In essence, vacuum hot pressing is a high-performance manufacturing technique used to create exceptionally dense and pure materials that are difficult or impossible to produce using conventional methods. Its primary applications are in fabricating advanced ceramics, high-strength metal alloys, composites, and specialized electronic components for demanding industries like aerospace, medicine, and defense. This process uniquely combines heat, mechanical pressure, and a vacuum environment to simultaneously compact and sinter powdered materials into a solid, non-porous form.

The true value of vacuum hot pressing lies in its ability to produce materials with superior final properties. By eliminating atmospheric contamination and applying pressure during heating, it achieves near-total densification and controlled microstructures, resulting in components with exceptional strength, purity, and performance.

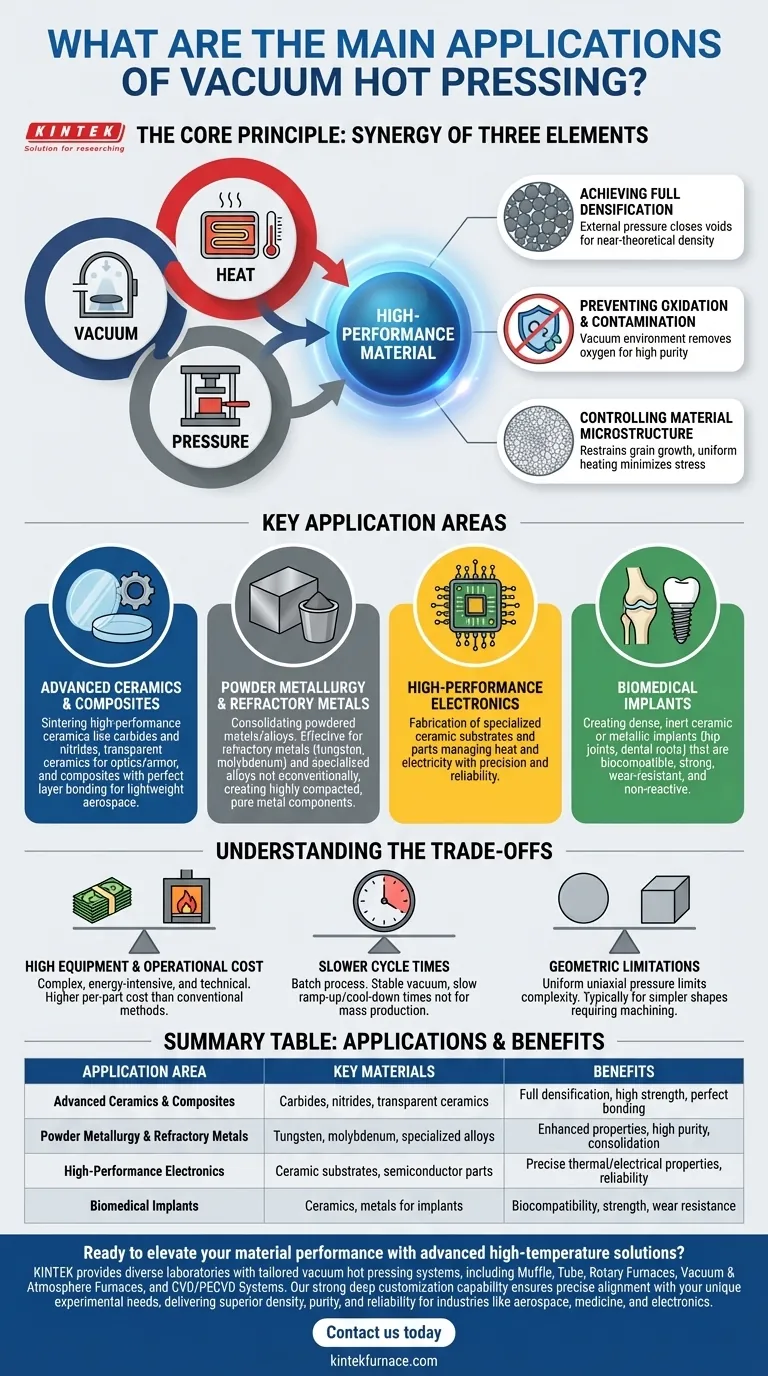

The Core Principle: Why Combine Vacuum, Heat, and Pressure?

Vacuum hot pressing is not simply a forming method; it is a material enhancement process. The synergy between its three core elements—vacuum, heat, and pressure—is what enables the creation of next-generation materials.

Achieving Full Densification

Traditional sintering relies only on heat to fuse particles, often leaving residual porosity that compromises a material's strength and other properties.

Vacuum hot pressing applies external pressure during the heating cycle. This mechanical force actively aids the consolidation of the powder, closing internal voids and driving the material to near-theoretical density. This is critical for applications requiring maximum durability and performance.

Preventing Oxidation and Contamination

Heating reactive materials like refractory metals or certain ceramics in air would cause immediate oxidation, fundamentally altering their properties and rendering them useless.

The vacuum environment removes oxygen and other atmospheric gases. This prevents oxidation and decarburization, ensuring the final product maintains its chemical purity. This "clean" processing environment is essential for manufacturing medical implants, electronic substrates, and high-purity metal components.

Controlling Material Microstructure

The final properties of a material are dictated by its internal crystal structure, or microstructure. Uncontrolled heating can lead to excessive grain growth, which often reduces material strength.

The combination of pressure and a controlled heating profile allows engineers to restrain unwanted crystal grain growth, especially in nanomaterials. Furthermore, slow, uniform heating in a vacuum minimizes thermal stress, reducing deformation and the need for costly post-processing machining.

Key Application Areas in Detail

The unique capabilities of vacuum hot pressing make it indispensable in sectors where material failure is not an option.

Advanced Ceramics and Composites

This is a primary application area. The process is used to sinter high-performance ceramics like carbides and nitrides, as well as to create fully dense, transparent ceramics for optical and armor applications. For composites, it ensures a perfect bond between different material layers, crucial for lightweight aerospace components.

Powder Metallurgy and Refractory Metals

Vacuum hot pressing is used to consolidate powdered metals and alloys into solid forms with enhanced properties. It is particularly effective for refractory metals (like tungsten and molybdenum) and for creating specialized alloys that cannot be melted and cast conventionally. The result is a highly compacted, pure metal component.

High-Performance Electronics

The manufacturing of certain electronic and semiconductor components requires materials with precisely defined thermal and electrical properties. Vacuum hot pressing enables the fabrication of specialized ceramic substrates and other parts that can manage heat and electricity with extreme reliability.

Biomedical Implants

Biocompatibility and strength are paramount for medical devices placed inside the human body. Vacuum hot pressing is used to create dense, inert ceramic or metallic implants, such as hip joints and dental roots, that are strong, wear-resistant, and will not react with the body.

Understanding the Trade-offs

While powerful, vacuum hot pressing is a specialized tool with specific limitations that make it unsuitable for every manufacturing need.

High Equipment and Operational Cost

Vacuum hot press furnaces are complex and expensive pieces of capital equipment. The process itself is energy-intensive and requires significant technical oversight, leading to higher per-part costs compared to conventional methods like casting or standard sintering.

Slower Cycle Times

The need to create a stable vacuum, slowly ramp up temperature, apply pressure, and cool down under controlled conditions makes the process inherently slow. It is a batch process, not suited for the high-throughput demands of mass production.

Geometric Limitations

The requirement to apply uniform uniaxial (single-direction) pressure limits the geometric complexity of the parts that can be produced. Typically, the process is used for simpler shapes like discs, blocks, or cylinders that will be machined into their final form.

Is Vacuum Hot Pressing Right for Your Application?

Choosing this process requires a clear understanding of your final component's performance requirements versus your production constraints.

- If your primary focus is maximum material density and purity: Vacuum hot pressing is the definitive choice for eliminating porosity and preventing contamination in sensitive materials.

- If your primary focus is producing near-net-shape advanced materials: This process excels at creating high-value components that require minimal post-processing machining, saving time and material waste.

- If your primary focus is cost-effective mass production: You should explore alternative methods like metal injection molding (MIM) or conventional press-and-sinter, as VHP is a specialized, high-cost process.

Ultimately, vacuum hot pressing is a strategic choice made when the performance and reliability of the material itself are the most critical factors for success.

Summary Table:

| Application Area | Key Materials | Benefits |

|---|---|---|

| Advanced Ceramics & Composites | Carbides, nitrides, transparent ceramics | Full densification, high strength, perfect bonding |

| Powder Metallurgy & Refractory Metals | Tungsten, molybdenum, specialized alloys | Enhanced properties, high purity, consolidation |

| High-Performance Electronics | Ceramic substrates, semiconductor parts | Precise thermal/electrical properties, reliability |

| Biomedical Implants | Ceramics, metals for implants | Biocompatibility, strength, wear resistance |

Ready to elevate your material performance with advanced high-temperature solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored vacuum hot pressing systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior density, purity, and reliability for industries like aerospace, medicine, and electronics. Contact us today to discuss how we can optimize your processes and achieve exceptional results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification