At its core, a dental sintering furnace is a specialized high-temperature oven essential for the final production stage of many dental restorations. It executes a controlled heating process, known as sintering, that transforms milled materials like zirconia from a soft, chalk-like state into a hard, dense, and biocompatible final product ready for clinical use.

A sintering furnace is not merely a heating device; it is the critical final step in the digital dentistry workflow that determines the ultimate strength, fit, and profitability of advanced ceramic restorations like crowns and bridges.

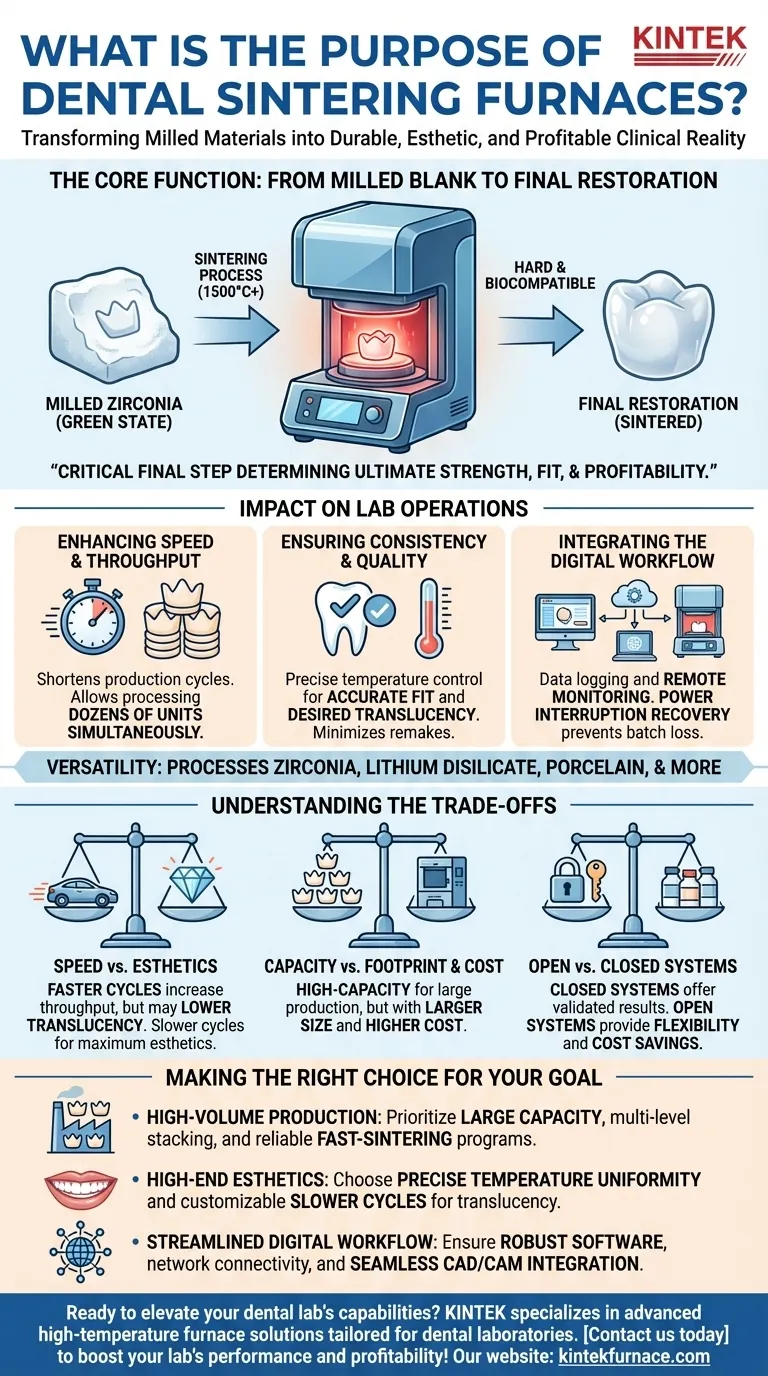

The Core Function: From Milled Blank to Final Restoration

The primary role of the furnace is to fuse material particles together under precise heat, fundamentally changing their physical properties. This process is what gives modern dental ceramics their exceptional durability and esthetics.

What is Sintering?

Sintering is the process of compacting and forming a solid mass of material by heat without melting it to the point of liquefaction. In dentistry, this means taking a pre-shaped, porous restoration and heating it until the particles bond, causing it to shrink and densify.

The Transformation of Zirconia

Zirconia is the most common material requiring sintering. Dental labs first use a CAD/CAM system to mill a restoration from a block of pre-sintered zirconia. This "green state" material is soft and easy to mill but lacks the required strength. The sintering furnace then executes a precise heating and cooling cycle, often exceeding 1,500°C (2,732°F), to achieve its final, high-strength form.

Versatility with Other Materials

Modern furnaces are not limited to zirconia. Many are designed to process a range of materials, including lithium disilicate and other pressable or sinterable ceramics. They are also used for firing porcelain, applying stains and glazes, and oxidizing metal substructures for traditional porcelain-fused-to-metal (PFM) restorations.

How Sintering Furnaces Impact Lab Operations

A sintering furnace is a significant investment that directly influences a dental lab's efficiency, output quality, and financial performance. Its impact extends far beyond the heating chamber.

Enhancing Speed and Throughput

Compared to older methods, modern sintering furnaces dramatically shorten the production cycle. Features like fast sintering programs and the ability to stack multiple trays allow a lab to process dozens or even hundreds of units (crowns, bridges) simultaneously.

Ensuring Consistency and Quality

The furnace is a gatekeeper for quality. Precise temperature control and evenly distributed heat are critical for achieving consistent shrinkage, accurate fit, and desired translucency. A high-quality furnace produces predictable results, which minimizes the need for costly remakes.

Integrating the Digital Workflow

Many advanced furnaces integrate with the lab's CAD/CAM ecosystem. Features like power interruption recovery prevent the loss of a full batch during a power flicker, while data logging and remote monitoring help labs track performance and maintain quality control standards.

Understanding the Trade-offs

While essential, choosing and operating a furnace involves balancing competing priorities. Understanding these trade-offs is key to making an informed decision and optimizing its use.

Speed vs. Esthetics

The most common trade-off is between speed and esthetics, particularly with zirconia. Faster sintering cycles can increase throughput but may result in lower translucency, which is critical for anterior restorations. Slower, longer cycles are often used to achieve the highest level of esthetic appeal.

Capacity vs. Footprint and Cost

High-capacity furnaces that can sinter over 100 units at once are ideal for large production labs, but they come with a larger physical footprint and a higher initial cost. Smaller labs must balance their current and future production needs against budget and space constraints.

Open vs. Closed Systems

Some furnaces are optimized or "closed" for use with a specific manufacturer's brand of materials. While this can ensure validated results, an open-system furnace offers greater flexibility to use materials from any supplier, which can lead to cost savings and more options.

Making the Right Choice for Your Goal

Selecting the correct furnace depends entirely on your laboratory's specific priorities and business model.

- If your primary focus is high-volume production: Prioritize furnaces with a large chamber capacity, multi-level stacking, and proven, reliable fast-sintering programs.

- If your primary focus is high-end esthetics: Choose a furnace renowned for its precise temperature uniformity and customizable programs that allow for slower cycles to maximize material translucency.

- If your primary focus is a streamlined digital workflow: Ensure the furnace offers robust software, network connectivity, and seamless integration with your existing CAD/CAM system.

Ultimately, the right sintering furnace is the one that reliably transforms your digital designs into durable, esthetic, and profitable clinical reality.

Summary Table:

| Aspect | Key Details |

|---|---|

| Primary Function | Sintering milled materials (e.g., zirconia) to achieve hardness and density |

| Common Materials | Zirconia, lithium disilicate, porcelain, metal substructures |

| Temperature Range | Often exceeds 1,500°C (2,732°F) |

| Key Benefits | Enhanced strength, consistent fit, improved esthetics, faster production cycles |

| Trade-offs | Speed vs. esthetics, capacity vs. cost, open vs. closed systems |

| Ideal For | Dental labs focusing on high-volume production, high-end esthetics, or streamlined digital workflows |

Ready to elevate your dental lab's capabilities? KINTEK specializes in advanced high-temperature furnace solutions tailored for dental laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental and production needs—ensuring reliable, efficient sintering for durable and esthetic restorations. Contact us today to discuss how our furnaces can boost your lab's performance and profitability!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab