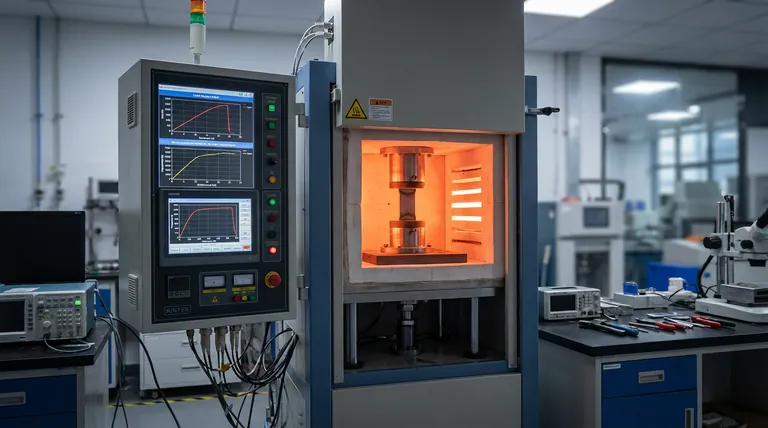

High-temperature thermal simulation systems function as the critical bridge between laboratory testing and industrial application. These systems utilize integrated high-precision heating and hydraulic loading to subject medium-manganese steel specimens to strictly controlled programmed environments. By monitoring load, displacement, and temperature in real-time, they accurately replicate the complex strain rates and thermal conditions encountered during actual manufacturing processes.

The primary value of these systems lies in their ability to generate raw stress-strain data. This data is the foundation for constructing constitutive models and thermal processing maps, which are essential for predicting how steel behaves during industrial thermal processing.

The Mechanics of Accurate Simulation

Integrated Control Systems

To understand medium-manganese steel, one cannot simply heat it or compress it in isolation. The simulation system integrates high-precision heating with hydraulic loading. This combination allows for the execution of complex, pre-programmed testing protocols that mimic real-world scenarios.

Real-Time Monitoring

Data collection is continuous and immediate. The system monitors critical variables—specifically load, displacement, and temperature—as the test progresses. This real-time feedback loop ensures that the conditions applied to the specimen remain within tight tolerances throughout the experiment.

Transforming Raw Data into Engineering Insight

Simulating Industrial Environments

The ultimate goal is to replicate the factory floor within a controlled setting. These systems simulate the specific strain rates and temperature fluctuations that steel undergoes during industrial thermal processing. This capability allows engineers to test processing strategies without the cost or risk of full-scale industrial trials.

Building Constitutive Models

The raw stress-strain data collected is not the end product; it is a raw material. Engineers use this data to construct constitutive models that mathematically describe the material's behavior under stress. These models are vital for predicting the structural integrity and deformability of the steel.

Creating Thermal Processing Maps

Beyond individual models, the data allows for the creation of thermal processing maps. These maps visualize the safe and unsafe processing zones for the material. They guide manufacturers on optimal temperature and strain combinations to avoid defects.

Understanding the Operational Dependencies

The Reliability of Input Parameters

While these systems are powerful, their output is only as reliable as the programmed parameters. If the simulated strain rates or heating curves do not accurately reflect the target industrial process, the resulting data will be misleading. Success requires a deep understanding of the actual manufacturing environment before programming the simulation.

Data Interpretation Challenges

The system provides raw data, but it does not interpret it. Constructing accurate constitutive models requires sophisticated analysis of the stress-strain curves. Misinterpreting the transition points in this data can lead to flawed processing maps.

Maximizing the Value of Thermal Simulation

To effectively utilize high-temperature thermal simulation for medium-manganese steel, align your testing protocols with your specific end goals.

- If your primary focus is material characterization: Prioritize the collection of high-resolution stress-strain data to build robust constitutive models that define the steel's fundamental mechanical behavior.

- If your primary focus is process optimization: Focus on generating comprehensive thermal processing maps to identify the ideal temperature and strain rate windows for industrial manufacturing.

By leveraging these systems to capture precise material responses, you transform theoretical material science into actionable industrial process control.

Summary Table:

| Key Feature | Functional Role | Strategic Benefit |

|---|---|---|

| Integrated Loading | Synchronizes high-precision heating with hydraulic compression | Mimics real-world industrial thermal processing environments |

| Real-time Monitoring | Tracks load, displacement, and temperature continuously | Ensures high-resolution, accurate stress-strain data collection |

| Data Modeling | Foundation for constitutive models and processing maps | Predicts material behavior and identifies optimal processing zones |

| Process Simulation | Replicates complex strain rates and thermal fluctuations | Reduces cost and risk by avoiding full-scale industrial trial failures |

Precision Thermal Simulation for Your Next Innovation

Bridge the gap between laboratory research and industrial success with KINTEK. As a leader in advanced thermal technology, we provide the precision equipment necessary to generate the high-resolution stress-strain data and constitutive models your projects demand.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab equipment including Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temperature furnaces. All our systems are fully customizable to meet the unique testing requirements of medium-manganese steel and other advanced materials.

Ready to transform your material science into actionable industrial control?

Contact KINTEK Today to Discuss Your Custom Solution

References

- Guangshun Guo, Fucheng Zhang. Effects of C and Al Alloying on Constitutive Model Parameters and Hot Deformation Behavior of Medium-Mn Steels. DOI: 10.3390/ma17030732

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the primary technical advantages of using stainless steel for the construction of horizontal pyrolysis furnace bodies? Durability and Thermal Precision

- What are the advantages of using a corundum crucible with a graphite sleeve in AlV55 alloy smelting? Ensure Pure Alloys

- What is the function of magnetron sputtering equipment in Diamond/Cu composites? Enhance Bonding with Precision Coating

- What are the advantages of using an optical floating zone furnace for VNbMoTaW? Achieve Ultra-High Purity Homogenization

- What is the purpose of high-purity argon in heat treating Al-Cu-Mn-Zr-V alloys? Protect Your Material Integrity

- What is the purpose of employing Ozone (O3) treatment following the AS-ALD of Al2O3? Boost Film Purity and Density

- Why is the mechanical mixing of precursor powders necessary for ITO thin films? Guide to Precision Growth

- What role does an industrial oven play in the pretreatment of oil palm shell for biochar? Ensure Peak Biomass Quality