At its core, the equipment used for this process is called a sintering furnace. This is a broad category of high-temperature ovens designed to heat compacted powders to just below their melting point, causing the particles to bond together and densify. Depending on the material and application, this may be a specialized vacuum sintering furnace, a zirconia furnace for dental work, or a continuous conveyor furnace for industrial production.

The specific type of sintering furnace is less important than its function. The critical requirement is a furnace that can provide extremely precise temperature control and a controlled atmosphere (such as a vacuum) to prevent contamination and achieve the desired material density and strength.

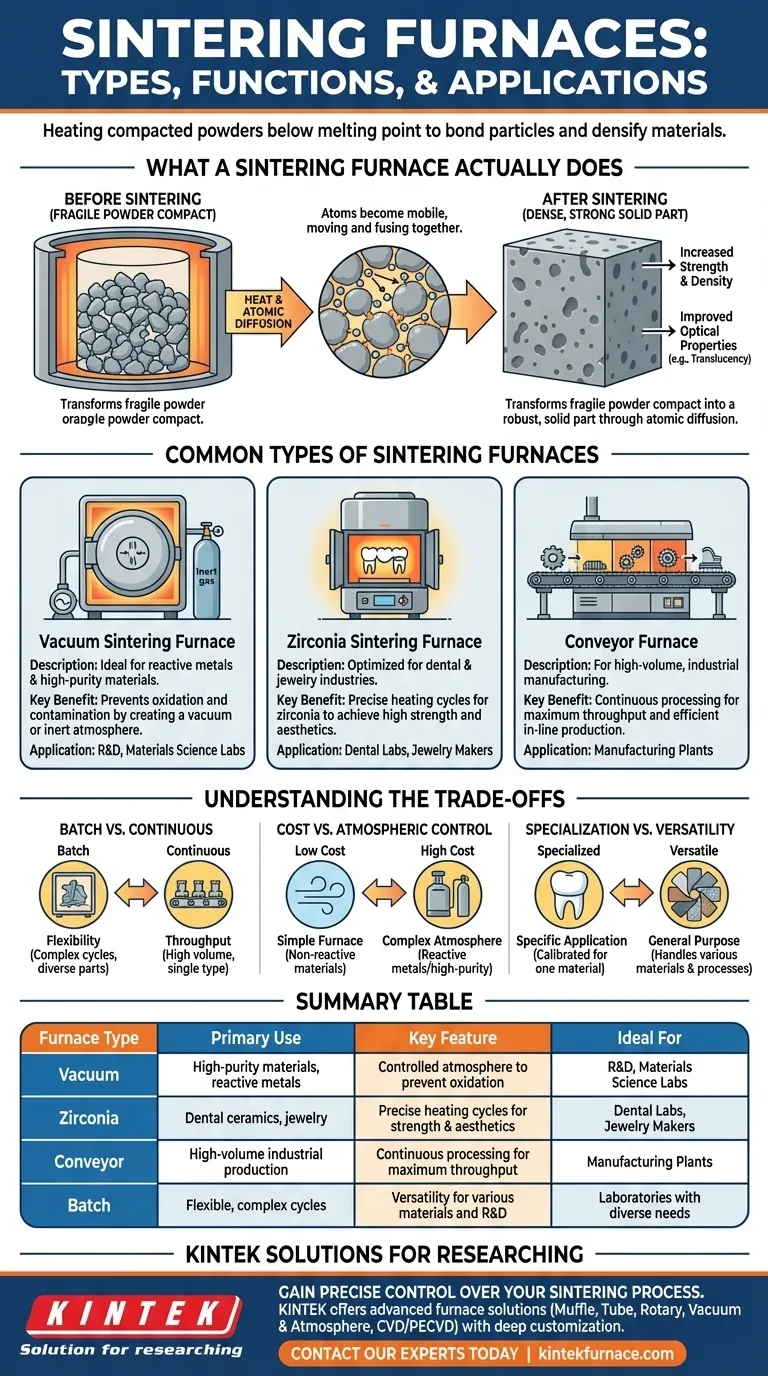

What a Sintering Furnace Actually Does

The purpose of a sintering furnace isn't to melt a material, but to fundamentally change its structure on an atomic level. This process is what transforms a fragile powder compact into a robust, solid part.

The Core Function: Atomic Diffusion

Sintering works by heating a material to a temperature where its atoms become mobile enough to move, or diffuse, across the boundaries of individual particles.

This atomic movement allows the separate powder particles to fuse together, eliminating the empty spaces, or voids, between them. The material never becomes a liquid.

The Key Goals: Increasing Strength and Density

As the voids are eliminated, the part becomes significantly more dense and mechanically strong.

For materials like zirconia, this process also improves optical properties, such as translucency, which is critical for applications in dentistry and jewelry.

Common Types of Sintering Furnaces

While all sintering furnaces share the same basic goal, they are often specialized for different materials, scales of production, and atmospheric requirements.

The Vacuum Sintering Furnace

This is one of the most common and versatile types, designed to heat materials in a vacuum or a controlled inert gas atmosphere.

The primary benefit of the vacuum is to prevent oxidation and contamination. Many metal powders are highly reactive with oxygen at high temperatures, and a vacuum environment protects their purity, preventing defects in the final product.

The Zirconia Sintering Furnace

This is a highly specialized furnace used in the dental and jewelry industries for processing zirconia, a high-performance ceramic.

These furnaces are optimized for the extreme temperatures and precise heating cycles required to properly sinter zirconia, ensuring it achieves its renowned strength, durability, and aesthetic properties.

The Conveyor Furnace

Also known as a continuous furnace, this type is used for high-volume, industrial manufacturing.

Instead of processing parts in individual batches, a conveyor belt continuously moves components through different heating and cooling zones. This allows for an efficient, in-line production process, often paired directly with powder compacting presses.

Understanding the Trade-offs

Choosing a furnace involves balancing throughput, material compatibility, and cost. The right choice for a research lab is often different from the one for a factory floor.

Batch vs. Continuous Processing

A batch furnace (like a vacuum or zirconia furnace) offers high flexibility. It's ideal for complex heating cycles, research and development, or producing a variety of different parts.

A continuous conveyor furnace prioritizes throughput above all else. It is far more efficient for mass-producing a single type of part but lacks the flexibility of a batch furnace.

Cost vs. Atmospheric Control

The ability to create a high vacuum or use a specific protective atmosphere adds significant cost and complexity to a furnace.

For non-reactive materials sintered in air, a simpler and less expensive furnace may suffice. However, for reactive metals or high-purity ceramics where contamination would ruin the part, the investment in a vacuum furnace is non-negotiable.

Specialization vs. Versatility

A specialized zirconia furnace is perfectly calibrated for a dental lab's workflow but is ill-suited for a materials science lab experimenting with various metals. A more general-purpose vacuum furnace offers greater versatility for handling different materials and processes.

Making the Right Choice for Your Goal

Your specific objective dictates which type of sintering furnace is most appropriate.

- If your primary focus is high-purity materials or reactive metals: A vacuum sintering furnace is essential to prevent oxidation and ensure the final part's structural integrity.

- If your primary focus is high-volume, standardized production: A continuous conveyor furnace provides the highest throughput and most efficient workflow.

- If your primary focus is a specific material like dental ceramics: A specialized zirconia sintering furnace is calibrated to deliver consistent, high-quality results for that application.

Ultimately, selecting the right furnace is about gaining precise control over the material's final properties.

Summary Table:

| Furnace Type | Primary Use | Key Feature | Ideal For |

|---|---|---|---|

| Vacuum Sintering Furnace | High-purity materials, reactive metals | Controlled atmosphere to prevent oxidation | R&D, Materials Science Labs |

| Zirconia Sintering Furnace | Dental ceramics, jewelry | Precise heating cycles for strength & aesthetics | Dental Labs, Jewelry Makers |

| Conveyor Furnace | High-volume industrial production | Continuous processing for maximum throughput | Manufacturing Plants |

| Batch Furnace | Flexible, complex cycles | Versatility for various materials and R&D | Laboratories with diverse needs |

Gain Precise Control Over Your Sintering Process

Choosing the right sintering furnace is critical to achieving the desired density, strength, and properties in your final product. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique requirements.

Our diverse product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, complemented by strong deep customization capabilities. Whether you need a high-purity vacuum furnace for reactive metals, a specialized zirconia furnace for dental applications, or a high-throughput conveyor system for industrial production, we can deliver a precise solution.

Ready to enhance your lab's capabilities? Contact our experts today to discuss your specific sintering challenges and let us help you build the perfect furnace for your goals.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations