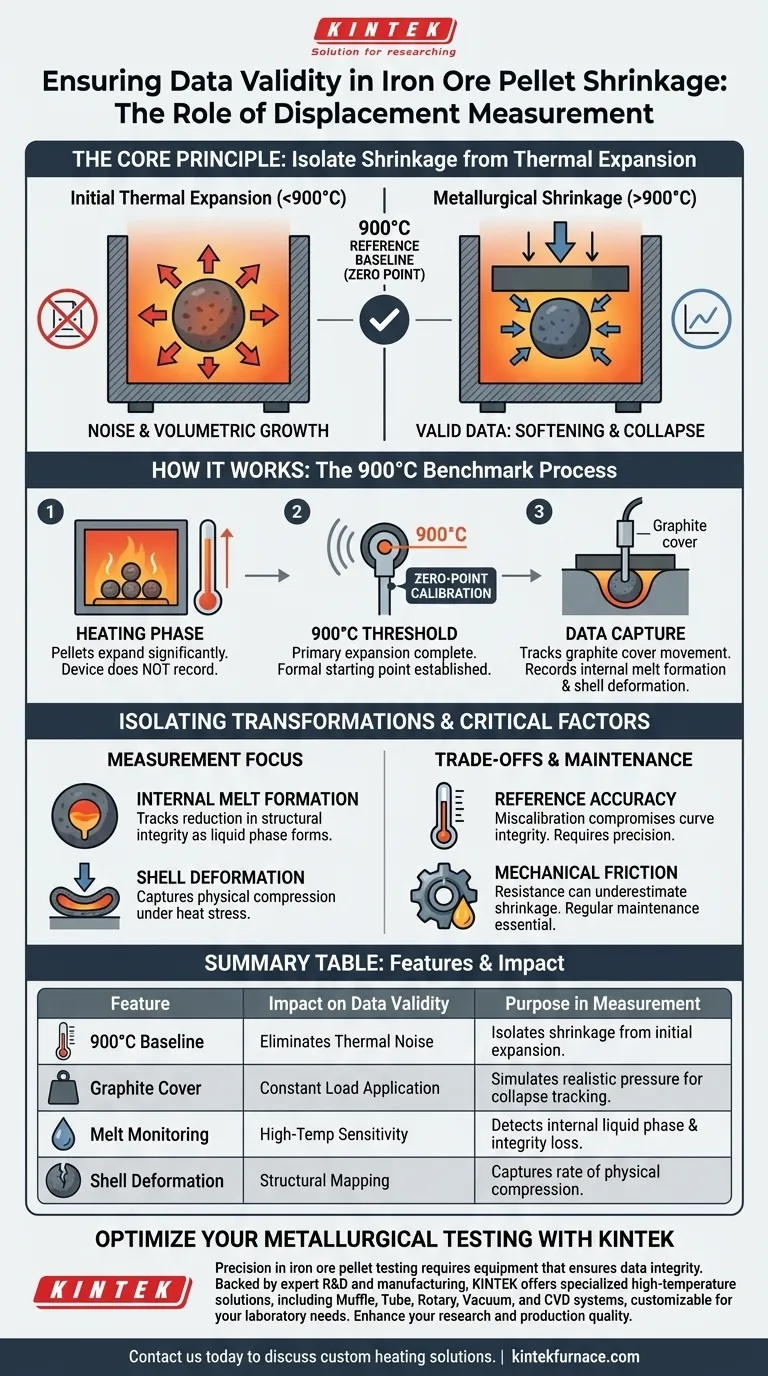

A displacement measurement device ensures data validity by isolating metallurgical shrinkage from initial thermal expansion through the use of a 900°C reference baseline. By recording the position of a graphite cover only after the iron ore pellets have reached this critical temperature, the system eliminates the "noise" of volumetric growth that occurs during the early heating stages. This specific calibration ensures that the resulting data reflects only the physical softening and structural collapse of the pellet.

The core validity of shrinkage data depends on distinguishing between thermal expansion and structural softening. Using a 900°C zero-point ensures that displacement readings represent the internal melt formation and shell deformation rather than simple temperature-induced growth.

Eliminating Thermal Noise for Accurate Data

The Problem of Initial Thermal Expansion

Iron ore pellets are not dimensionally stable during the heating process; they expand significantly as they move from room temperature toward higher gradients. If a measurement device captures data from the start of the heating cycle, the initial expansion would offset the subsequent shrinkage, leading to a false calculation of the pellet's behavior.

Establishing the 900°C Benchmark

The device ensures validity by establishing 900°C as the formal starting point for displacement tracking. At this temperature, the primary thermal expansion phase is largely complete, providing a clean "zero" for the measurement of the softening phase.

Isolating Metallurgical Transformations

Monitoring Internal Melt Formation

As the temperature exceeds the 900°C threshold, chemical reactions within the pellet lead to the formation of an internal liquid phase. The displacement device tracks the graphite cover's movement as it sinks, providing a direct measurement of how this melt formation reduces the pellet's structural integrity.

Tracking Metal Shell Deformation

High temperatures cause the metallic shell of the iron ore pellet to weaken and deform under the load of the graphite cover. Valid data in this stage is critical for understanding the high-temperature strength of the pellet, which the displacement device captures by focusing on the physical compression after the expansion phase.

Understanding the Trade-offs

Sensitivity to Reference Accuracy

The validity of the entire test relies on the precision of the 900°C reference point. If the temperature sensors are miscalibrated, the device may start recording too early (capturing expansion) or too late (missing the onset of softening), which compromises the integrity of the shrinkage curve.

Mechanical Friction and Resistance

While the graphite cover provides a stable interface, any mechanical friction within the displacement assembly can resist the movement of the probe. This resistance can lead to an underestimation of the actual shrinkage, making regular maintenance of the device's moving parts essential for data validity.

How to Apply This to Your Project

- If your primary focus is characterizing new ore blends: Ensure the 900°C baseline is strictly adhered to so that results are comparable across different mineral compositions.

- If your primary focus is predicting blast furnace performance: Focus on the rate of displacement after 900°C to determine how quickly the burden will lose permeability as it softens.

Precise displacement measurement transforms raw thermal data into a clear map of the structural transitions that dictate iron ore performance in extreme environments.

Summary Table:

| Feature | Impact on Data Validity | Purpose in Measurement |

|---|---|---|

| 900°C Baseline | Eliminates Thermal Noise | Isolates metallurgical shrinkage from initial expansion. |

| Graphite Cover | Constant Load Application | Simulates realistic pressure for structural collapse tracking. |

| Melt Monitoring | High-Temp Sensitivity | Detects internal liquid phase formation and integrity loss. |

| Shell Deformation | Structural Mapping | Captures the rate of physical compression under heat stress. |

Optimize Your Metallurgical Testing with KINTEK

Precision in iron ore pellet testing requires equipment that can withstand extreme environments without compromising data integrity. Backed by expert R&D and manufacturing, KINTEK offers specialized high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique laboratory needs.

Whether you are characterizing new ore blends or predicting blast furnace performance, our precision-engineered furnaces provide the stability and control required for accurate displacement measurement. Contact us today to discuss how our custom heating solutions can enhance your research and production quality.

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- Why must Ba1-xCaxTiO3 ceramic samples undergo a high-temperature silver-firing process? Ensure Accurate Dielectric Data

- How does a constant temperature and humidity curing chamber contribute to alkali-activated material performance?

- Why is achieving process pressure within defined time important? Boost Efficiency, Quality, and Safety

- What is the purpose of maintaining a 70°C environment in Li-NASICON experiments? Accelerate Your Battery Research

- What is the purpose of a safety warning system in MDR? Ensure Reactor Integrity and Laboratory Safety

- How does the pulling and rotation control system of a Czochralski growth furnace affect crystal quality?

- How can high-temperature furnace systems be used to evaluate and prevent slagging? Optimize Boiler Performance

- What is the primary role of high-temperature thermal simulation systems in steel testing? Optimize Industrial Processes