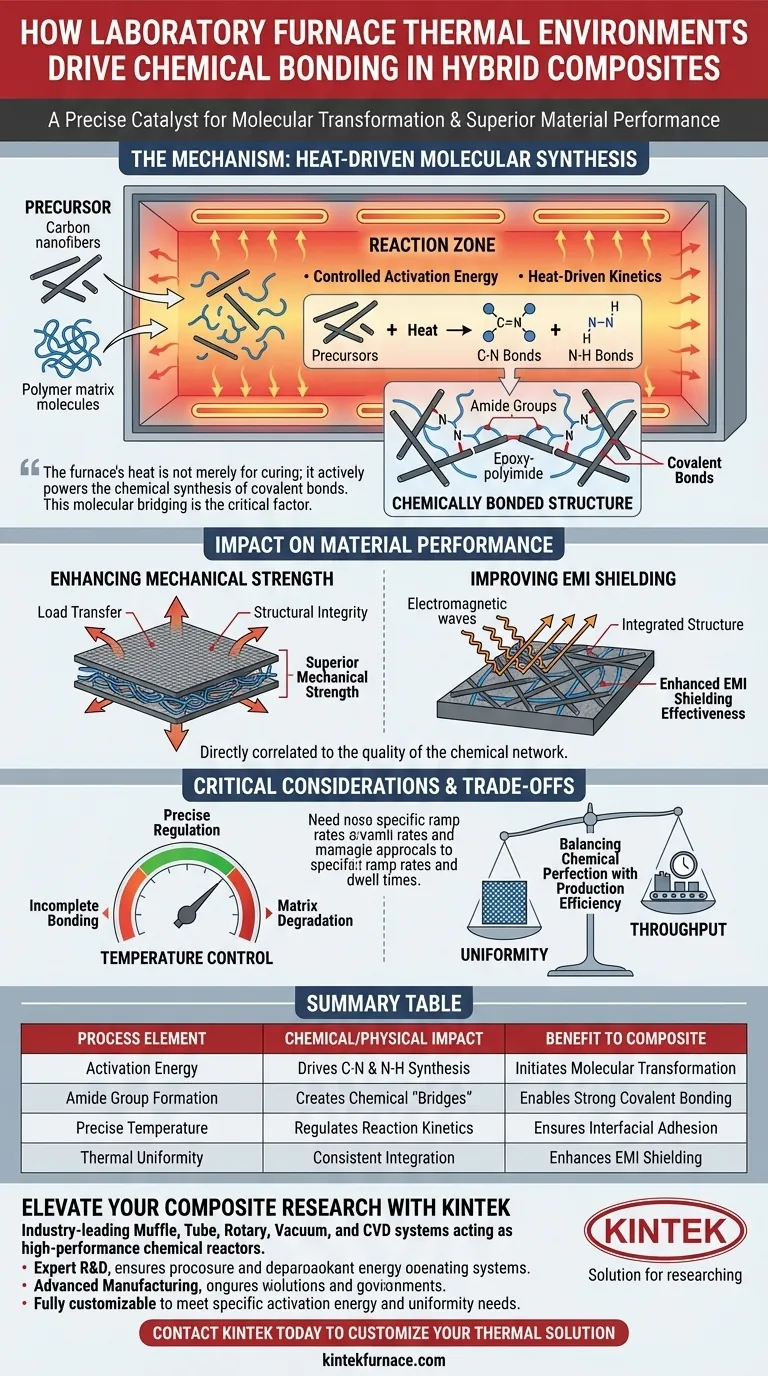

The thermal environment of a laboratory furnace acts as a precise catalyst for molecular transformation. By providing a controlled application of heat, the furnace drives the formation of specific functional groups—specifically C-N bonds, N-H bonds, and amide groups. This energy input is the mechanism that allows modified carbon nanofibers to chemically link with polymer matrices like epoxy-polyimide.

The furnace’s heat is not merely for curing; it actively powers the chemical synthesis of covalent bonds. This molecular bridging is the critical factor that transforms separate components into a unified hybrid composite with superior mechanical and electromagnetic properties.

The Mechanism of Heat-Driven Bonding

Facilitating Molecular Formation

The primary role of the furnace is to provide the activation energy required for chemical synthesis.

Without this controlled heat, the precursor materials would remain inert relative to one another. The thermal environment drives the reaction kinetics necessary to create functional groups—specifically Carbon-Nitrogen (C-N) and Nitrogen-Hydrogen (N-H) bonds.

Creating the Chemical Bridge

The formation of these groups results in the creation of amide groups.

These amide groups serve as the chemical "bridge" between the reinforcement material and the matrix. Specifically, they facilitate strong covalent bonding between modified carbon nanofibers and the epoxy-polyimide matrix. This transforms the interface from a simple physical mixture into a chemically bonded structure.

Impact on Material Performance

Enhancing Mechanical Strength

The covalent bonds formed in the furnace significantly increase the structural integrity of the composite.

By chemically locking the nanofibers to the polymer matrix, load transfer is improved. This results in a material with much higher mechanical strength compared to composites where the fibers are merely suspended in the matrix.

Improving EMI Shielding

Beyond strength, this bonding process enhances the material's functional properties.

The integrated structure created by the furnace improves the material's ability to block electromagnetic interference. The EMI shielding effectiveness is directly correlated to the quality of the chemical network established during the heating process.

Critical Considerations and Trade-offs

The Precision of Temperature Control

While the furnace facilitates bonding, the process relies heavily on precise temperature regulation.

If the thermal environment varies, the formation of C-N and N-H bonds may be incomplete, leading to weak interfacial adhesion. Conversely, excessive heat could degrade the polymer matrix before the bonds fully form.

Uniformity vs. Throughput

Achieving a "controlled thermal environment" often requires slower ramp rates or specific dwell times to ensure uniformity throughout the matrix.

This focus on chemical perfection can increase processing time. Operators must balance the need for maximizing covalent bond density with the efficiency of the production cycle.

Making the Right Choice for Your Goal

To leverage the thermal environment effectively for hybrid composites, consider your specific performance targets:

- If your primary focus is mechanical durability: Ensure the furnace profile is optimized to maximize the yield of amide group formation, as these covalent bonds dictate the load-bearing capacity of the interface.

- If your primary focus is EMI shielding: Prioritize thermal uniformity to ensure the carbon nanofibers are chemically integrated evenly across the entire matrix, preventing gaps in protection.

The furnace is not just a heater; it is a chemical reactor that dictates the ultimate performance of your hybrid composite.

Summary Table:

| Process Element | Chemical/Physical Impact | Benefit to Composite |

|---|---|---|

| Activation Energy | Drives C-N and N-H bond synthesis | Initiates molecular transformation |

| Amide Group Formation | Creates chemical "bridges" | Enables strong covalent bonding |

| Precise Temperature | Regulates reaction kinetics | Ensures interfacial adhesion |

| Thermal Uniformity | Consistent fiber-matrix integration | Enhances EMI shielding effectiveness |

Elevate Your Composite Research with KINTEK

Precise chemical bonding requires uncompromising thermal control. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed to act as high-performance chemical reactors for your most demanding hybrid composite projects.

Backed by expert R&D and advanced manufacturing, our laboratory furnaces are fully customizable to meet your specific activation energy and temperature uniformity needs. Whether you are optimizing amide group density or enhancing EMI shielding, KINTEK delivers the precision your materials deserve.

Contact KINTEK Today to Customize Your Thermal Solution

Visual Guide

References

- Teguh Endah Saraswati, Wijang Wisnu Raharjo. Enhanced Performance of Epoxy Resin-Polyimide Hybrid Composites with Aminated Carbon Nanofibers Filler. DOI: 10.26554/sti.2025.10.1.152-164

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are advanced materials and composites? Unlock Superior Performance for Your Innovations

- What is the purpose of equipping the condensation section of a sodium heat pipe with a specialized insulation cover?

- Why is high-precision constant temperature heating equipment required when preparing 17-4 PH stainless steel composite?

- Why is precise control of carrier gas flow rates required for hydrochar activation? Optimize Carbon Yield & Purity

- What are the objectives of melt stirring and insulation treatment during the Al-5Er-Ti master alloy preparation process?

- What is the function of a laboratory cryofurnace during Co3O2BO3 experiments? Precise Phase Transition Control

- What is the function of a Laboratory Forced Air Drying Oven in fruit waste pretreatment? Ensure Superior Carbon Yields

- Why is achieving process pressure within defined time important? Boost Efficiency, Quality, and Safety