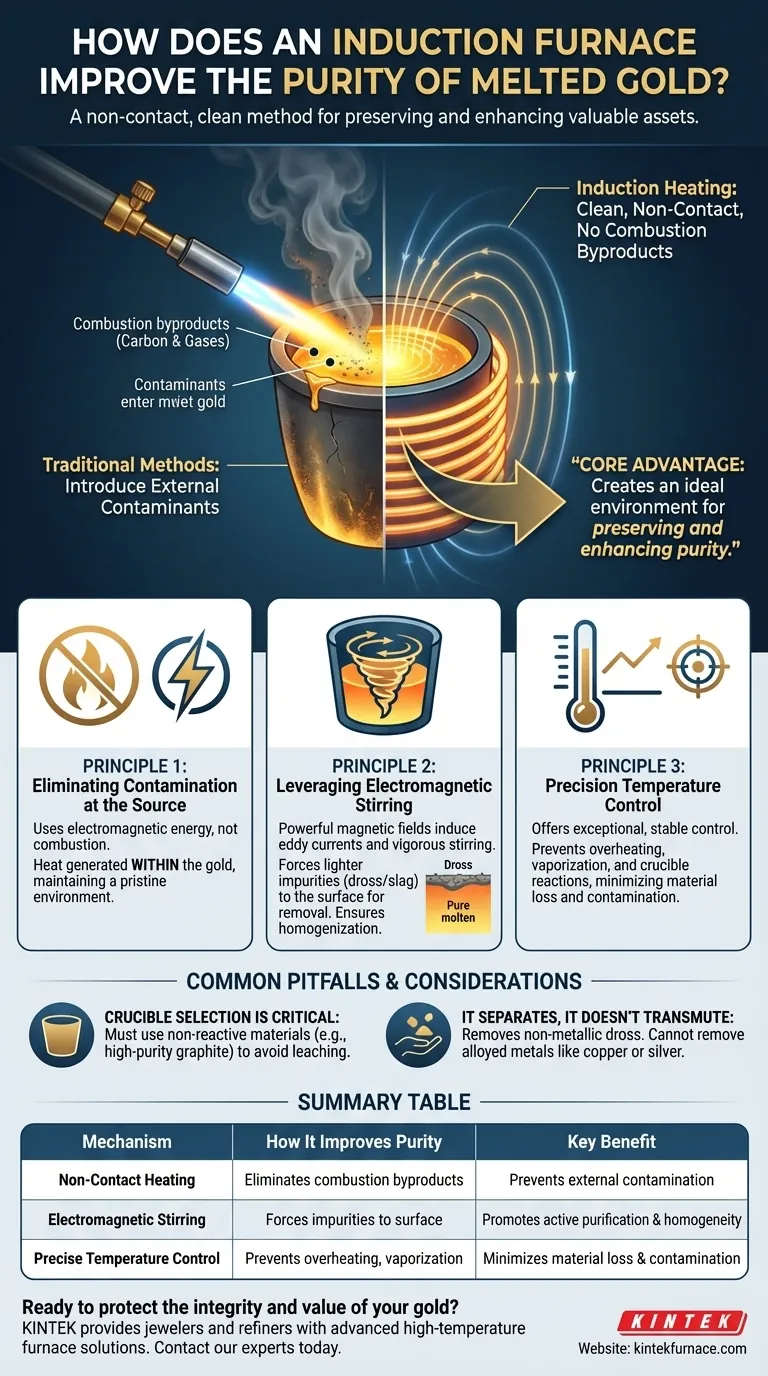

An induction furnace improves the purity of melted gold by using a clean, non-contact heating method that prevents contamination and actively helps separate impurities. Unlike flame-based techniques, induction heating uses a magnetic field to melt the metal, eliminating the introduction of byproducts from combustion. This process also provides precise temperature control and a natural stirring effect, which further enhances the final purity of the gold.

The core advantage of induction melting is not just that it melts gold, but that it creates an ideal environment for preserving and enhancing its purity. By eliminating external contaminants and promoting the separation of existing ones, it treats the metal as a valuable asset to be protected throughout the process.

The Core Mechanisms of Induction Purification

To understand how an induction furnace produces purer gold, we must look at three distinct physical principles that work in concert. These mechanisms are fundamentally different from traditional melting methods.

Principle 1: Eliminating Contamination at the Source

The most significant factor is the heating method itself. Traditional furnaces often rely on burning fossil fuels or using an open flame torch.

This combustion process releases contaminants, such as carbon and other gases, which can dissolve into the molten gold and reduce its fineness.

Induction heating is entirely different. It uses electromagnetic energy, creating no combustion byproducts. The heat is generated within the gold itself, ensuring the melting environment remains pristine and free from external pollutants.

Principle 2: Leveraging Electromagnetic Stirring

An induction coil generates powerful, fluctuating magnetic fields that induce electrical eddy currents within the gold. These currents are what generate the heat, but they also produce a secondary, crucial effect: electromagnetic stirring.

This natural, vigorous stirring of the molten metal is a key advantage. It ensures the entire melt is perfectly homogenized, preventing hot spots and creating a uniform temperature.

Most importantly, this stirring motion forces lighter, non-metallic impurities (dross and slag) to the surface, where they can be easily skimmed off before pouring. This is a form of active, in-process purification.

Principle 3: Precision Temperature Control

Induction systems offer exceptionally precise and stable temperature control. This prevents the gold from overheating, which is a common issue with less controllable flame-based methods.

Overheating can cause two problems. First, it can cause some of the gold to vaporize, leading to direct material loss and lower yields. Second, excessive temperatures can cause the molten gold to react with the crucible material, introducing new impurities into the melt.

By maintaining the gold at the perfect melting temperature, an induction furnace minimizes both material loss and the risk of crucible contamination.

Common Pitfalls and Considerations

While highly effective, an induction furnace is not a magic solution. Its effectiveness depends on proper operation and understanding its limitations.

Crucible Selection is Critical

The crucible is the container that holds the molten gold. Using the wrong material can completely negate the purity benefits of induction.

The crucible must be made of a non-reactive material, such as high-purity graphite or ceramic. A poor-quality or incorrect type of crucible can leach impurities into the melt, contaminating the very gold you are trying to purify.

It Separates, It Doesn't Transmute

An induction furnace excels at maintaining purity and separating non-metallic dross. The electromagnetic stirring helps slag float to the surface for removal.

However, it cannot remove other metals that are alloyed with the gold, such as copper or silver. Separating these dissolved metals requires a completely different chemical process, such as the Miller process or Wohlwill process used in large-scale refining.

Making the Right Choice for Your Goal

Your choice of melting technology should align directly with your objectives for quality, volume, and purity.

- If your primary focus is maximum purity and process control (refining, investment bars): An induction furnace is the definitive choice for preventing contamination and maximizing yield.

- If your primary focus is creating consistent, high-quality alloys (jewelry manufacturing): The homogeneity from induction's natural stirring is a critical advantage that ensures uniform karat value and color.

- If your primary focus is occasional, small-scale work on a tight budget: A traditional torch may be adequate, but you must accept the inherent risks of lower purity and material loss.

Ultimately, choosing an induction furnace is a decision to prioritize the integrity and value of the final product.

Summary Table:

| Mechanism | How It Improves Purity | Key Benefit |

|---|---|---|

| Non-Contact Heating | Eliminates combustion byproducts from flames. | Prevents external contamination. |

| Electromagnetic Stirring | Forces impurities (dross/slag) to the surface for removal. | Promotes active purification and homogeneity. |

| Precise Temperature Control | Prevents overheating, vaporization, and crucible reactions. | Minimizes material loss and contamination. |

Ready to protect the integrity and value of your gold?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides jewelers and refiners with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique purity and production requirements.

Contact our experts today to find the perfect induction furnace solution for your application.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys