In short, IGBT induction melting furnaces are foundational in nearly every sector that processes metal, from high-volume steel and aluminum production to the precision-driven aerospace and electronics industries. Their adoption is widespread due to their superior energy efficiency, rapid melting capabilities, and precise temperature control, which are critical for modern manufacturing standards.

The core reason for the broad adoption of IGBT induction furnaces is not just their ability to melt metal, but their capacity to deliver specific, high-value outcomes. These furnaces provide the control, purity, and efficiency necessary for industries producing everything from automotive parts to advanced aerospace superalloys.

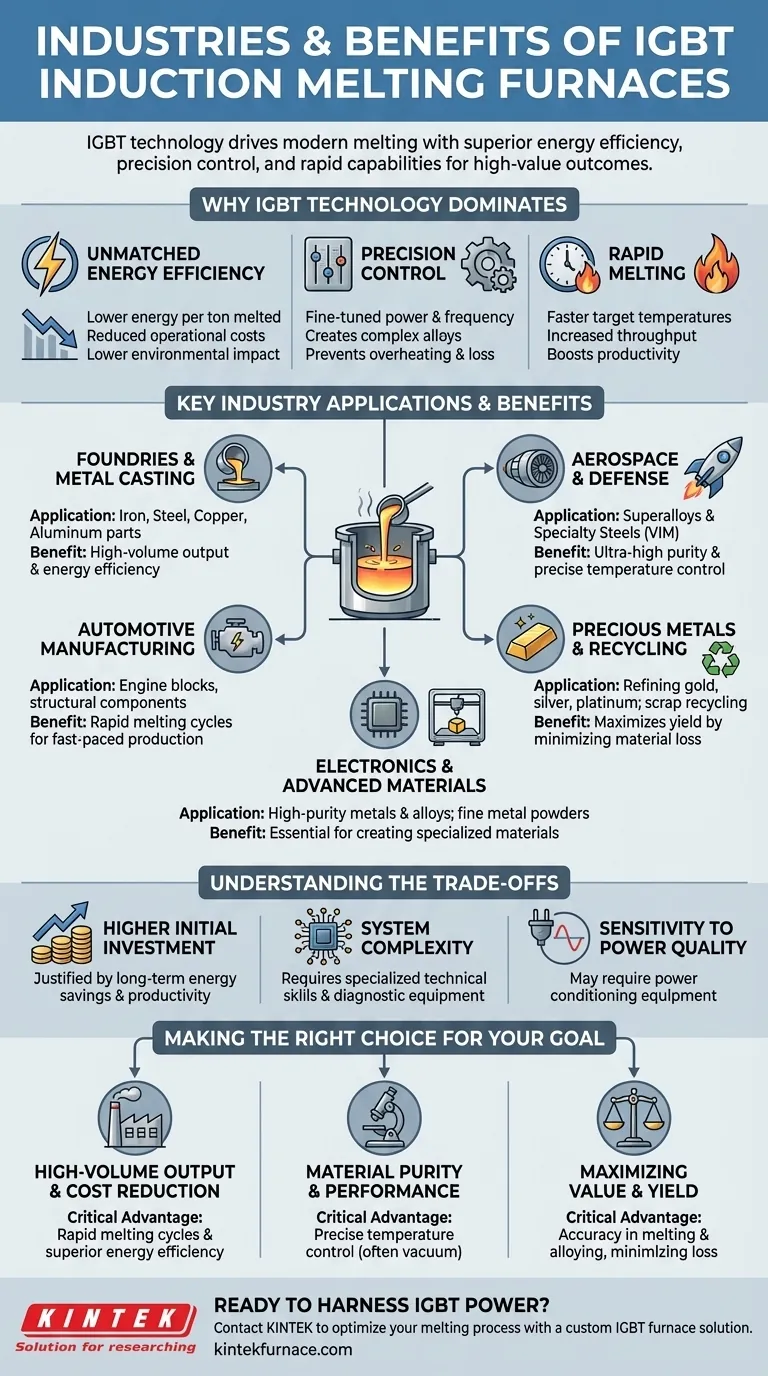

Why IGBT Technology Dominates Modern Melting

The "IGBT" (Insulated Gate Bipolar Transistor) is the solid-state power supply that drives the modern induction furnace. It represents a significant leap from older, less efficient technologies, offering distinct advantages that modern industries depend on.

Unmatched Energy Efficiency

IGBT power supplies convert electricity into a high-frequency current far more efficiently than legacy systems. This directly translates to lower energy consumption per ton of metal melted, reducing operational costs and environmental impact.

Precision Temperature and Process Control

These systems allow for extremely fine-tuned control over power input and frequency. This precision is essential for creating complex alloys with specific properties, preventing overheating, and minimizing the loss of valuable alloying elements through oxidation.

Rapid Melting and Increased Throughput

IGBT furnaces achieve target temperatures much faster than traditional methods. This rapid melting cycle boosts productivity, allowing foundries and manufacturing plants to increase their output without a proportional increase in plant size or energy use.

Key Industry Applications

The benefits of IGBT technology make it indispensable across a spectrum of industries, each leveraging its unique capabilities.

Foundries and Metal Casting

This is the most common application. Foundries use IGBT furnaces to melt iron, steel, copper, and aluminum for casting into parts. The speed and energy efficiency are critical for the high-volume, cost-sensitive nature of this industry.

Aerospace and Defense

This sector relies on IGBT furnaces, particularly vacuum induction melting (VIM) variants, to produce mission-critical components. These furnaces create the ultra-high-purity superalloys and specialty steels required for jet engines, rocket parts, and missile components that must perform under extreme conditions.

Automotive Manufacturing

From engine blocks to structural components, the automotive industry uses induction melting for consistent, high-volume production. The ability to quickly melt and alloy metals supports the fast-paced, quality-focused demands of automotive supply chains.

Precious Metals and Recycling

In refining gold, silver, and platinum, or recycling valuable scrap metal, minimizing material loss is paramount. The precise control of an IGBT furnace ensures complete melting and accurate alloying, maximizing the yield from expensive raw materials.

Electronics and Advanced Materials

The electronics industry uses highly controlled induction melting to produce high-purity metals and special alloys for components. This technology is also used to create fine metal powders for advanced applications like 3D printing and thermal spraying.

Understanding the Trade-offs

While highly advantageous, IGBT technology is not without its considerations. Acknowledging these factors is key to making an informed decision.

Higher Initial Investment

The upfront cost of an IGBT-powered induction furnace is typically higher than that of older, less efficient systems or traditional fuel-fired furnaces. This investment is justified by long-term savings in energy and increased productivity.

System Complexity

Modern solid-state electronics are more complex than older mechanical or thyristor-based systems. Maintenance and troubleshooting require specialized technical skills and diagnostic equipment.

Sensitivity to Power Quality

IGBT systems can be sensitive to fluctuations and harmonics in the electrical supply grid. Proper installation often requires power conditioning equipment to ensure reliable and long-term operation.

Making the Right Choice for Your Goal

Your application's primary driver will determine which benefit of an IGBT furnace is most critical.

- If your primary focus is high-volume output and cost reduction (Foundries, Automotive): The key benefits are rapid melting cycles and superior energy efficiency.

- If your primary focus is material purity and performance (Aerospace, Electronics, Medical): The non-negotiable feature is precise temperature control, often within a vacuum environment.

- If your primary focus is maximizing value and yield (Precious Metals, Recycling): The critical advantage is the furnace's accuracy in melting and alloying, which minimizes costly material loss.

Ultimately, choosing an IGBT induction furnace is an investment in control, efficiency, and the quality of your final product.

Summary Table:

| Industry | Primary Application | Key Benefit of IGBT Furnace |

|---|---|---|

| Foundries & Metal Casting | Melting iron, steel, copper, aluminum | High-volume output & energy efficiency |

| Aerospace & Defense | Vacuum melting of superalloys & specialty steels | Ultra-high purity & precise temperature control |

| Automotive Manufacturing | Engine blocks, structural components | Rapid melting cycles for fast-paced production |

| Precious Metals & Recycling | Refining gold, silver, platinum; recycling scrap | Maximizes yield by minimizing material loss |

| Electronics & Advanced Materials | Producing high-purity metals & alloys for components | Essential for creating specialized materials |

Ready to harness the power of IGBT induction melting for your specific application?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal processing solutions. Whether your goal is high-volume production, achieving ultra-high material purity, or maximizing yield from valuable materials, our team can develop a high-temperature furnace solution tailored to your unique requirements.

Our expertise includes customizing Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems to meet the precise demands of industries like aerospace, automotive, and precious metals processing.

Contact our experts today to discuss how we can optimize your melting process with a custom IGBT furnace solution.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing