to distinct applications, costs, and outcomes.

Mould Material: Silicone vs. Steel

Vacuum casting uses flexible silicone molds. This allows for parts with complex geometries and even slight undercuts, as the mold can be flexed to release the part.

Conventional methods, like injection molding or die casting, use hardened steel molds. These are incredibly durable but are also rigid, expensive, and time-consuming to produce.

Production Volume: Prototypes vs. Mass Production

A single silicone mold can typically produce only 20-50 parts before it begins to degrade. This makes vacuum casting an ideal bridge-to-production tool, perfect for small batches.

Steel molds are built to last for hundreds of thousands or even millions of cycles, making conventional casting the only viable option for true mass production.

Part Complexity and Detail

The combination of a liquid resin and a vacuum environment allows for extraordinary detail replication. The vacuum ensures that the material flows into even the finest features, creating a bubble-free part with a high-quality surface finish that mirrors the master model.

Material Compatibility

Vacuum casting is primarily used with a wide range of polyurethane (PU) resins. These resins can be formulated to simulate the properties of production-grade plastics like ABS, nylon, or rubber of various hardnesses.

Conventional casting covers a much broader spectrum, from thermoplastics in injection molding to metals like aluminum and zinc in die casting.

Understanding the Trade-offs of Vacuum Casting

While powerful, this process is not a universal solution. Understanding its limitations is critical for making an informed decision.

Mould Lifespan and Cost

The short lifespan of a silicone mold is its primary limitation for volume production. While the initial tooling cost is significantly lower than for a steel mold, the cost-per-part remains relatively high.

Material Shrinkage

Polyurethane resins experience a degree of shrinkage as they cure, typically around 0.15%. This must be accounted for in the design of the master model, especially for parts requiring tight tolerances.

Thermal and Material Limitations

The parts produced are made from thermoset polyurethanes, which do not have the same thermal or mechanical strength as many production-grade engineering thermoplastics or metals. The process is not suitable for creating parts intended for high-temperature applications.

Making the Right Choice for Your Project

Selecting the correct process depends entirely on your project's stage and ultimate goal.

- If your primary focus is rapid, high-fidelity prototyping: Vacuum casting is the perfect choice for creating a small series of production-quality plastic parts for marketing, user testing, or functional validation.

- If your primary focus is large-scale production: Conventional methods like injection molding are the clear and most cost-effective path for producing thousands of parts.

- If your primary focus is testing form, fit, and finish: The exceptional surface quality and detail of vacuum casting make it superior for creating aesthetic prototypes that look and feel like a final product.

- If your primary focus is high-strength or high-temperature performance: You must look beyond vacuum casting to processes like CNC machining in metal or injection molding with high-performance thermoplastics.

Ultimately, understanding the unique strengths and weaknesses of each process empowers you to select the most efficient tool for the job.

Summary Table:

| Feature | Vacuum Casting | Conventional Casting |

|---|---|---|

| Mould Material | Flexible silicone | Hardened steel |

| Production Volume | 20-50 parts per mold | Hundreds of thousands to millions |

| Ideal Use | Prototyping, small batches | Mass production |

| Detail Replication | High, bubble-free | Varies, less detail in some cases |

| Material Options | Polyurethane resins | Broad (plastics, metals) |

| Tooling Cost | Low | High |

| Part Strength | Lower thermal/mechanical | Higher for engineering materials |

Need precise, high-fidelity prototypes or small-batch parts? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring superior performance for your vacuum casting or other processes. Contact us today to discuss how we can enhance your lab's capabilities!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- What frequency ranges are used in induction heating for different applications? Optimize Your Process with the Right Frequency

- What role does a vacuum induction furnace play in M2 steel refining? Achieve Deep Deoxidation and Purity

- What two core heating methods are primarily used in the preparation of ultrafine magnesium powder? Choose the Right Method for Your Process

- What future advancements are expected in IGBT technology for induction melting? Higher Power Density & Intelligent Control

- Why is a vacuum arc furnace necessary for Fe60Co10-xNi15Cr15Six? Ensure High-Entropy Alloy Purity

- What is the working process of an induction furnace? Discover Contactless, High-Efficiency Metal Melting

- What safety benefits does induction heating provide in the workplace? Achieve a Flameless, Contained Heating Process

- What are the advantages and uses of induction furnaces in foundries? Achieve Fast, Clean, and Precise Metal Melting