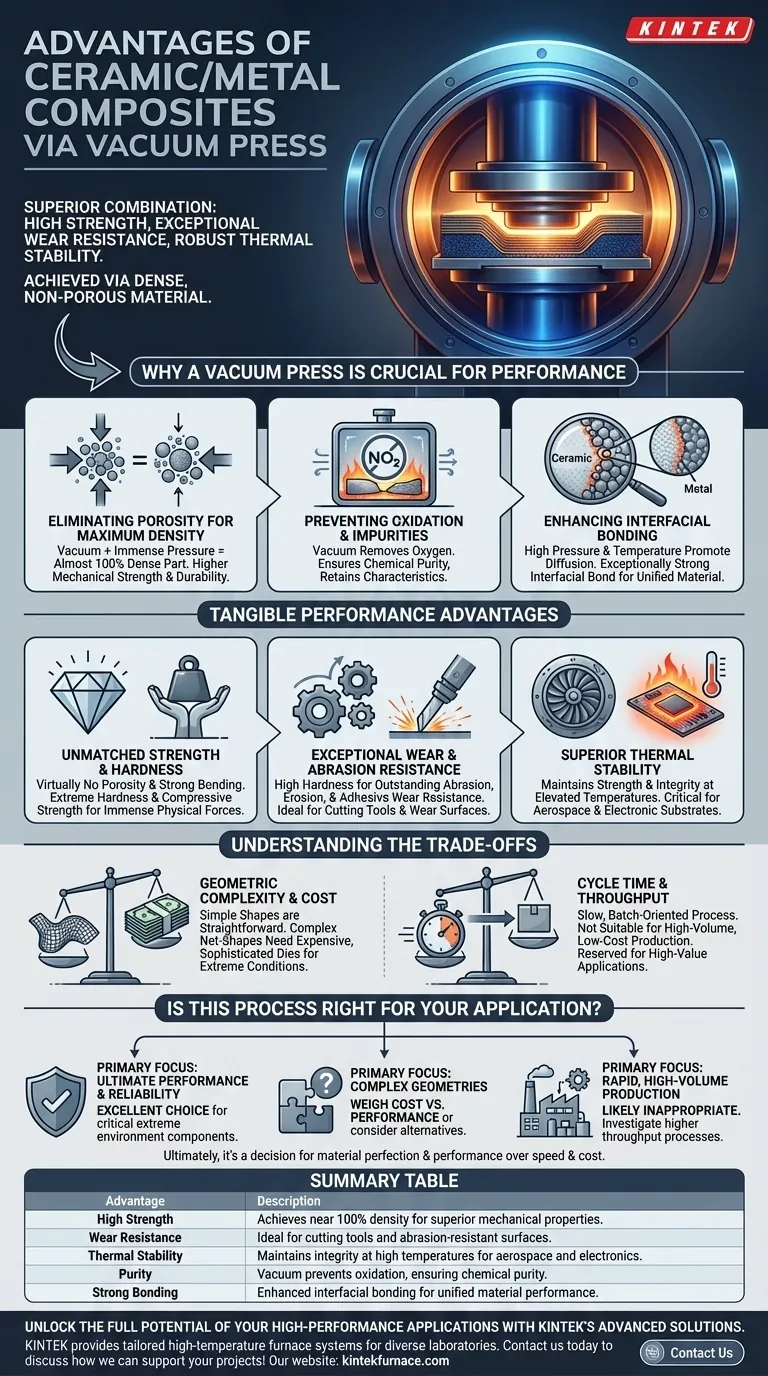

At its core, a ceramic/metal composite produced via a vacuum press offers a superior combination of high strength, exceptional wear resistance, and robust thermal stability. The vacuum hot pressing process is critical for achieving a dense, non-porous material, which is the source of these high-performance characteristics.

The true advantage is not just the properties of the ceramic and metal, but how the vacuum press process forges them into a nearly perfect, fully dense composite, free from the defects and impurities that compromise performance.

Why a Vacuum Press is Crucial for Performance

The manufacturing process is inseparable from the final material's properties. Using a vacuum hot press is a deliberate choice to create a material with minimal flaws and maximum performance.

Eliminating Porosity for Maximum Density

The combination of a vacuum and immense pressure physically compacts the ceramic and metal powders. This process squeezes out voids and air pockets, resulting in a final part that is almost 100% dense.

Porosity is a primary point of failure in materials, and its elimination directly translates to significantly higher mechanical strength and durability.

Preventing Oxidation and Impurities

Heating metals to the high temperatures required for sintering typically causes oxidation, which degrades their properties. The vacuum environment removes the oxygen, preventing these unwanted chemical reactions.

This ensures the final composite is chemically pure and that both the ceramic and metal components retain their intended characteristics.

Enhancing Interfacial Bonding

The high pressure and temperature applied during the process promote diffusion at the boundary between the ceramic and metal particles. This creates an exceptionally strong interfacial bond.

It is this robust bond that allows the composite to act as a single, unified material, effectively transferring loads between the hard ceramic and the tougher metal matrix.

The Tangible Performance Advantages

The near-perfect microstructure created by the vacuum press method directly leads to a set of highly desirable engineering properties.

Unmatched Strength and Hardness

With virtually no porosity and strong internal bonding, these composites exhibit extreme hardness and compressive strength. This makes them ideal for components that must withstand immense physical forces without deforming or fracturing.

Exceptional Wear and Abrasion Resistance

The high hardness, contributed primarily by the ceramic phase, provides outstanding resistance to abrasion, erosion, and adhesive wear. This is why these materials are used for high-end cutting tools and wear-resistant surfaces.

Superior Thermal Stability

These composites maintain their strength and structural integrity at elevated temperatures where most conventional metals would fail. This property is critical for demanding aerospace components like turbine parts and for electronic substrates that must dissipate heat effectively.

Understanding the Trade-offs

No single process is perfect for every situation. Understanding the limitations of vacuum hot pressing is key to making an informed decision.

Geometric Complexity and Cost

Simple shapes like plates, blocks, and cylinders are straightforward to manufacture with this method. However, producing complex, net-shape parts is a significant challenge.

It requires highly sophisticated and expensive pressing dies that can withstand the extreme temperature and pressure, making the tooling cost a major factor for intricate designs.

Cycle Time and Throughput

Vacuum hot pressing is an inherently slow, batch-oriented process. The time required for heating, pressing, and cooling limits throughput, making it unsuitable for high-volume, low-cost production.

This process is reserved for high-value applications where the exceptional performance justifies the longer manufacturing time and associated costs.

Is This Process Right for Your Application?

Choosing this material and process depends entirely on your project's specific priorities.

- If your primary focus is ultimate performance and reliability: Vacuum-pressed composites are an excellent choice for critical components in extreme environments where failure is not an option.

- If your primary focus is manufacturing complex geometries: You must carefully weigh the high cost of sophisticated dies against the performance gains or consider alternative processes.

- If your primary focus is rapid, high-volume production: This method is likely inappropriate, and you should investigate processes geared for higher throughput.

Ultimately, choosing a vacuum-pressed ceramic/metal composite is a decision to prioritize material perfection and performance over manufacturing speed and cost.

Summary Table:

| Advantage | Description |

|---|---|

| High Strength | Achieves near 100% density for superior mechanical properties. |

| Wear Resistance | Ideal for cutting tools and abrasion-resistant surfaces. |

| Thermal Stability | Maintains integrity at high temperatures for aerospace and electronics. |

| Purity | Vacuum prevents oxidation, ensuring chemical purity. |

| Strong Bonding | Enhanced interfacial bonding for unified material performance. |

Unlock the full potential of your high-performance applications with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering reliable ceramic/metal composites for critical uses. Ready to enhance your material performance? Contact us today to discuss how we can support your projects!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure