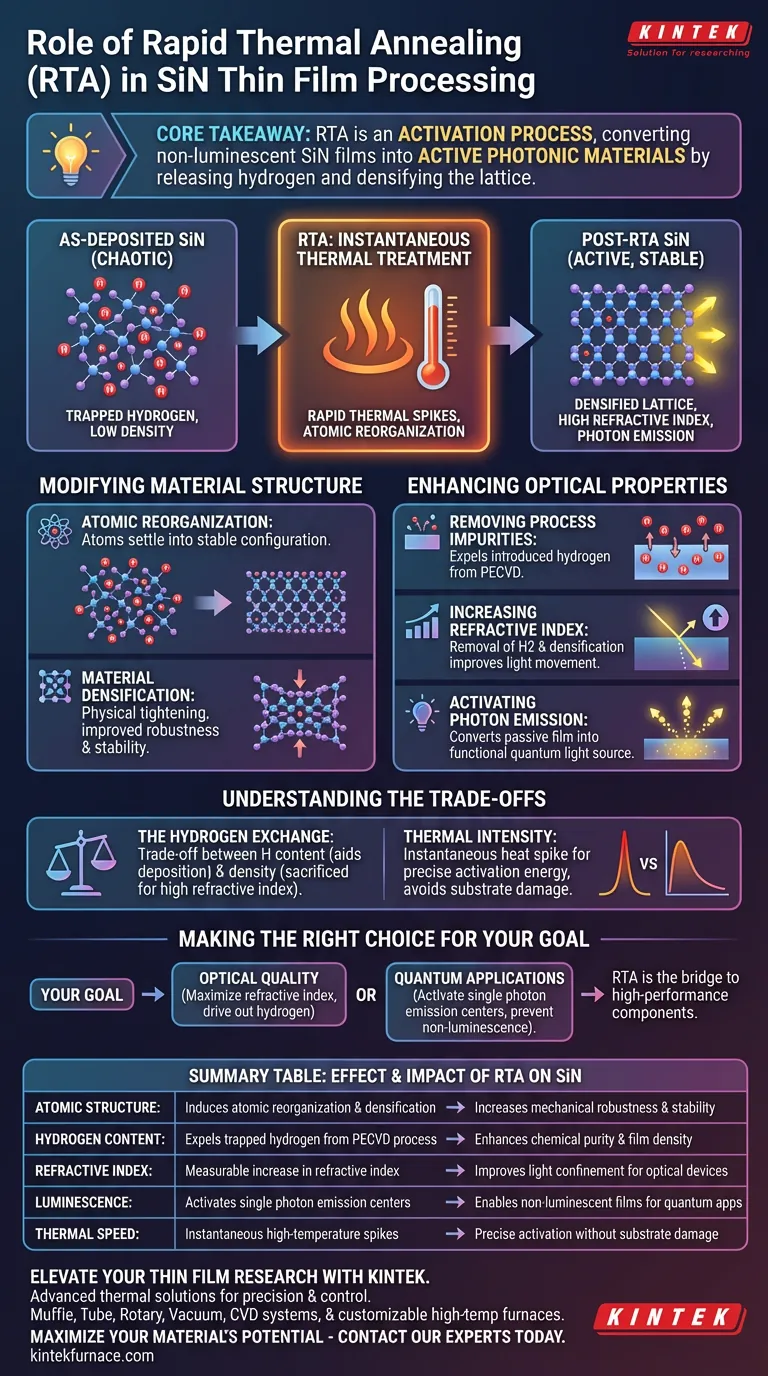

A Rapid Thermal Annealing (RTA) system serves as a decisive post-processing tool that applies high-temperature, instantaneous thermal treatment to Silicon Nitride (SiN) thin films. Its primary function is to transform the "as-deposited" material by driving atomic reorganization and altering the film's chemical composition immediately after deposition.

Core Takeaway: RTA is not merely a hardening step; it is an activation process that converts non-luminescent SiN films into active photonic materials. By releasing trapped hydrogen and densifying the lattice, it stabilizes the film for single photon emission.

Modifying the Material Structure

Atomic Reorganization

The deposition process often leaves the material in a chaotic or metastable state. RTA uses rapid thermal spikes to induce atomic reorganization, allowing the atoms to settle into a more thermodynamically stable configuration.

Material Densification

As the atomic structure aligns, the film undergoes significant densification. This physical tightening of the lattice is crucial for improving the mechanical robustness and environmental stability of the thin film.

Enhancing Optical Properties

Removing Process Impurities

Films created via Plasma Enhanced Chemical Vapor Deposition (PECVD) inherently contain hydrogen. RTA is essential for breaking the weak bonds of this introduced hydrogen and expelling it from the material.

Increasing Refractive Index

The removal of hydrogen and the subsequent densification directly impact how light moves through the material. This process results in a measurable increase in the refractive index, a key metric for high-performance optical devices.

Activating Photon Emission

For quantum applications, the "as-deposited" film is often non-luminescent. The thermal shock provided by the RTA system activates single photon emission centers, converting the passive film into a functional source of quantum light.

Understanding the Trade-offs

The Hydrogen Exchange

There is a direct trade-off between hydrogen content and film density. While hydrogen aids the initial chemical deposition (PECVD), it must be sacrificed via RTA to achieve the high density and refractive index required for advanced optics.

Thermal Intensity

Unlike gradual furnace annealing, RTA relies on instantaneous heat application. This intensity is required to achieve the specific activation energy for photon centers, but it requires precise control to avoid damaging the underlying substrate.

Making the Right Choice for Your Goal

To maximize the utility of your Silicon Nitride films, consider your specific application requirements:

- If your primary focus is Optical Quality: Utilize RTA to drive out hydrogen and maximize the refractive index for superior light confinement.

- If your primary focus is Quantum Applications: You must employ RTA to activate the specific defects required for stable single photon emission, as untreated films will remain non-luminescent.

The RTA process is the bridge between a raw deposited coating and a functional, high-performance optical component.

Summary Table:

| Feature | Effect of RTA on SiN Thin Films | Impact on Performance |

|---|---|---|

| Atomic Structure | Induces atomic reorganization and densification | Increases mechanical robustness and stability |

| Hydrogen Content | Expels trapped hydrogen from PECVD process | Enhances chemical purity and film density |

| Refractive Index | Measurable increase in refractive index | Improves light confinement for optical devices |

| Luminescence | Activates single photon emission centers | Enables non-luminescent films for quantum apps |

| Thermal Speed | Instantaneous high-temperature spikes | Precise activation without substrate damage |

Elevate Your Thin Film Research with KINTEK

Ready to transform your SiN thin films into high-performance photonic components? KINTEK’s advanced thermal solutions provide the precision and control necessary for critical material activation. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable high-temperature lab furnaces designed to meet your unique processing requirements.

Maximize your material's potential—contact our experts today to find the perfect RTA or furnace system for your laboratory.

Visual Guide

References

- Zachariah O. Martin, Vladimir M. Shalaev. Single-photon emitters in PECVD-grown silicon nitride films: from material growth to photophysical properties. DOI: 10.1515/nanoph-2024-0506

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is shrinkage in the context of high-temperature materials? Master Dimensional Control for Stronger Parts

- Why is a blank control experiment without a sample required? Ensure Accuracy in Oxide Scale Measurement

- Why is Copper (Cu) introduced as a flux in AlN single crystal growth? Enhance Source Stability and Yield

- What is the function of an electric arc furnace in the preparation of aluminum-silicon model alloys? Expert Insights

- What are the advantages of using a microwave reaction system? Rapid & Uniform Synthesis of Doped Hydroxyapatite

- What is the function of a heated tundish in a metal powder production system? Optimize Flow and Thermal Consistency

- What role does quartz sand filler play in a crystal growth furnace? Enhance Thermal Symmetry and Yield

- What are the advantages of using a nitrate salt bath furnace? Superior Quenching for Sorbitic Steel Wire