The primary technical advantage of Directional Gas Cooling Casting (DGCC) is the fundamental shift from passive radiative cooling to active convective cooling. While the traditional Bridgman method relies on low-efficiency radiation, DGCC utilizes supersonic inert gas flows to significantly accelerate heat extraction. This introduction of highly efficient convective heat transfer allows for precise thermal management, even in the most geometrically complex sections of a casting.

By replacing passive radiation with active supersonic convection, DGCC overcomes the cooling limitations inherent in large, complex castings. This results in significantly finer microstructures and improved mechanical properties, particularly in wide sections where traditional methods struggle.

The Physics of Heat Transfer

Limitations of the Bridgman Method

The traditional Bridgman method relies primarily on radiation cooling.

This mechanism is inherently low-efficiency, particularly when trying to extract heat rapidly from solidifying metal.

Because radiation relies on line-of-sight and surface area, it often fails to provide uniform cooling rates across complex geometries.

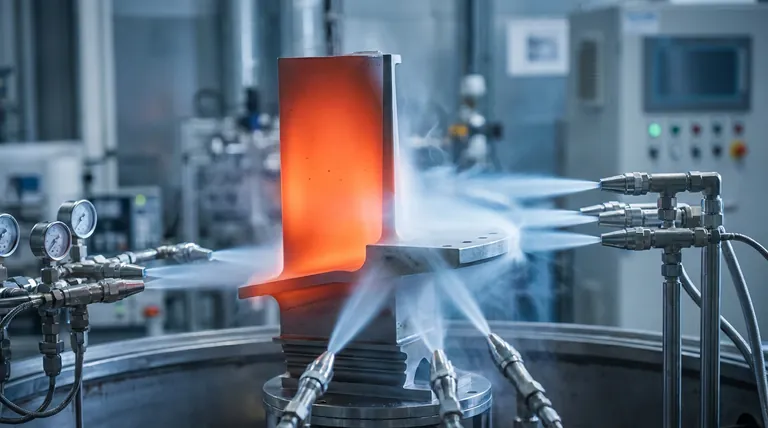

The Power of Supersonic Convection

DGCC addresses this inefficiency by introducing supersonic inert gas flows.

This changes the primary heat transfer mechanism to convection, which is far more efficient at removing heat energy.

The velocity of the gas flow ensures that heat is stripped away from the casting surface much faster than radiation alone could achieve.

Impact on Microstructure and Geometry

Solving the "Platform" Problem

One of the most critical advantages of DGCC is its performance on wide sections like blade platforms.

In traditional casting, these extended areas are difficult to cool uniformly because radiation is insufficient to penetrate the thermal mass effectively.

Supersonic gas flows can be directed to these specific areas, ensuring that wide, heavy sections cool at a rate consistent with the rest of the casting.

Refining Dendrite Spacing

The enhanced cooling capability of DGCC has a direct, measurable impact on the material's microstructure.

It can refine dendrite spacing to approximately 100 μm, specifically in the difficult platform areas.

This refinement is critical because finer dendrite spacing typically correlates with reduced chemical segregation and better fatigue resistance.

Uniformity in Large-Scale Castings

For large-scale single-crystal castings, maintaining structural uniformity is the ultimate challenge.

DGCC improves microstructural uniformity across the entire part, eliminating the variations often seen between thin and thick sections in Bridgman castings.

This leads to superior overall mechanical properties, making the component more reliable under stress.

Understanding the Trade-offs

Complexity vs. Necessity

While DGCC offers superior cooling, it introduces significantly higher process complexity compared to the Bridgman method.

The Bridgman method is passive and established; DGCC requires precise control of high-velocity gas flows.

Implementing supersonic flow systems adds variables to the casting environment that must be strictly managed to prevent turbulence-induced defects.

Suitability for Standard Parts

The advanced cooling of DGCC is a solution specifically designed for limitations in complex castings.

For simple, small, or uniform geometries, the traditional Bridgman method may still suffice.

Engineers must evaluate if the geometry of the part actually requires the high-efficiency convection of DGCC, or if radiation cooling is adequate for the specific design.

Making the Right Choice for Your Goal

To determine if DGCC is the correct approach for your manufacturing process, consider the specific requirements of your component geometry and performance standards.

- If your primary focus is large, complex geometries: DGCC is essential for ensuring microstructural uniformity in wide sections like blade platforms.

- If your primary focus is maximizing mechanical properties: The ability of DGCC to refine dendrite spacing to ~100 μm makes it the superior choice for high-performance single-crystal castings.

By leveraging supersonic convective cooling, you can achieve a level of microstructural control that is simply unattainable through traditional radiation-based methods.

Summary Table:

| Feature | Traditional Bridgman Method | Directional Gas Cooling Casting (DGCC) |

|---|---|---|

| Heat Transfer Mechanism | Passive Radiation (Low Efficiency) | Active Supersonic Convection (High Efficiency) |

| Cooling Control | Limited by geometry and line-of-sight | Highly precise and directable |

| Wide Section Performance | Poor; prone to non-uniformity | Excellent; solves 'platform' cooling issues |

| Dendrite Spacing | Coarser microstructure | Refined to ~100 μm in complex areas |

| Best Application | Simple, small, or uniform geometries | Large, complex single-crystal castings |

Optimize Your Casting Precision with KINTEK

Are you struggling with microstructural non-uniformity in complex geometries? KINTEK provides industry-leading high-temperature lab solutions designed to tackle the most demanding thermal challenges.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your unique research or production needs. Whether you are refining dendrite spacing or developing large-scale single-crystal components, our team is ready to provide the specialized equipment you need for success.

Contact KINTEK Today for a Professional Consultation

Visual Guide

References

- Dariusz Szeliga, Artur Wiechczyński. Directional Solidification of Single-Crystal Blades in Industrial Conditions Using the Developed Gas Cooling Casting Method. DOI: 10.1007/s11661-024-07391-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

People Also Ask

- Why is annealing considered a core process in perovskite solar cell manufacturing? Unlock Peak Efficiency

- Why does the use of a forced-air drying oven often lead to increased particle size? Avoid Silica Agglomeration

- How does a laboratory furnace affect chemical bonding in hybrid composites? Unlock Superior Material Strength

- Why is precise temperature control essential for carbon material synthesis? Achieve Superior Purity and Microstructure

- Why is a stainless steel high-pressure autoclave essential for starch hydrogenation? Unlock Peak Reaction Efficiency

- Why is a glove box necessary for aluminum foil pre-lithiation? Ensure Purity in Anode Development

- What is the role of a rapid thermal processing furnace in CdO/CdS/ZnO fabrication? Achieve High-Quality Heterojunctions

- What role does industrial heating equipment play in the manufacturing process of 55Si2 spring steel during winding?