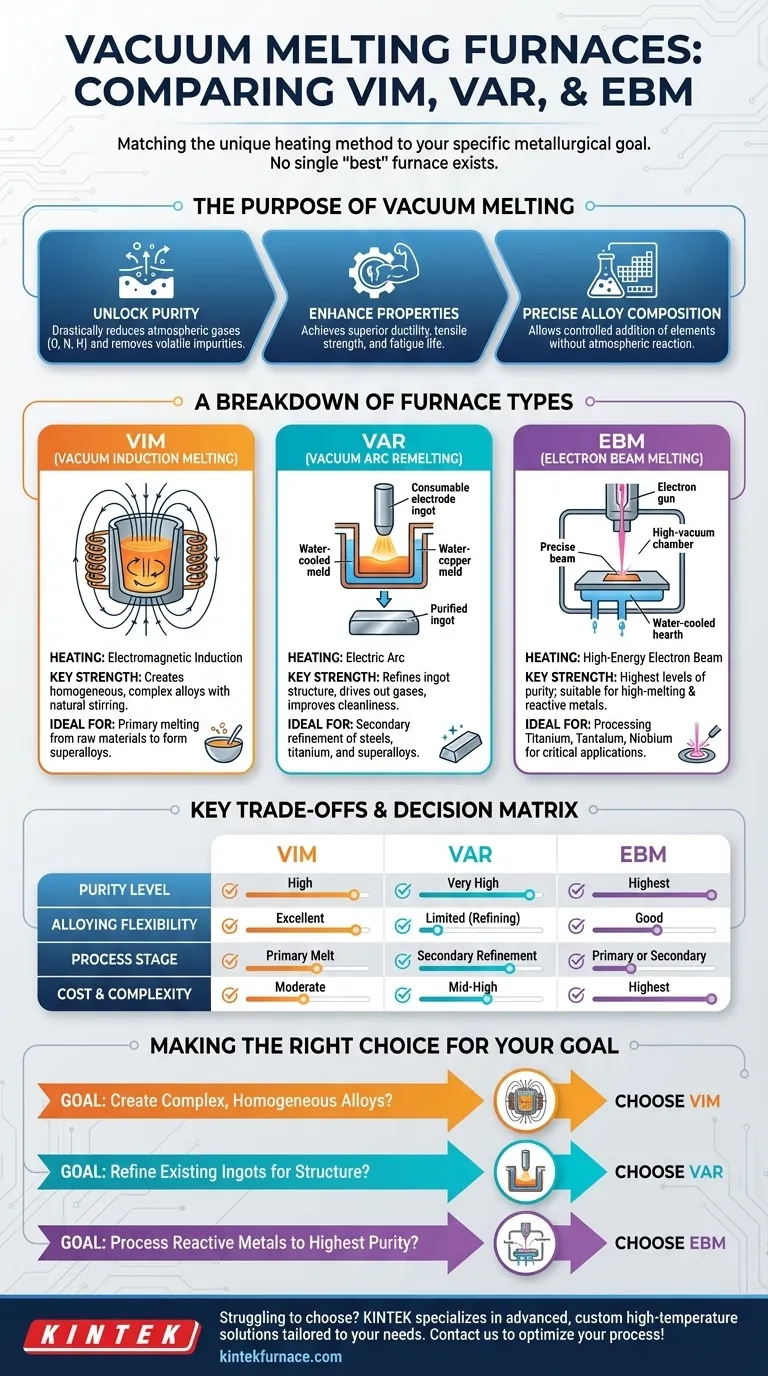

At its core, vacuum melting technology is defined by three primary furnace types: Vacuum Induction Melting (VIM), Vacuum Arc Remelting (VAR), and Electron Beam Melting (EBM). These furnaces achieve similar goals—melting metal in a controlled, contamination-free environment—but accomplish it through fundamentally different heating mechanisms. The choice between them depends entirely on the specific material being processed and the desired outcome, whether it's alloy creation, purification, or handling reactive metals.

The central decision is not about finding the single "best" furnace, but about matching the furnace's unique heating method to your specific metallurgical goal. VIM excels at alloying, VAR excels at refining ingot structure, and EBM achieves the highest levels of purity for the most challenging materials.

The Purpose of Melting in a Vacuum

Before comparing the furnace types, it's critical to understand why a vacuum environment is necessary. Operating under vacuum provides several distinct advantages over melting in open air.

Unlocking Material Purity

A vacuum environment drastically reduces the atmospheric gases like oxygen, nitrogen, and hydrogen that can dissolve in molten metal. This process, known as degassing, is crucial for preventing defects.

It also helps remove volatile impurities and oxides from the melt, resulting in a cleaner, higher-quality final product.

Enhancing Material Properties

Metals produced in a vacuum exhibit superior mechanical characteristics. By minimizing impurities and controlling the solidification process, you achieve enhanced ductility, tensile strength, and fatigue life.

This level of control is non-negotiable for high-performance materials used in critical applications like aerospace and medical devices.

Achieving Precise Alloy Composition

The controlled environment allows for the precise addition of alloying elements without the risk of them reacting with the atmosphere. This ensures the final material has a consistent, predictable, and repeatable chemical composition.

A Breakdown of Furnace Types

Each furnace type uses a distinct method to generate heat. This fundamental difference dictates its primary application and its strengths.

Vacuum Induction Melting (VIM)

A VIM furnace uses electromagnetic induction to heat the metal. An induction coil surrounds a refractory-lined crucible containing the raw material. The alternating current in the coil induces powerful eddy currents within the metal, generating heat and causing it to melt.

This method produces a natural stirring action in the molten bath, making VIM the ideal choice for creating homogeneous, complex alloys with precise chemical compositions from scratch.

Vacuum Arc Remelting (VAR)

A VAR furnace is primarily a refining process, not a primary melting process. It starts with a solid ingot of pre-alloyed material (often produced in a VIM furnace), which acts as a large consumable electrode.

A high-current electric arc is struck between this electrode and a water-cooled copper mold. The arc's intense heat melts the tip of the electrode, and the metal drips down to solidify in the mold. This process drives out dissolved gases and pushes impurities to the outside of the new ingot, resulting in exceptional cleanliness and a highly controlled grain structure.

Electron Beam Melting (EBM)

An EBM furnace uses a high-energy beam of electrons as its heat source, all within a high-vacuum chamber. The electron gun generates and accelerates electrons, which are then precisely guided by magnetic fields to strike and melt the material.

This method can generate extremely high temperatures, making it suitable for high-melting-point and reactive metals like titanium, tantalum, and niobium. The precise beam control and high vacuum level allow for the highest degree of purification.

Understanding the Key Trade-offs

No single furnace is superior in all aspects. The choice involves balancing the need for purity, alloying flexibility, and cost.

Purity vs. Alloying Control

VIM offers unparalleled control for creating alloys but is limited in ultimate purity, as the molten metal is in direct contact with the furnace's refractory crucible, which can be a source of contamination.

VAR and EBM, in contrast, are designed for maximum purification. By using a water-cooled copper hearth or mold, they avoid contact with refractories, leading to a cleaner final product. EBM provides the absolute highest level of purification due to its high vacuum and precise heating.

Process Stage: Primary Melt vs. Secondary Refinement

VIM is the workhorse for primary melting—turning raw materials into a liquid alloy.

VAR is almost exclusively a secondary remelting process. Its purpose is to take a solid ingot and refine it to improve its purity and internal structure, not to create an alloy from individual components.

EBM is versatile and can be used for both primary melting of raw materials and secondary refinement of ingots.

Cost, Complexity, and Throughput

VIM furnaces are generally the most common and cost-effective for a wide range of standard alloys, offering high throughput and reliable operation.

VAR represents a moderate level of cost and complexity and is an essential second step for producing high-performance materials.

EBM is the most complex and expensive technology. It requires a higher vacuum level and sophisticated electron gun systems, making it a specialized tool for applications demanding the highest material performance.

Making the Right Choice for Your Goal

Your decision should be guided by the final properties your material requires.

- If your primary focus is creating complex, homogeneous superalloys from raw materials: VIM is the ideal choice for its exceptional compositional control and inherent stirring action.

- If your primary focus is refining existing ingots for maximum purity and structural integrity: VAR is the industry standard for secondary remelting of steels, superalloys, and titanium alloys.

- If your primary focus is processing highly reactive or high-melting-point metals to the highest possible purity: EBM provides capabilities that other methods cannot match, making it essential for advanced aerospace and medical applications.

Ultimately, selecting the correct vacuum furnace is about choosing the right tool for a specific metallurgical objective.

Summary Table:

| Furnace Type | Primary Use | Key Strengths | Ideal For |

|---|---|---|---|

| VIM (Vacuum Induction Melting) | Primary melting and alloy creation | Homogeneous alloys, precise composition control | Creating complex superalloys from raw materials |

| VAR (Vacuum Arc Remelting) | Secondary refinement | High purity, controlled grain structure | Refining ingots for steels, superalloys, and titanium |

| EBM (Electron Beam Melting) | Primary melting and refinement | Highest purity, handles reactive/high-melting-point metals | Processing titanium, tantalum for aerospace and medical |

Struggling to choose the right vacuum melting furnace for your lab? KINTEK specializes in advanced high-temperature solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise alignment with your experimental goals—whether you're refining alloys, enhancing purity, or handling reactive metals. Contact us today to discuss how our expertise can optimize your metallurgical processes and deliver superior results!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab