Industrial heating equipment serves as a vital prerequisite for the successful winding of 55Si2 spring steel. By raising the temperature of steel rods prior to the winding phase, this equipment fundamentally alters the material's physical state to allow for smooth, accurate formation without structural damage.

The primary function of industrial heating in this context is to increase material plasticity and reduce deformation resistance. This ensures the steel can be wound into precise spiral shapes while minimizing internal stress and preventing surface micro-cracks.

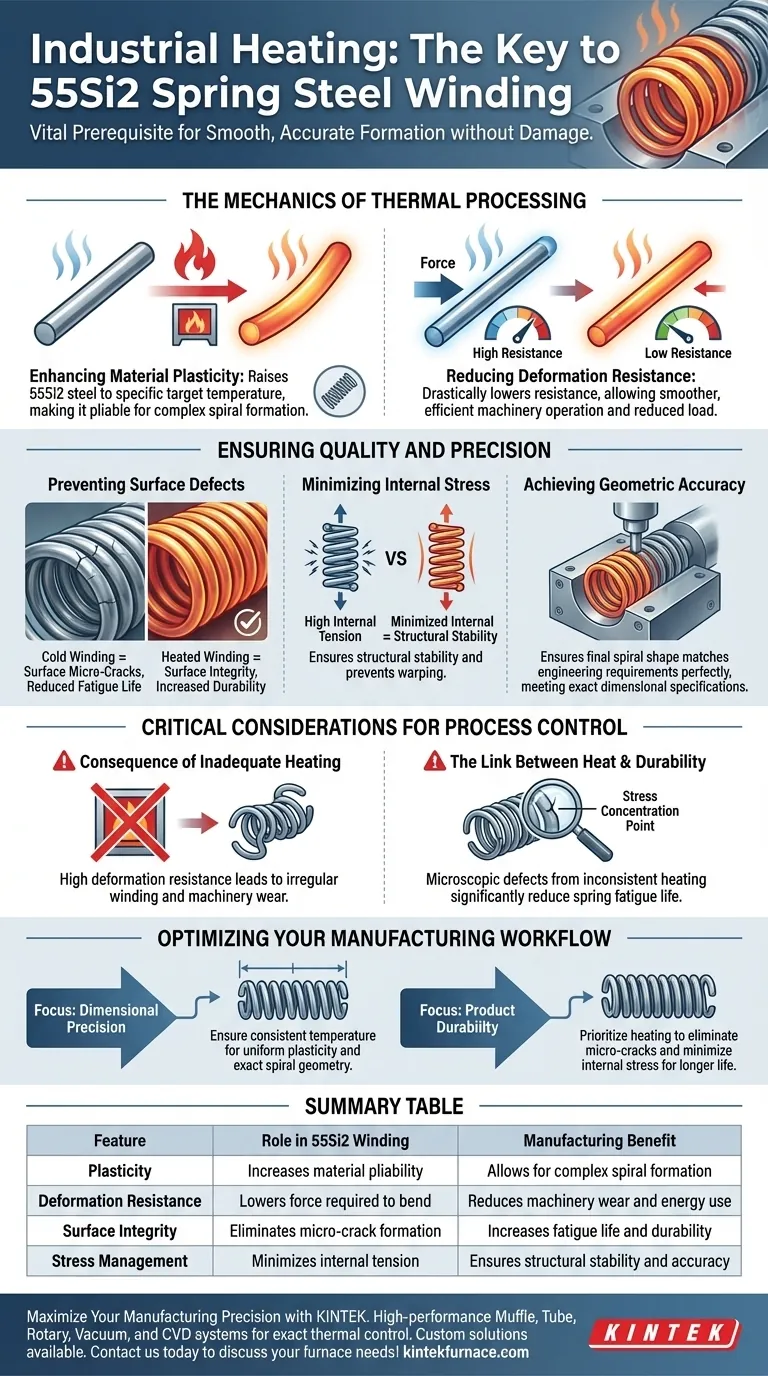

The Mechanics of Thermal Processing

Enhancing Material Plasticity

The core challenge in winding 55Si2 spring steel is its natural rigidity. Industrial heating equipment addresses this by raising the steel rods to a specific target temperature.

This thermal application significantly increases the plasticity of the material. By making the steel more pliable, manufacturers can manipulate the rod into complex spiral forms that would be impossible or damaging to achieve at room temperature.

Reducing Deformation Resistance

When steel is cold, it resists changing shape. This resistance requires immense force to overcome, which can strain winding machinery.

Heating the rods drastically lowers deformation resistance. This allows the winding equipment to operate more smoothly and efficiently, reducing the mechanical load required to bend the steel rod into its required curvature.

Ensuring Quality and Precision

Preventing Surface Defects

One of the most critical roles of heating is the preservation of the steel's surface integrity. Cold winding often leads to fracturing on the material's surface.

Proper heating mitigates the risk of surface micro-cracks. By ensuring the material flows rather than tears during bending, the heating process protects the structural longevity of the final spring.

Minimizing Internal Stress

Bending metal introduces internal tension that can lead to premature failure or warping later in the product's life.

Heating the 55Si2 steel helps to minimize this internal stress during the formation process. A spring wound from properly heated steel retains its structural stability better than one forced into shape while cold.

Achieving Geometric Accuracy

Precision is non-negotiable in spring manufacturing. The final product must meet exact dimensional specifications.

The increased plasticity provided by the heating equipment ensures the steel conforms strictly to the winding machinery's path. This results in precise geometric dimensions, ensuring the final spiral shape matches the engineering requirements perfectly.

Critical Considerations for Process Control

The Consequence of Inadequate Heating

While the reference highlights the benefits of heating, the inverse highlights a critical risk. If the equipment fails to reach the specific temperature required, deformation resistance remains high.

This can lead to irregular winding, increased wear on machinery, and a final product that deviates from the required geometric tolerances.

The Link Between Heat and Durability

The reduction of surface micro-cracks is not merely cosmetic; it is a structural necessity.

If the heating process is bypassed or inconsistent, the resulting micro-cracks become stress concentration points. These microscopic defects significantly reduce the fatigue life of the spring, leading to potential failure under load.

Optimizing Your Manufacturing Workflow

Industrial heating is not just a preparatory step; it is a quality assurance mechanism. Use the following guide to align your process with your goals:

- If your primary focus is Dimensional Precision: Ensure your heating equipment maintains a consistent temperature to guarantee uniform plasticity and exact spiral geometry.

- If your primary focus is Product Durability: Prioritize the heating phase to eliminate surface micro-cracks and minimize internal stress, which are the leading causes of early spring failure.

Mastering the thermal preparation of 55Si2 steel is the single most effective way to ensure both manufacturing efficiency and product reliability.

Summary Table:

| Feature | Role in 55Si2 Winding | Manufacturing Benefit |

|---|---|---|

| Plasticity | Increases material pliability | Allows for complex spiral formation |

| Deformation Resistance | Lowers force required to bend | Reduces machinery wear and energy use |

| Surface Integrity | Eliminates micro-crack formation | Increases fatigue life and durability |

| Stress Management | Minimizes internal tension | Ensures structural stability and accuracy |

Maximize Your Manufacturing Precision with KINTEK

Don’t let inadequate heating compromise the integrity of your 55Si2 spring steel. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to deliver the exact thermal control your process demands.

Whether you need a standard solution or a system fully customized for your unique lab or industrial requirements, our engineers are ready to help you achieve superior geometric accuracy and product durability.

Ready to upgrade your thermal processing? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Enhancing the mechanical and functional characteristics of structural spring steel through the advancement of heat treatment technologies. DOI: 10.21595/vp.2025.24992

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the main purpose of annealing? A Guide to Controlling Material Properties

- What is the objective of performing an annealing treatment? Enhance Plasticity and Stress Relief for Al-Composites

- Why is SF6 gas utilized as the primary inhibitor in AS-ALD on ZrO2? Master Defect-Based Passivation Strategy

- What are the benefits of ESR for carbonitride distribution in H13 steel? Enhance Your Material's Isotropic Properties

- Which furnace is used for sintering? Find the Right High-Temperature Solution for Your Materials

- How does a displacement measurement device ensure data validity? Mastering Iron Ore Softening Shrinkage Accuracy

- Why is the use of a vacuum oven mandatory for drying Ti3C2Tx MXene precursors? Protect Your Advanced 2D Materials

- What are the core technical advantages of an industrial microwave sintering system? Gain Speed and Material Integrity