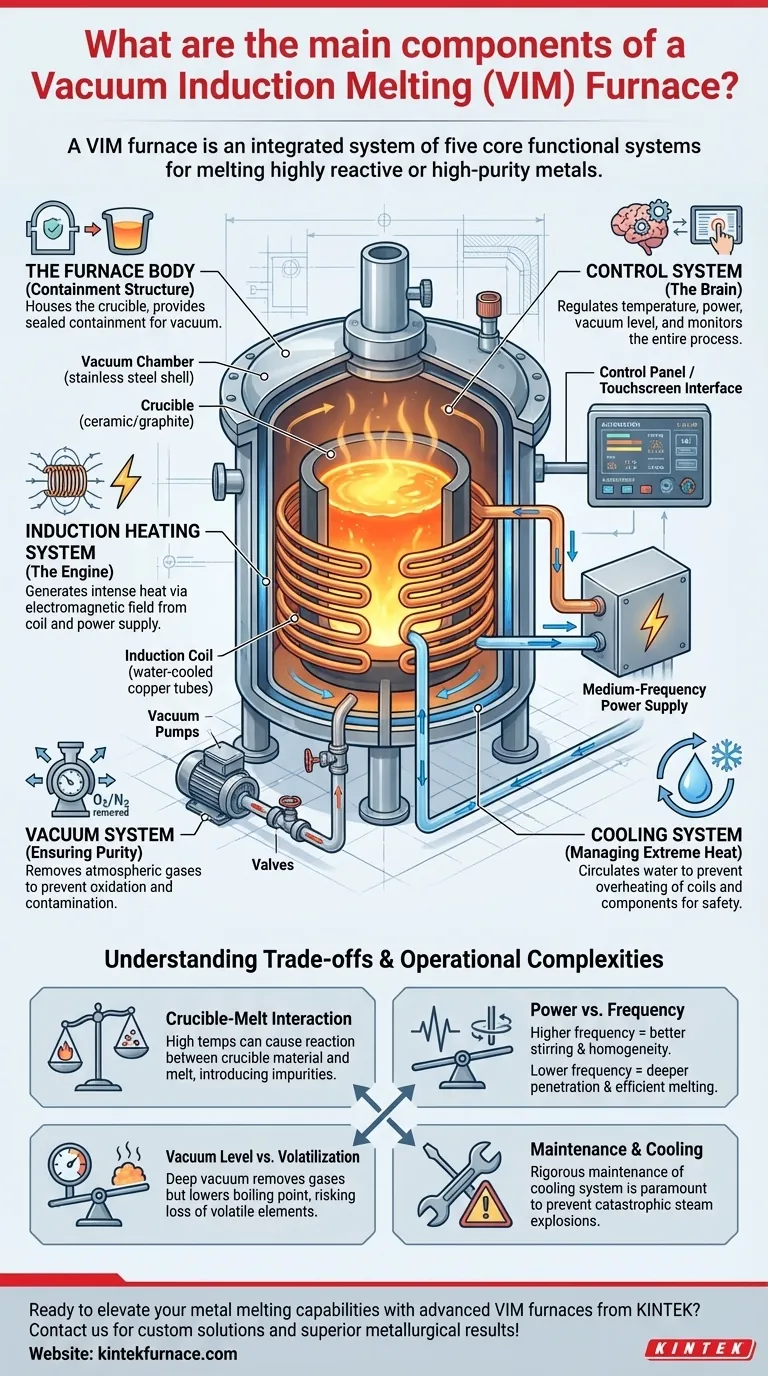

In essence, a vacuum induction melting (VIM) furnace is built around five core functional systems. These are the furnace body which houses the crucible, the induction heating system powered by a medium-frequency supply, a vacuum system to create a controlled atmosphere, a water cooling system for thermal management, and an electrical control system for precise operation. Each system works in concert to melt metals and alloys in a clean, gas-free environment.

A VIM furnace is not just a collection of parts; it is an integrated system designed for a single purpose: melting highly reactive or high-purity metals. Each component addresses a fundamental challenge—heating, contamination, and safety—to produce superior metallurgical results.

Deconstructing the VIM Furnace: A System-by-System Breakdown

To truly understand a VIM furnace, it's best to analyze it as a set of interdependent systems, each with a specific role in the melting process.

The Furnace Body: The Containment Structure

The furnace body is the physical, sealed enclosure where the melting takes place. It consists of two key parts.

First is the vacuum chamber, an airtight shell typically made of stainless steel that can withstand both high vacuum and internal pressure.

Inside the chamber sits the crucible, a high-temperature-resistant container made of materials like ceramic or graphite. The crucible is what directly holds the metal charge being melted.

The Induction Heating System: The Engine of the Furnace

This system generates the intense heat required for melting, without direct contact with the metal.

The core of this system is the induction coil, a set of water-cooled copper tubes that surround the crucible.

The coil is energized by a medium frequency power supply, which converts standard utility power into high-frequency alternating current (AC), often in the range of 50 Hz to 1100 kHz. This current in the coil generates a powerful electromagnetic field, which in turn induces immense heat directly within the metal charge.

The Vacuum System: Ensuring Purity

The vacuum system is what separates a VIM furnace from a standard induction furnace. Its primary job is to remove atmospheric gases like oxygen and nitrogen from the chamber.

This prevents the molten metal from reacting with the atmosphere, which is crucial for preventing oxidation and contamination. The system consists of powerful vacuum pumps and a series of valves to control the pressure inside the chamber.

The Cooling System: Managing Extreme Heat

A VIM furnace generates tremendous heat, and managing it is critical for safety and operational longevity.

A closed-loop water cooling system is used to circulate water through the copper induction coils, the power supply, and often the walls of the vacuum chamber itself. This prevents the components from overheating and failing.

The Control System: The Brain of the Operation

The entire process is managed by an integrated electrical control system.

This system, often operated via a control panel or touchscreen interface, allows for precise regulation of temperature, power input, and vacuum level. Modern systems offer a high degree of automation, monitoring the melt and ensuring the final product meets exact specifications.

Understanding the Trade-offs and Operational Complexities

While powerful, the VIM process involves balancing several competing factors. Understanding these trade-offs is key to achieving desired results.

Crucible-Melt Interaction

The crucible is not perfectly inert. At high temperatures, a chemical reaction can occur between the crucible material and the molten metal, potentially introducing trace impurities. The choice of crucible material is a critical decision based on the alloy being produced.

Power vs. Frequency

The characteristics of the power supply have a direct impact on the melt. A higher frequency tends to create more vigorous stirring of the molten metal, which promotes a homogeneous, evenly mixed alloy. A lower frequency allows the electromagnetic field to penetrate deeper, which is more efficient for melting larger charges.

Vacuum Level vs. Volatilization

A deep vacuum is excellent for removing dissolved gases like oxygen. However, it also lowers the boiling point of all elements in the melt. This can cause highly volatile alloying elements (such as manganese, zinc, or magnesium) to "boil off" and be lost to the vacuum, altering the final chemical composition of the alloy.

Maintenance and Cooling Integrity

The water cooling system is a non-negotiable safety component. A leak inside the vacuum chamber during operation can cause a catastrophic steam explosion. Therefore, rigorous and preventative maintenance of all cooling lines and seals is paramount.

Making the Right Choice for Your Application

The specific design and operation of a VIM furnace depend heavily on the desired outcome.

- If your primary focus is ultimate purity: You'll prioritize a high-end vacuum system and careful selection of crucible material to minimize contamination.

- If your primary focus is creating complex alloys: You will need a sophisticated control system and a power supply that allows for precise temperature and stirring control.

- If your primary focus is large-scale production: The efficiency of the power supply, the durability of the furnace body, and the reliability of the cooling system are your most critical concerns.

Understanding how these components function as an integrated system is the first step toward mastering the production of high-performance materials.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Furnace Body | Houses the crucible and provides containment | Vacuum chamber, crucible for holding metal |

| Induction Heating System | Generates heat for melting | Induction coil, medium-frequency power supply |

| Vacuum System | Removes gases to prevent contamination | Vacuum pumps, valves for controlled atmosphere |

| Cooling System | Manages heat for safety and longevity | Closed-loop water cooling for coils and components |

| Control System | Regulates operation and monitors the process | Control panel, automation for precise settings |

Ready to elevate your metal melting capabilities? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our VIM furnaces, part of a product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are complemented by strong deep customization to precisely meet your unique experimental needs for high-purity and complex alloys. Contact us today to discuss how we can optimize your melting processes and deliver superior metallurgical results!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity