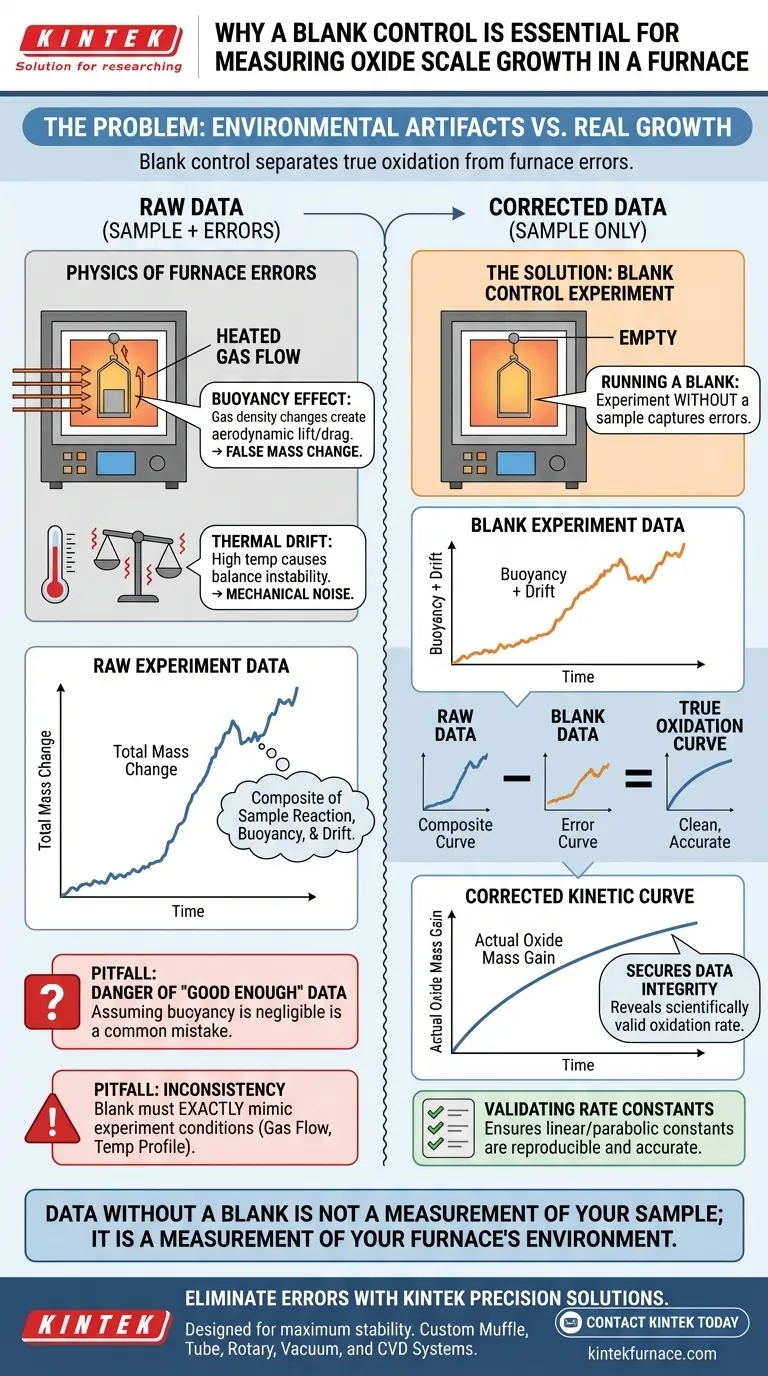

Conducting a blank control experiment is the only way to distinguish actual oxide growth from environmental artifacts. In high-temperature furnace environments, factors such as gas density changes and mechanical drift create false weight readings that mimic or mask real chemical changes. Running a blank cycle—an experiment without a sample—allows you to quantify and subtract these errors, ensuring that your data reflects only the true oxidation kinetics of your material.

The blank control acts as a critical baseline, filtering out the buoyancy effects of heated gas flow and the thermal drift of the balance to reveal the scientifically valid oxidation rate of the sample.

The Physics of Furnace Measurement Errors

To understand why a blank is necessary, you must first understand the invisible forces acting on your measurement system inside the furnace.

The Buoyancy Effect

When gases are heated, their density changes significantly. As gas flows through the furnace, these density variations create aerodynamic forces—lift or drag—on the sample holder.

This is known as the buoyancy effect. It registers as a mass change on the balance even though no chemical reaction has occurred. Without a blank control, you might mistakenly interpret this lift as a loss or gain in sample mass.

Systemic Temperature Drift

Thermogravimetric balances are highly sensitive instruments. As the furnace temperature ramps up, the balance mechanism itself experiences thermal drift.

This inherent instability in the balance system adds noise to your raw data. A blank experiment captures this specific mechanical behavior so it can be mathematically removed later.

Securing Data Integrity

The ultimate goal of measuring oxide scales is to derive accurate kinetic models. The blank control is the mathematical key to this accuracy.

Retrieving True Oxidation Curves

Raw data from a furnace is a composite of three things: the sample reaction, the buoyancy effect, and the system drift.

By subtracting the blank values (buoyancy + drift) from the raw data, you isolate the true oxidation kinetic curve. This corrected curve represents the actual mass gain of the oxide scale alone.

Validating Rate Constants

Researchers rely on linear and parabolic rate constants to predict how a material will behave over time.

If you calculate these constants using raw data, they will be skewed by the environmental artifacts mentioned above. Correcting with a blank ensures these constants are scientifically valid and reproducible.

Common Pitfalls in Methodology

While the concept of a blank control is simple, failing to execute it correctly can compromise your results.

The Danger of "Good Enough" Data

It is a common mistake to assume that buoyancy effects are negligible in heavy samples. In reality, even small buoyancy errors can significantly distort the slope of a kinetic curve, leading to incorrect conclusions about the oxidation mechanism.

Consistency is Critical

The blank experiment must mimic the actual experiment exactly. You must use the exact same gas flow rates and temperature profiles as your sample run. If the conditions differ, the subtraction will be inaccurate, introducing new errors rather than removing old ones.

Making the Right Choice for Your Goal

To ensure your oxide growth measurements are defensible, apply the following approach to your experimental design.

- If your primary focus is high-precision kinetics: Run a fresh blank control for every distinct temperature profile to account for specific buoyancy behaviors.

- If your primary focus is determining rate constants: Ensure you subtract the blank data from the raw data before calculating any linear or parabolic constants to avoid mathematical distortion.

Data without a blank control is not a measurement of your sample; it is a measurement of your furnace's environment.

Summary Table:

| Factor | Impact on Measurement | How Blank Control Corrects It |

|---|---|---|

| Buoyancy Effect | Gas density changes create false mass gain/loss. | Quantifies aerodynamic lift for mathematical subtraction. |

| Thermal Drift | Temperature fluctuations cause balance instability. | Captures mechanical noise to isolate real chemical changes. |

| Data Accuracy | Raw data includes environmental artifacts. | Filters out systemic errors to reveal true oxidation curves. |

| Rate Constants | Skewed linear/parabolic results. | Validates constants by basing them on corrected kinetic data. |

Eliminate Measurement Errors with KINTEK Precision Solutions

Don't let buoyancy and thermal drift compromise your research integrity. KINTEK provides industry-leading thermal processing equipment designed for maximum stability and scientific precision.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique experimental needs. Whether you are measuring oxide growth or developing new materials, our systems provide the controlled environment necessary for defensible data.

Ready to upgrade your lab's performance? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- M.S. Archana, S. Ningshen. Initial Stage Oxidation of 304HCu Stainless Steel in Oxygen Environment. DOI: 10.1007/s12666-024-03478-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a laboratory furnace and why is it important? Unlock Precision Heating for Your Lab

- What type of furnaces are commonly used for sintering? Choose the Right Furnace for Your Process

- What is the significance of the 220 °C annealing process? Unlock High-Purity Anti-Perovskite Thin Film Synthesis

- What role do high-precision laboratory ovens play in assessing the energy potential of MSW? Enhancing Biomass Accuracy

- How does a high-precision laboratory oven ensure the performance of large-scale halide perovskite catalyst plates?

- What is the role of a ventilated oven in the drying pretreatment of uranium tailings? Ensure Safety and Flowability

- What is the role of vacuum pressure impregnation equipment in Fe3O4 synthesis? Master Magnetic Wood Fiber Engineering

- What are the advantages of supersonic inert gas cooling in DGCC? Transform Heat Treatment and Microstructure Control