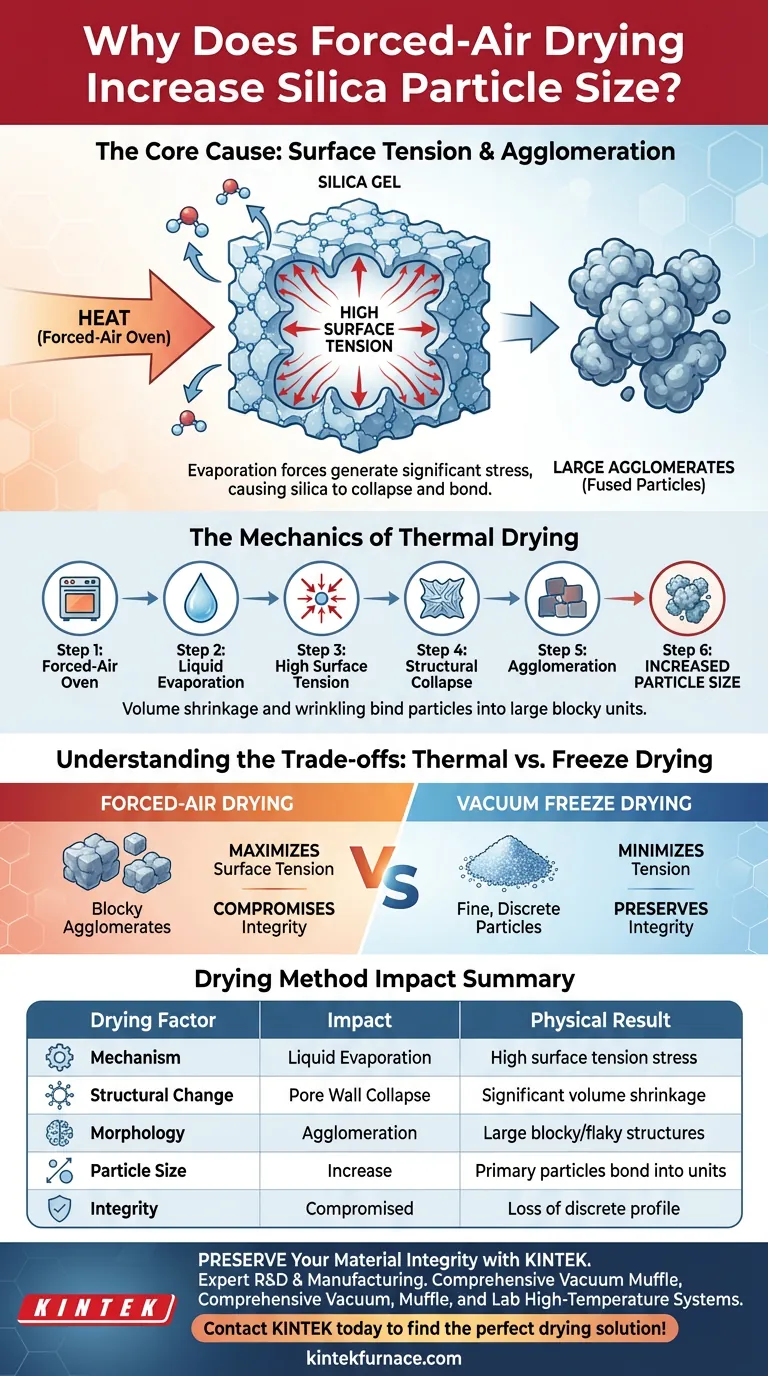

Forced-air drying increases particle size primarily through the formation of agglomerates caused by surface tension. When a silica sample is dried in a conventional thermal oven, the evaporation of liquid water generates significant physical stress on the material. This stress forces the silica structure to collapse and bond together, creating large, irregular clumps rather than preserving fine, discrete particles.

The removal of liquid water via heat creates high surface tension that shrinks and wrinkles the silica gel. This structural collapse results in strong interactions between particles, forming large "blocky" agglomerates that significantly inflate the measured average particle size.

The Mechanics of Thermal Drying

The Role of Surface Tension

In a forced-air oven, the drying process relies on the evaporation of liquid water. As water leaves the pores of the silica gel, it exerts significant surface tension on the pore walls.

Structural Collapse

This tension creates a powerful inward pulling force. Consequently, the silica gel undergoes severe volume shrinkage and wrinkling as the internal structure is pulled together.

The Formation of Agglomerates

Creating "Blocky" Structures

The strong interactions caused by shrinkage do not just reduce the volume of individual particles; they bind them together. The material consolidates into large blocky or flaky agglomerates.

Impact on Measurement

Because these particles are fused together, they act as single, much larger units during analysis. This results in an average particle size that is substantially larger than the inherent size of the primary silica particles.

Understanding the Trade-offs

Thermal vs. Freeze Drying

It is critical to recognize that this particle growth is specific to the method of water removal. Forced-air ovens rely on liquid evaporation, which maximizes surface tension.

The Cost of Convenience

While thermal drying is often faster or more accessible, it compromises the morphological integrity of the sample. In contrast, methods like vacuum freeze drying bypass the liquid phase, minimizing tension and preserving smaller particle sizes.

Making the Right Choice for Your Goal

To determine the best drying method for your silica application, consider the following:

- If your primary focus is minimizing particle size: Avoid forced-air drying, as the surface tension will inevitably cause agglomeration and shrinkage.

- If your primary focus is structural preservation: Utilize vacuum freeze drying to prevent the formation of large blocky agglomerates.

The method of drying is not just a finishing step; it is a determinant of the final material's physical dimensions.

Summary Table:

| Drying Factor | Impact on Silica Samples | Physical Result |

|---|---|---|

| Mechanism | Liquid Evaporation | High surface tension stress |

| Structural Change | Pore Wall Collapse | Significant volume shrinkage |

| Morphology | Agglomeration | Large blocky/flaky structures |

| Particle Size | Increase | Primary particles bond into units |

| Integrity | Compromised | Loss of discrete particle profile |

Preserve Your Material Integrity with KINTEK

Don't let surface tension compromise your research results. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Vacuum, Muffle, and customizable lab high-temperature systems designed to give you precise control over your material morphology. Whether you need to prevent silica agglomeration or require specialized thermal processing, our team can tailor a solution for your unique laboratory needs.

Contact KINTEK today to find the perfect drying solution for your application!

Visual Guide

References

- Shengwang Yuan, Yunhai Ma. A Comparative Study on Rice Husk, as Agricultural Waste, in the Production of Silica Nanoparticles via Different Methods. DOI: 10.3390/ma17061271

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the function of a high-pressure reactor in hydrothermal carbonization? Master Biomass Conversion Efficiency

- How does a plasma surface metallurgy furnace achieve infiltration? Engineer High-Performance Diffusion Bonds

- How does a high-precision temperature control system influence the nanoparticle size? Master Catalyst Activation

- Why is it necessary to preheat casting molds to 300°C? Expert Thermal Control for Recycled Aluminum Alloy Production

- How does the secondary calcination process improve Na2WO4-loaded catalysts? Optimize Surface Performance Today

- How does substrate preheating equipment affect the formation and distribution of the Laves phase in Inconel 718?

- Why is a forced air drying oven essential after molding biomass briquettes? Enhance Fuel Quality & Strength

- Why is thermal decomposition in a high-temperature furnace necessary for PVDF removal? Unlocking Battery Recycling Efficiency