In the automotive industry, Vacuum Hot Press (VHP) technology is a critical manufacturing process used to create high-performance components that are essential for modern vehicles. It plays a foundational role in producing everything from advanced battery electrodes for electric vehicles (EVs) to durable brake pads and lightweight structural alloys, directly impacting vehicle efficiency, safety, and performance.

The core function of Vacuum Hot Pressing is not just to form a part, but to fundamentally re-engineer a material's internal structure. By applying simultaneous heat and pressure in a controlled vacuum, it creates components with superior density and strength that are impossible to achieve with conventional methods.

How Vacuum Hot Pressing Works

The Core Principle: Heat, Pressure, and Vacuum

Vacuum Hot Pressing involves placing a material into a mold inside a vacuum chamber. The system then simultaneously applies intense heat and significant mechanical pressure.

The vacuum environment is the key differentiator. It prevents oxidation and eliminates trapped gases and impurities that would otherwise weaken the final component.

The Result: Denser, Stronger Components

This process forces the material's particles to bond together on a microscopic level, a process known as sintering or diffusion bonding.

The result is a finished part with significantly enhanced density, improved mechanical strength, and dramatically reduced porosity. This creates materials that are tougher, more durable, and more reliable under stress.

Critical Automotive Applications

Vacuum Hot Press technology is not a niche process; it is a driving force behind three of the most important trends in modern automotive engineering: electrification, safety, and efficiency.

Powering Electric Vehicles: Battery Components

For an EV's lithium-ion battery to be effective, its internal components must be flawless. VHP is used to sinter the cathode and anode materials.

This process creates a highly dense and uniform electrode structure, which is essential for maximizing energy storage, improving charge/discharge efficiency, and ensuring the long-term stability and safety of the battery pack.

Ensuring Safety: High-Performance Brakes

Brake pads and clutch discs must withstand extreme friction and heat without failing. VHP is used to produce these wear-resistant friction components.

By creating a uniformly dense material, the technology ensures that the brake pad wears evenly and predictably, providing consistent and reliable stopping power throughout its service life.

Improving Efficiency: Lightweight Structural Alloys

Reducing vehicle weight is critical for improving fuel economy in combustion vehicles and extending the range of EVs. VHP is used to fabricate components from lightweight aluminum and titanium alloys.

The technology enables the creation of complex, high-strength parts that are significantly lighter than their steel counterparts, contributing to better vehicle dynamics, performance, and overall efficiency.

Understanding the Trade-offs

While powerful, Vacuum Hot Pressing is a specialized process chosen for applications where material integrity is non-negotiable.

High Initial Investment

VHP equipment is complex and expensive, representing a significant capital expenditure. The machinery required to safely manage high temperatures, immense pressures, and a hard vacuum is highly specialized.

Slower Cycle Times

Compared to conventional mass-production techniques like stamping or casting, VHP is a slower, more deliberate batch process. The heating, pressing, and cooling cycles take time, making it best suited for critical, high-value components rather than low-cost, high-volume parts.

Requirement for Specialized Expertise

Operating and maintaining VHP systems requires highly skilled engineers and technicians. The precision required to control the process parameters means it is not a "plug-and-play" manufacturing solution.

Making the Right Choice for Your Goal

The decision to use Vacuum Hot Pressing hinges on whether the performance requirements of the component justify the process's precision and cost.

- If your primary focus is maximizing EV battery performance and longevity: VHP is the industry standard for sintering electrode materials to achieve superior energy density and stability.

- If your primary focus is enhancing vehicle safety and durability: VHP is the superior method for creating wear-resistant friction materials like brake pads that perform reliably under extreme conditions.

- If your primary focus is achieving aggressive lightweighting targets: VHP is a key enabler for fabricating high-strength structural components from advanced aluminum and titanium alloys.

Ultimately, Vacuum Hot Press technology is a foundational tool for building the safer, lighter, and more efficient vehicles of the future.

Summary Table:

| Application | Key Benefits |

|---|---|

| EV Battery Components | Maximizes energy density, improves charge/discharge efficiency, ensures safety and longevity |

| Brake Pads and Clutch Discs | Provides consistent stopping power, enhances wear resistance, improves durability |

| Lightweight Structural Alloys | Reduces vehicle weight, increases fuel economy and EV range, improves strength and performance |

Elevate your automotive manufacturing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored Vacuum Hot Press systems, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs in EV batteries, safety components, and lightweight alloys. Contact us today to discuss how we can enhance your production efficiency and component performance!

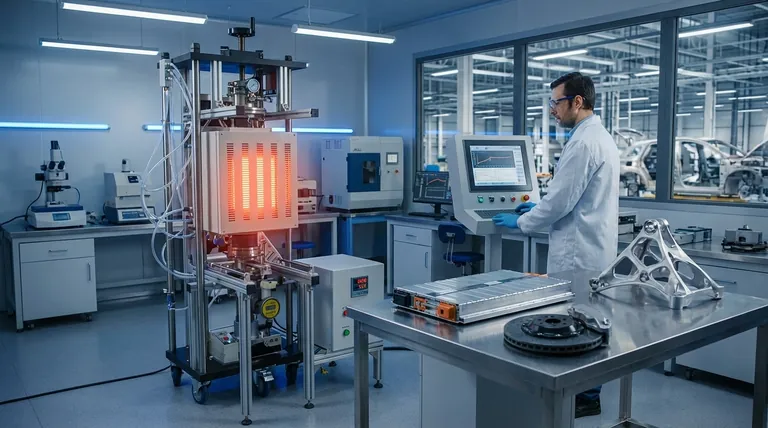

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction