In the medical field, precision is not a goal; it's a prerequisite. Vacuum furnaces are utilized to manufacture biocompatible implants and high-performance surgical tools that must meet the most stringent purity and performance standards. By heating materials in a controlled environment below atmospheric pressure, these furnaces prevent contamination and chemical reactions like oxidation, which is critical for medical-grade components.

The core reason for using vacuum furnaces in medicine is their ability to create an ultraclean, oxygen-free environment. This is the only way to guarantee the material purity and specific structural properties required for devices that must function safely and reliably inside the human body.

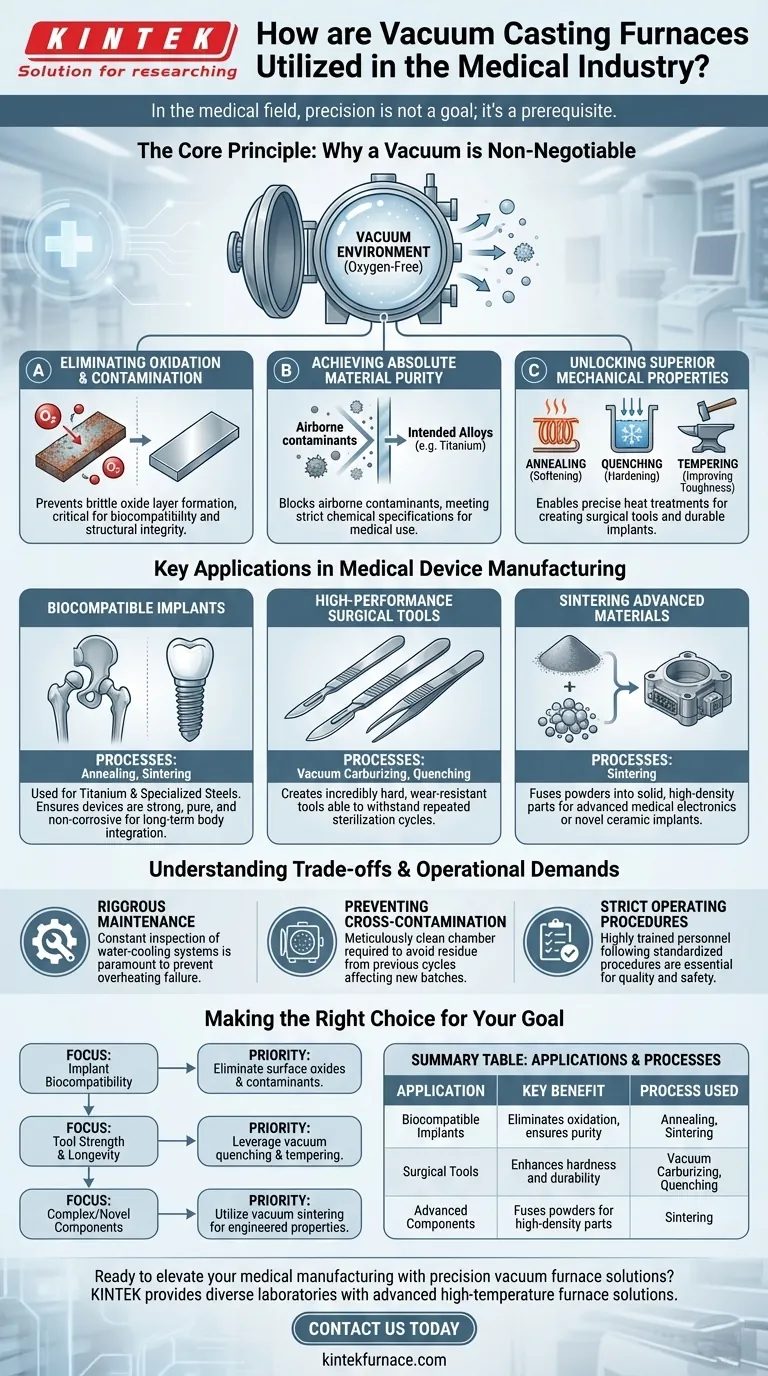

The Core Principle: Why a Vacuum is Non-Negotiable

A vacuum furnace's primary function is to remove the atmosphere—and specifically oxygen—from the heating chamber. This simple act has profound implications for medical manufacturing.

Eliminating Oxidation and Contamination

At high temperatures, most metals react with oxygen in a process called oxidation. This forms a brittle, impure oxide layer on the material's surface.

For a medical implant, such an oxide layer is unacceptable. It can compromise the device's structural integrity and, more critically, its biocompatibility, potentially leading to adverse reactions within the body. A vacuum environment eliminates this risk entirely.

Achieving Absolute Material Purity

The medical industry demands materials free from any foreign elements. A vacuum chamber prevents airborne contaminants from embedding into the material during high-temperature processing.

This ensures the final product—whether a titanium hip joint or a stainless steel scalpel—is composed only of its intended alloys, meeting the strict chemical specifications for medical use.

Unlocking Superior Mechanical Properties

Beyond purity, vacuum furnaces are essential for specific heat-treatment processes that enhance a material's physical characteristics.

Processes like annealing (softening), quenching (hardening), and tempering (improving toughness) can be performed with extreme precision. This control is vital for creating surgical tools that hold a sharp edge or implants that can withstand decades of mechanical stress.

Key Applications in Medical Device Manufacturing

The principles of vacuum processing are applied to create a range of critical medical products. The controlled environment is key to consistently achieving the required quality.

Manufacturing Biocompatible Implants

Vacuum furnaces are used to process materials like titanium alloys and specialized steels for orthopedic implants (hips, knees), dental implants, and spinal fusion cages. The process ensures these devices are strong, pure, and will not corrode or cause an immune response when placed in the body.

Forging High-Performance Surgical Tools

Surgical instruments must be incredibly hard, wear-resistant, and able to withstand repeated sterilization cycles.

Vacuum heat treatments, including vacuum carburizing (case hardening), are used to create a durable surface on tools while maintaining the core material's toughness, ensuring a long service life and reliable performance.

Sintering Advanced Materials

Vacuum furnaces are also used for sintering, a process where metal or ceramic powders are heated until they fuse into a solid, high-density part. This is essential for creating advanced components, such as parts for medical electronics or novel ceramic-based implants.

Understanding the Trade-offs and Operational Demands

While indispensable, operating a vacuum furnace is a demanding and precise discipline. It is not a simple "set and forget" process.

The Need for Rigorous Maintenance

The integrity of the system is paramount. The water-cooling systems must be inspected constantly to prevent the furnace from overheating. Any failure here can be catastrophic to both the furnace and the product.

Preventing Cross-Contamination

The vacuum chamber itself must be kept meticulously clean. Any residue from a previous cycle can vaporize during the next run, contaminating the new batch of materials. This is especially critical when switching between different types of alloys.

Adherence to Strict Operating Procedures

Operating a vacuum furnace requires highly trained personnel who follow standardized procedures without deviation. This ensures not only the quality of the product but also the safety of the operators, as these systems involve high temperatures, high vacuum, and high voltages.

Making the Right Choice for Your Goal

The decision to use vacuum processing is driven by an uncompromising need for material perfection. Your specific goal will determine which aspect of the process is most critical.

- If your primary focus is implant biocompatibility: Prioritize vacuum processing to eliminate the surface oxides and contaminants that can cause adverse biological reactions.

- If your primary focus is tool strength and longevity: Leverage vacuum heat treatments like quenching and tempering to maximize hardness and wear resistance without compromising material purity.

- If your primary focus is creating complex or novel components: Utilize vacuum sintering to manufacture advanced ceramic or metal parts with precisely engineered properties for cutting-edge applications.

Ultimately, leveraging a vacuum furnace is a strategic commitment to achieving the absolute material integrity demanded by modern medical technology.

Summary Table:

| Application | Key Benefit | Process Used |

|---|---|---|

| Biocompatible Implants | Eliminates oxidation, ensures purity | Annealing, Sintering |

| Surgical Tools | Enhances hardness and durability | Vacuum Carburizing, Quenching |

| Advanced Components | Fuses powders for high-density parts | Sintering |

Ready to elevate your medical manufacturing with precision vacuum furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored furnace technologies can ensure the purity and performance your medical devices demand!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics