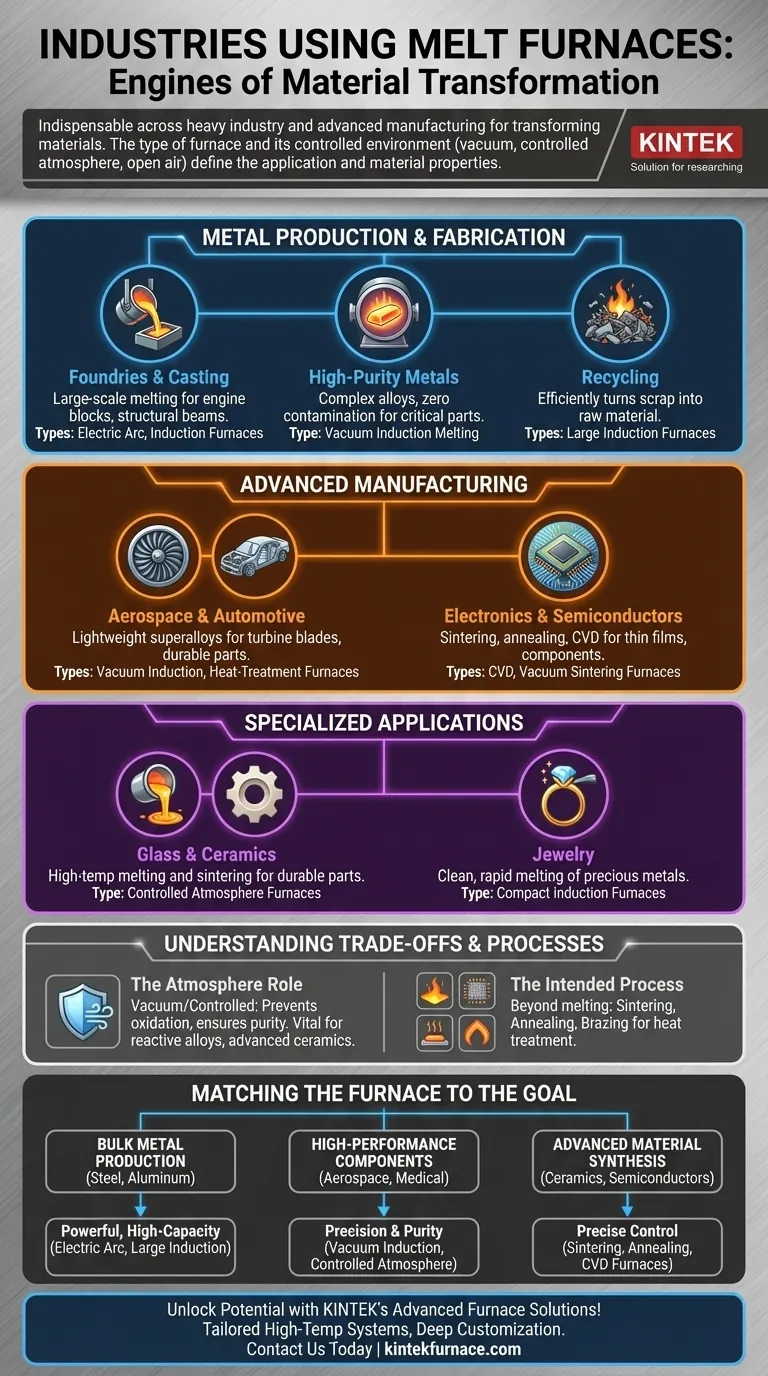

At their core, melt furnaces are the engines of material transformation, making them indispensable across nearly every heavy industry and advanced manufacturing sector. They are used extensively in metalworking, foundries (steel and aluminum), recycling, aerospace, automotive, and electronics, as well as in the production of glass, ceramics, and even jewelry.

The term "melt furnace" is a broad classification. The specific type of furnace and its controlled environment—whether vacuum, controlled atmosphere, or open air—is what truly defines its industrial application and dictates the properties of the final material.

The Foundation: Metal Production and Fabrication

The most common and large-scale use of melt furnaces is in the creation and shaping of metals. This forms the backbone of global infrastructure and manufacturing.

Foundries and Metal Casting

Foundries are the primary users of large-scale melting furnaces. Here, raw materials like iron, steel, and aluminum are melted in vast quantities to be cast into fundamental industrial and consumer products.

These castings range from engine blocks in the automotive industry to structural beams for construction and casings for industrial machinery.

High-Purity Metals and Alloys

For more demanding applications, standard melting is not enough. Vacuum induction melting furnaces are used to create highly pure metals and complex alloys free from contamination.

This process is critical for producing materials that must withstand extreme conditions, such as intricate valves for chemical processing or specialized alloys for the energy sector.

Recycling and Scrap Metal Processing

Melt furnaces are the heart of the metal recycling industry. They efficiently melt down scrap steel, aluminum, and other metals, turning waste into valuable raw material for new production cycles. This is a cornerstone of the circular economy.

Advanced Manufacturing and High-Performance Materials

Beyond bulk production, specialized furnaces are critical for creating the high-performance materials that drive modern technology.

Aerospace and Automotive Components

The aerospace industry relies on furnaces to produce lightweight, high-strength superalloys for jet engine turbine blades and structural components. Precision and material integrity are paramount.

Similarly, the automotive sector uses advanced heat-treatment processes in furnaces to create stronger, more durable, and safer vehicle parts.

Electronics and Semiconductors

In the electronics industry, furnaces are used for more than just melting. Processes like sintering, annealing, and chemical vapor deposition (CVD) are essential.

CVD furnaces, for example, are used to deposit ultra-thin films onto semiconductor wafers. Vacuum sintering furnaces are used to fuse metallic or ceramic powders into solid components for advanced electronic devices.

Beyond Metals: Specialized Industrial Applications

The need to control extreme heat extends far beyond the world of metallurgy.

Glass and Ceramics Manufacturing

The production of glass requires melting silica sand and other ingredients at high temperatures. Similarly, controlled atmosphere furnaces are essential in the ceramics industry for processes like sintering, which turns powders into hard, durable ceramic parts.

These advanced ceramics are used in everything from electronics and body armor to medical implants.

Jewelry and Precious Metals

On a smaller, more precise scale, the jewelry industry uses compact induction furnaces. These allow for the clean, rapid melting of precious metals like gold, silver, and platinum, ensuring purity and minimizing material loss during casting.

Understanding the Trade-offs: Not All Furnaces Are Equal

Choosing a furnace is not about the industry, but about the specific material process required. The key differentiators are the atmosphere, the heating method, and the intended process.

The Role of the Atmosphere

A vacuum or controlled atmosphere is used to prevent reactions between the molten material and the air, such as oxidation. This is vital for producing high-purity metals, reactive alloys (like titanium), and advanced ceramics where any contamination would degrade performance.

The Intended Process

The term "furnace" often covers more than just melting. Sintering (fusing powders with heat below the melting point), annealing (softening material to improve workability), and brazing (joining components with a filler metal) are all critical heat-treatment processes performed in industrial furnaces.

Matching the Furnace to the Industrial Goal

Your choice of furnace technology is dictated entirely by the desired properties of the end product.

- If your primary focus is bulk metal production (steel, aluminum): Your need is for powerful, large-capacity systems like electric arc or large induction furnaces designed for high throughput.

- If your primary focus is high-performance components (aerospace, medical): Your need is for precision and purity, pointing toward vacuum induction or controlled atmosphere furnaces.

- If your primary focus is advanced material synthesis (ceramics, semiconductors): Your need is for precise temperature and atmosphere control, found in specialized sintering, annealing, or CVD furnaces.

Ultimately, understanding the specific material transformation you need to achieve is the key to selecting the right thermal processing technology.

Summary Table:

| Industry | Common Applications | Key Furnace Types |

|---|---|---|

| Metal Production & Fabrication | Casting engine blocks, structural beams | Electric Arc, Induction Furnaces |

| Recycling | Melting scrap steel and aluminum | Large Induction Furnaces |

| Aerospace & Automotive | Producing superalloys for turbine blades | Vacuum Induction Furnaces |

| Electronics & Semiconductors | Sintering, annealing, CVD for components | CVD, Vacuum Sintering Furnaces |

| Glass & Ceramics | Manufacturing durable parts and glass | Controlled Atmosphere Furnaces |

| Jewelry | Melting precious metals like gold and silver | Compact Induction Furnaces |

Unlock the full potential of your industrial processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature systems. Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed to meet your unique needs, whether you're in metalworking, aerospace, electronics, or ceramics. Benefit from our strong deep customization capability to achieve precise temperature control, contamination-free environments, and superior material outcomes. Ready to enhance your efficiency and innovation? Contact us today for a consultation and discover how we can support your specific applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Induction Melting Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing