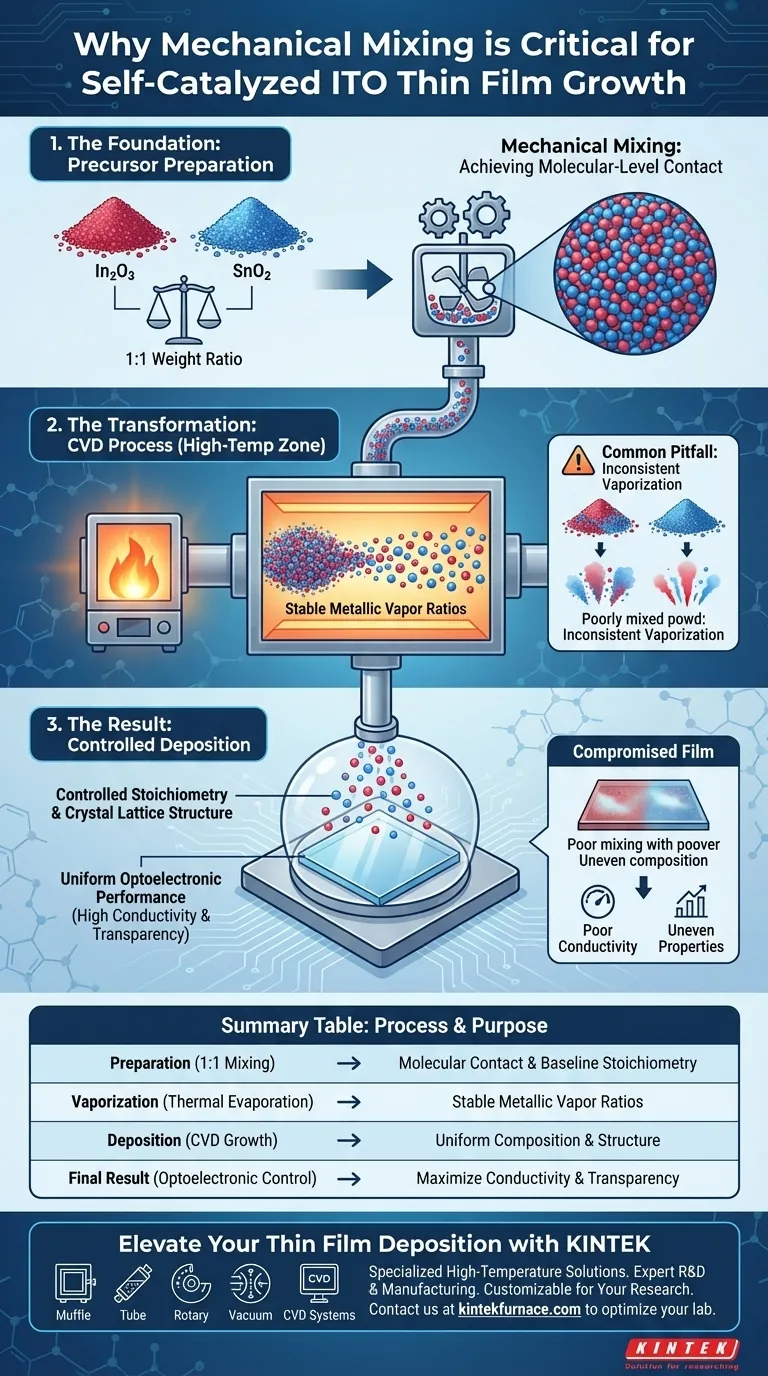

The mechanical mixing of precursor powders is the critical control step that dictates the consistency of Indium Tin Oxide (ITO) thin film growth. By physically blending high-purity Indium Oxide (In2O3) and Tin Oxide (SnO2) at a specific 1:1 weight ratio, you ensure the materials achieve molecular-level contact before the Chemical Vapor Deposition (CVD) process begins. This physical uniformity is required to stabilize the metallic vapor ratios generated in the high-temperature zone, directly securing the film's final composition.

Without thorough mechanical mixing, the precursor materials cannot generate a predictable or uniform vapor phase. This step provides the necessary foundation to control the film's stoichiometric ratio, which is the primary driver of its final optoelectronic performance.

The Mechanics of Precursor Preparation

Achieving Molecular Contact

The primary objective of mechanical mixing is not simply to place two powders in the same container, but to force them into molecular-level contact.

In the initial stage of preparation, the In2O3 and SnO2 powders must be integrated so thoroughly that they behave as a single, cohesive source material.

This intimate contact is the prerequisite for the chemical reactions that will follow in the CVD system.

The Role of the 1:1 Weight Ratio

The standard protocol involves mixing these high-purity powders in a precise 1:1 weight ratio.

This specific balance creates a baseline for the material load entering the system.

It prevents one component from dominating the source volume, ensuring both Indium and Tin are available for vaporization in correct proportions.

From Powder to Vapor: The CVD Process

Controlling Metallic Vapor Generation

Once the precursors enter the high-temperature zone of the CVD system, the quality of the mechanical mix determines the behavior of the vapor.

A uniform mixture ensures that the metallic vapor component ratios are generated consistently.

If the powders are well-mixed, the system produces a steady stream of Indium and Tin vapors rather than fluctuating bursts of isolated elements.

Influencing Stoichiometry

The vapor ratio generated in the heat zone directly dictates the final stoichiometric ratio of the deposited thin film.

Stoichiometry refers to the quantitative relationship between the elements in the final crystal lattice.

By controlling the powder mix, you effectively lock in the chemical formula of the growing film.

Defining Optoelectronic Performance

The ultimate goal of this process is to maximize the film's utility in electronic applications.

The stoichiometric ratio achieved through proper mixing directly influences the film's optoelectronic performance.

This includes critical properties such as electrical conductivity and optical transparency.

Common Pitfalls to Avoid

Inconsistent Vaporization

If the mechanical mixing is insufficient, the precursors will not have molecular-level contact.

This leads to "hot spots" in the vapor generation, where the ratio of Indium to Tin fluctuates unpredictably during deposition.

Compromised Film Quality

A lack of foundation in the precursor stage cannot be fixed later in the CVD process.

If the metallic vapor ratios are unstable, the resulting thin film will likely exhibit poor or uneven optoelectronic properties.

Ensuring Quality in Your CVD Process

To maximize the quality of your ITO thin films, view mechanical mixing as a high-precision manufacturing step rather than a simple prep task.

- If your primary focus is Compositional Accuracy: Ensure a strict 1:1 weight ratio of high-purity powders to establish a reliable stoichiometric baseline.

- If your primary focus is Film Uniformity: Prioritize the duration and intensity of the mechanical mixing to guarantee absolute molecular-level contact before heating.

By rigorous mechanical mixing, you transform two separate powders into a single, unified source capable of growing high-performance thin films.

Summary Table:

| Process Phase | Action | Purpose for ITO Growth |

|---|---|---|

| Preparation | 1:1 Weight Ratio Mixing | Establishes molecular-level contact and baseline stoichiometry. |

| Vaporization | Thermal Evaporation | Generates stable metallic vapor ratios of Indium and Tin. |

| Deposition | CVD Growth | Ensures uniform film composition and crystal lattice structure. |

| Final Result | Optoelectronic Control | Maximizes electrical conductivity and optical transparency. |

Elevate Your Thin Film Deposition with KINTEK

Precise precursor preparation requires high-performance equipment to yield consistent results. At KINTEK, we specialize in providing the foundation for advanced material science. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your unique research and production needs.

Whether you are focusing on the self-catalyzed growth of ITO or advanced semiconductor research, our high-temperature solutions ensure the thermal stability and control necessary for superior optoelectronic performance.

Ready to optimize your lab's efficiency? Contact us today to discuss your custom furnace requirements.

Visual Guide

References

- Muchammad Yunus, Azianty Saroni. Effect of Deposition Temperature on The Structural and Crystallinity Properties of Self-Catalyzed Growth Indium Tin Oxide (ITO) Thin Film Using CVD Technique. DOI: 10.24191/srj.v22i2.23000

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- Why is the addition of silver nanoparticles critical for Ag2Se films? Unlock High Thermoelectric Performance

- Why is precise temperature control in an aging oven critical for ZK61 alloys? Master the 175°C Pre-aging Threshold

- Why is a high-precision mass flow controller essential for long-term restart performance testing of catalysts?

- What are the advantages of using electron bombardment heating systems for Niobium? Achieve Industrial Fidelity

- What occurs during the recrystallization stage of annealing? Restore Ductility and Reset Microstructure

- What preparatory questions should be addressed before converting to electrically heated processes? Ensure a Smooth Transition to Electric Heating

- Why is hydrothermal synthesis utilized for the production of ZIF-8? Control Nanocrystal Purity and Uniformity

- What is the primary function of a laboratory drying oven in cotton stalk pyrolysis? Ensure Data Integrity