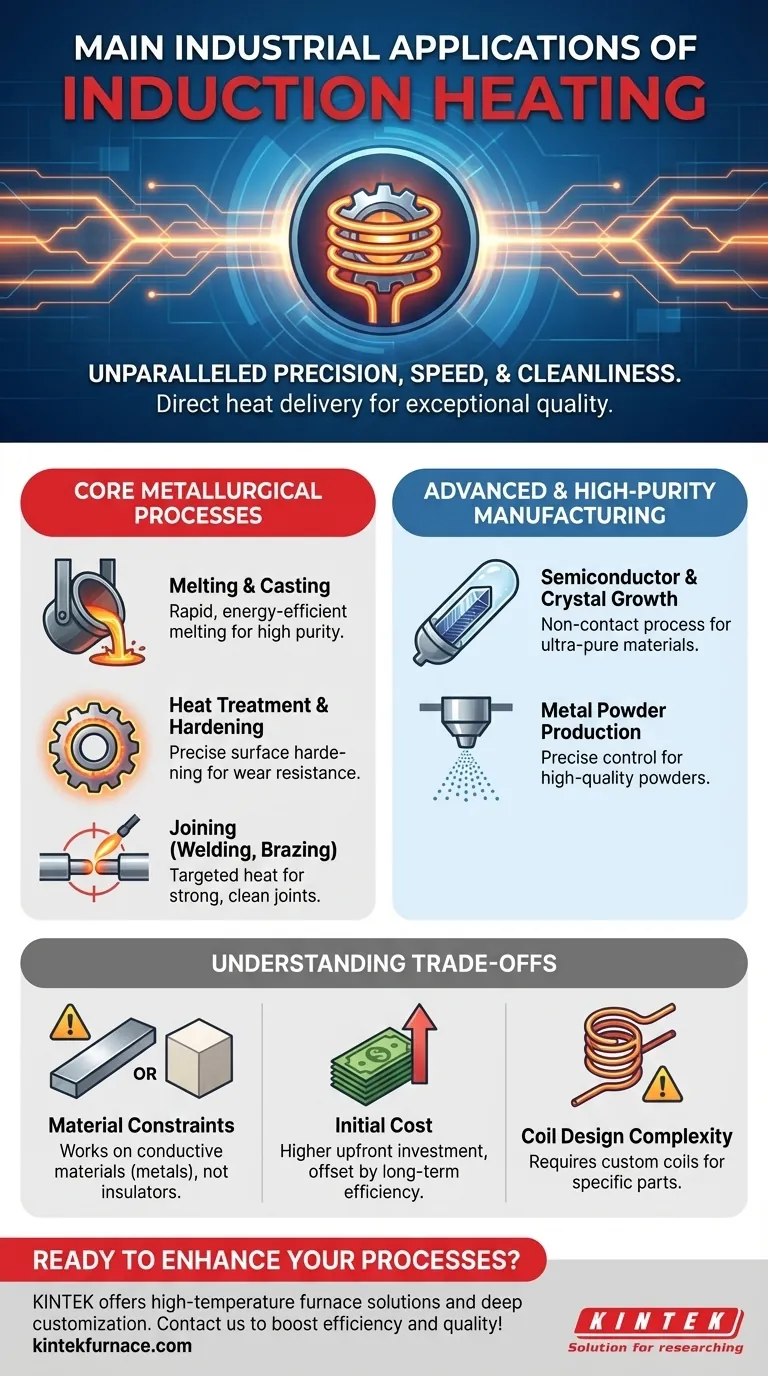

At its core, induction heating is a highly versatile tool used across a vast range of industries, from heavy metallurgy to advanced electronics. Its primary applications include the melting and casting of metals, precision heat treatment and surface hardening, high-purity material processing like semiconductor crystal growth, and the joining of components through welding, brazing, and soldering.

The true value of induction heating isn't just its ability to get things hot. It's the unparalleled precision, speed, and cleanliness with which it delivers that heat directly into a conductive material, enabling processes that demand exceptional quality and control.

Core Metallurgical Processes

The most widespread use of induction technology is in metallurgy, where its unique properties solve fundamental challenges in processing metals.

Melting and Casting

Induction furnaces are the standard in modern foundries and metal casting facilities. They are used for melting everything from steel and aluminum for automotive parts to gold and platinum in precious metal refining.

The process is valued for its speed and efficiency. Because the heat is generated directly within the metal charge, melting is rapid and energy losses are minimized compared to traditional fuel-fired furnaces. This also ensures high purity, as there are no combustion byproducts to contaminate the melt.

Heat Treatment and Hardening

Induction is ideal for surface hardening components like gears, axles, and bearings. The technology allows for precise, localized heating of only the surface layer of a part that needs to be hardened.

For example, you can harden the teeth of a gear without altering the ductility of its core. This creates a wear-resistant surface while maintaining the overall toughness of the component, a result that is difficult and inefficient to achieve with other methods.

Joining (Welding, Brazing, and Soldering)

When joining metal parts, controlling the heat-affected zone is critical to prevent distortion and weakening of the surrounding material. Induction allows for rapid, targeted heating of only the joint area.

This precision makes it a superior method for high-speed, automated brazing and soldering operations in industries from automotive to aerospace, ensuring strong, clean, and consistent joints.

Advanced and High-Purity Manufacturing

Beyond traditional metallurgy, induction heating is a critical enabler for high-technology products that depend on material purity and precise thermal control.

Semiconductor and Crystal Growth

In the semiconductor industry, material purity is paramount. Induction heating is used for zone refining and growing single crystals of silicon, as the process is non-contact.

The heating is induced from outside a sealed quartz chamber, meaning there is no physical heating element that could touch and contaminate the ultra-pure material. This cleanliness is essential for producing reliable electronic components.

Metal Powder Production

The rise of 3D printing and advanced coatings has created a demand for high-quality metal powders. Induction heating is a key component in processes like ultrasonic atomization.

In this method, a stream of molten metal, created efficiently in an induction furnace, is broken apart into fine droplets that solidify into a powder. The precise temperature control of induction is critical for achieving the desired particle size and quality.

Understanding the Trade-offs

While powerful, induction heating is not a universal solution. Understanding its limitations is key to applying it correctly.

Material Constraints

The foundational principle of induction heating requires the workpiece to be electrically conductive. It is highly effective on metals but cannot be used to directly heat most ceramics, plastics, or other insulators.

Initial Equipment Cost

The upfront investment for induction heating systems, including the power supply and custom-fabricated copper coils, can be significantly higher than for conventional resistance or gas furnaces. However, this cost is often offset by higher efficiency, faster cycle times, and reduced operational expenses over time.

Coil Design Complexity

The geometry of the induction coil is critical to the efficiency and uniformity of the heating process. Each specific part or application requires a carefully designed and tuned coil, making it less flexible for low-volume, high-mix production compared to a simple oven.

Making the Right Choice for Your Goal

Selecting induction heating depends entirely on the specific demands of your process.

- If your primary focus is high-volume production: The speed and repeatability of induction make it ideal for automated processes like surface hardening or brazing, where consistent quality over thousands of parts is essential.

- If your primary focus is material purity: The non-contact nature of induction is a requirement for applications in semiconductor manufacturing, medical implants, or aerospace alloys where any contamination is unacceptable.

- If your primary focus is energy efficiency: Induction is an excellent choice for melting, especially in scrap recycling, as it transfers energy directly into the metal with minimal waste heat.

Ultimately, induction heating’s value is unlocked by its unique ability to turn the workpiece into its own source of clean and precisely controlled heat.

Summary Table:

| Application Area | Key Uses | Benefits |

|---|---|---|

| Metallurgy | Melting, casting, heat treatment, hardening | High speed, energy efficiency, precise control |

| Joining | Welding, brazing, soldering | Localized heating, strong joints, minimal distortion |

| High-Purity Manufacturing | Semiconductor crystal growth, metal powder production | Non-contact process, material purity, contamination-free |

Ready to enhance your industrial processes with advanced induction heating solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can boost your efficiency and quality!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Induction Melting Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- What is the process of hot pressing? A Guide to Achieving Superior Material Density