In short, induction furnaces can melt nearly any metal. This includes common ferrous metals like iron and steel, non-ferrous metals such as aluminum and copper, precious metals like gold and platinum, and even highly reactive or specialty alloys under the right conditions.

The core principle is simple: an induction furnace is designed to melt materials that are electrically conductive. The technology uses electromagnetic fields to generate heat directly within the metal itself, making it a highly efficient process for metals but generally unsuitable for non-conductive materials like glass or ceramics.

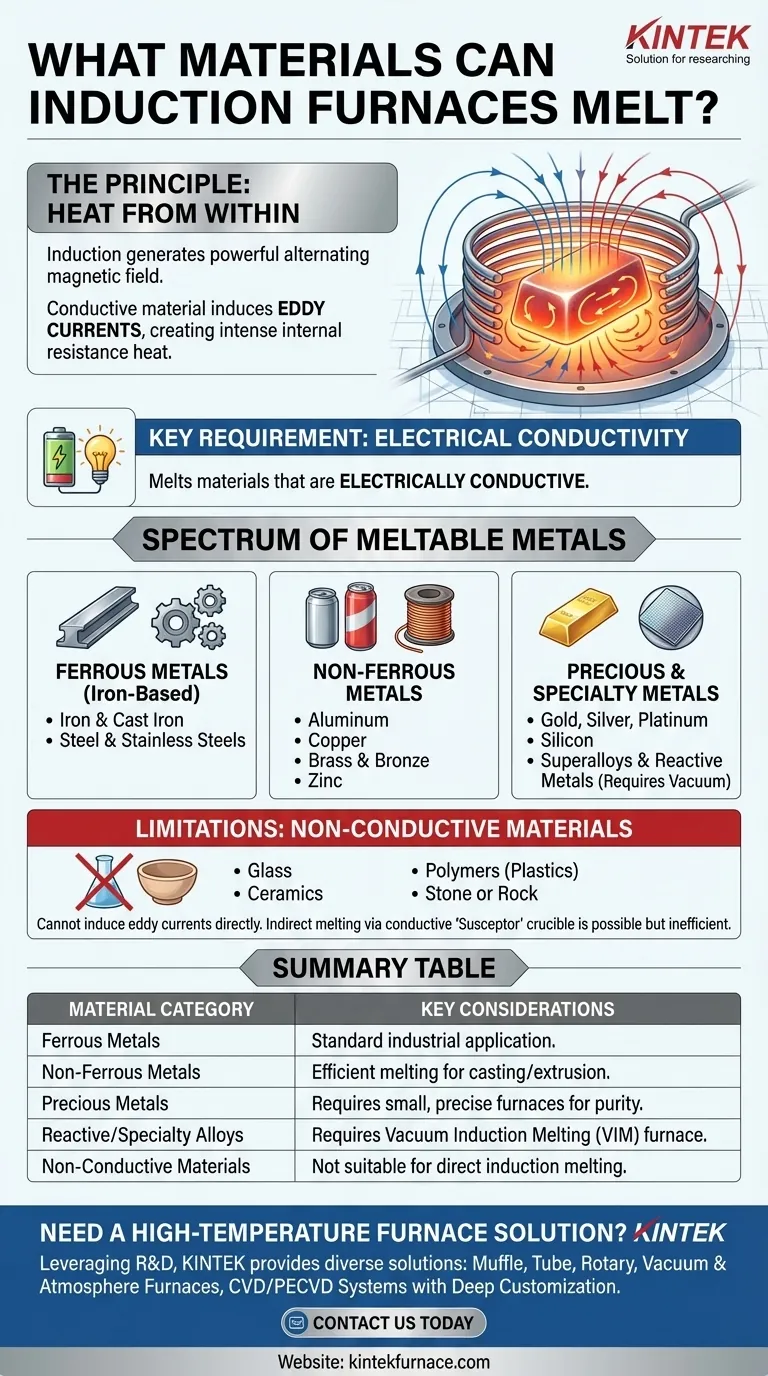

The Principle: Why Induction Excels with Metals

The effectiveness of an induction furnace is rooted in the physics of electromagnetism. Understanding this principle clarifies why it works on certain materials and not others.

How It Works: Heat from Within

An induction furnace does not use an external flame or heating element to melt material. Instead, it generates a powerful, alternating magnetic field.

When a conductive material like metal is placed inside this field, it induces strong electrical currents—known as eddy currents—to flow within the metal. The metal's natural resistance to this current flow generates intense, rapid heat, causing it to melt from the inside out.

The Key Requirement: Electrical Conductivity

This heating method is entirely dependent on the material's ability to conduct electricity. The better a material conducts electricity, the more effectively the magnetic field can induce the eddy currents needed for heating.

Metals are excellent electrical conductors, which is why they are the ideal charge for an induction furnace.

A Spectrum of Meltable Metals

The versatility of induction melting covers a vast range of industrial, commercial, and specialty applications.

Ferrous Metals (Iron-Based)

This is the most common application for large-scale induction furnaces. They are workhorses in foundries and steel mills for melting:

- Iron and Cast Iron

- Steel and Stainless Steels

Non-Ferrous Metals

Induction furnaces are also widely used for melting non-ferrous metals, which are critical for casting, extrusion, and manufacturing. Common examples include:

- Aluminum

- Copper

- Brass and Bronze

- Zinc

Precious and Specialty Metals

On a smaller but equally important scale, induction provides the precision and purity required for high-value materials. This includes:

- Gold, Silver, and Platinum group metals for jewelry and investment.

- Silicon for semiconductor and solar applications.

- Superalloys and Reactive Metals like zirconium, which require melting in a controlled vacuum induction furnace to prevent contamination.

Understanding the Trade-offs and Limitations

While powerful, an induction furnace is not a universal solution. Its effectiveness is defined by its operating principle, which creates clear limitations.

The Primary Limitation: Non-Conductive Materials

Materials that do not conduct electricity cannot be melted directly in an induction furnace. This includes:

- Glass

- Ceramics

- Polymers (Plastics)

- Stone or Rock

These materials do not allow for the formation of the eddy currents necessary for induction heating.

The "Susceptor" Workaround

In some niche applications, a non-conductive material can be melted indirectly. This is done by placing it inside a conductive crucible (often made of graphite or silicon carbide).

The furnace heats the crucible, and the crucible then radiates that heat to melt the material inside. However, this is an inefficient, secondary use of the technology.

The Importance of Furnace Design

Not all induction furnaces are the same. A furnace designed to melt 10 tons of steel is fundamentally different from one used to melt 10 ounces of platinum.

The size, power frequency, and design (e.g., coreless vs. channel furnace) are all engineered for specific materials and volumes. For highly reactive metals, a vacuum induction furnace is required to prevent oxygen and nitrogen from contaminating the melt.

Making the Right Choice for Your Application

Matching the material to the technology is the key to success.

- If your primary focus is industrial metal casting (iron, steel, aluminum): Induction is an ideal and highly efficient technology, with your main considerations being furnace capacity and power supply.

- If your primary focus is high-purity or reactive alloys (superalloys, specialty metals): You require a specialized vacuum induction furnace (VIM) to guarantee material purity by preventing atmospheric contamination.

- If your primary focus is precious metals (gold, platinum): A small, precise crucible-type induction furnace offers the clean melting and control needed to minimize material loss.

- If your primary focus is non-metals (glass, ceramics): An induction furnace is the wrong tool for direct melting; you should explore resistance furnaces, gas-fired kilns, or other heating technologies.

Ultimately, understanding that induction melting is fundamentally an electrical process is the key to leveraging its power for the right materials.

Summary Table:

| Material Category | Examples | Key Considerations |

|---|---|---|

| Ferrous Metals | Iron, Steel, Stainless Steel | Standard industrial application. |

| Non-Ferrous Metals | Aluminum, Copper, Brass, Zinc | Efficient melting for casting/extrusion. |

| Precious Metals | Gold, Silver, Platinum | Requires small, precise furnaces for purity. |

| Reactive/Specialty Alloys | Superalloys, Zirconium | Requires a Vacuum Induction Melting (VIM) furnace. |

| Non-Conductive Materials | Glass, Ceramics, Plastics | Not suitable for direct induction melting. |

Need a High-Temperature Furnace Solution Tailored to Your Specific Materials?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Whether your work involves common alloys, precious metals, or highly reactive materials requiring a vacuum environment, our expertise ensures optimal performance.

Our product line includes:

- Muffle Furnaces

- Tube Furnaces

- Rotary Furnaces

- Vacuum & Atmosphere Furnaces

- CVD/PECVD Systems

We complement this with strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Contact us today to discuss your application and get a solution engineered for your success!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification