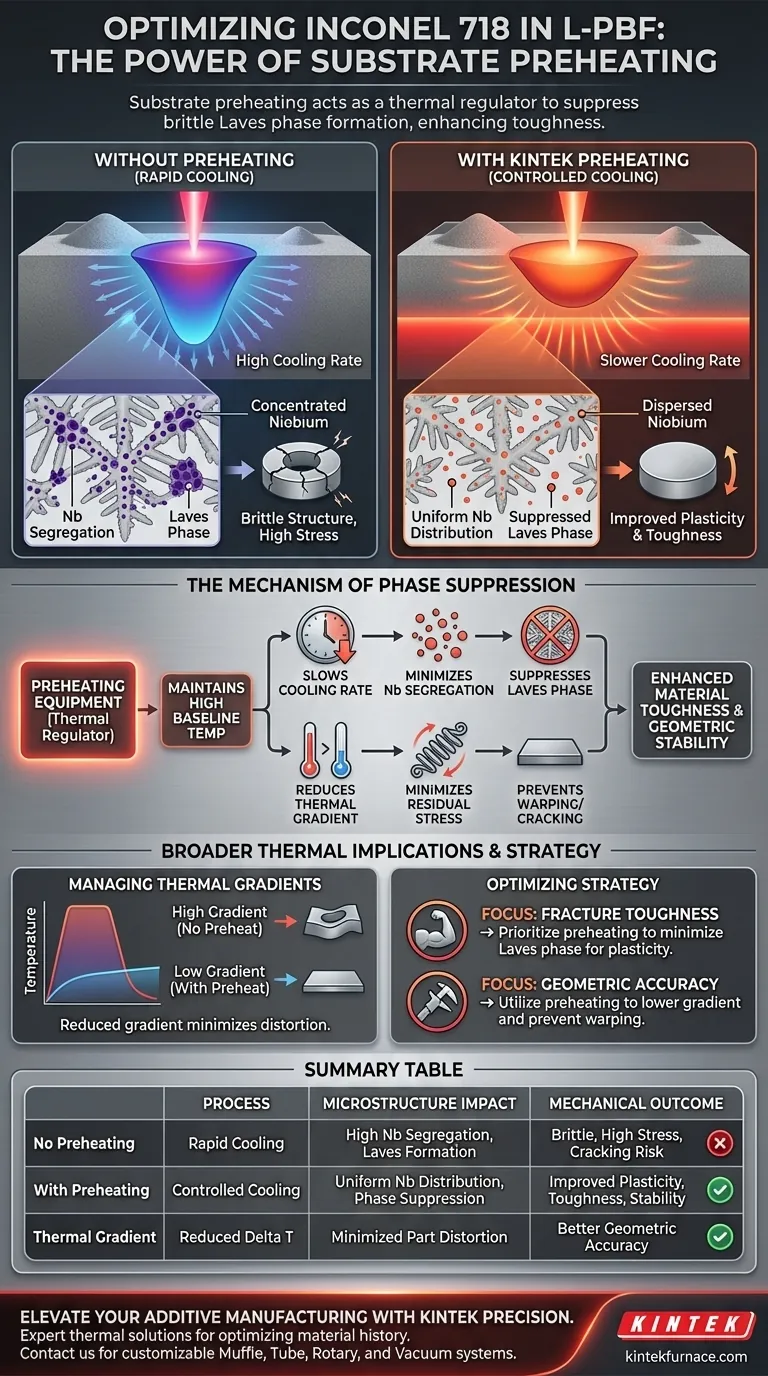

Substrate preheating equipment acts as a critical thermal regulator to suppress the formation of the brittle Laves phase in Inconel 718. By maintaining a high-temperature environment within the formation zone, the equipment significantly reduces the cooling rate of the molten pool. This controlled cooling minimizes the segregation of Niobium (Nb), preventing it from concentrating in the spaces between dendrites where the Laves phase typically creates structural weaknesses.

Inconel 718 is prone to forming the brittle Laves phase due to the rapid cooling inherent in Laser Powder Bed Fusion (L-PBF). Substrate preheating optimizes the material's thermal history to disperse Niobium, reducing Laves content and directly improving the alloy's plasticity and toughness.

The Mechanism of Phase Suppression

Controlling the Cooling Rate

The primary function of preheating equipment is to alter the thermal history of the build.

In standard L-PBF processes, the molten pool cools extremely fast. Preheating the substrate maintains a higher baseline temperature in the formation zone, which effectively slows down this cooling rate.

Minimizing Niobium Segregation

The formation of the Laves phase is directly linked to the behavior of Niobium (Nb).

Under rapid cooling conditions, Nb tends to segregate, or cluster, within the interdendritic spaces (the gaps between crystal structures). Preheating prevents this aggregation by allowing more time for diffusion, keeping the Nb more evenly distributed throughout the matrix.

Enhancing Material Toughness

The presence of the Laves phase is detrimental because it creates brittleness in the final part.

By preventing Nb aggregation, preheating reduces the overall content of the Laves phase in both the as-built and post-heat-treated material. This microstructural improvement leads to a direct increase in the plasticity and toughness of the Inconel 718 alloy.

Broader Thermal Implications and Risks

Managing Thermal Gradients

While the primary goal regarding the Laves phase is chemical distribution, preheating also addresses physical stress.

Without preheating, the sharp temperature difference between the molten pool and the cooler substrate creates a steep temperature gradient. This gradient drives the accumulation of residual stress, which can lead to part distortion or cracking.

The Risk of Insufficient Heating

Setting the preheat temperature too low (or forgoing it entirely) leaves the alloy vulnerable to thermal shock.

As noted in supplementary data regarding similar processes, maintaining a temperature around 200°C helps mitigate the tendency for cracking caused by thermal expansion and contraction. For specific materials, this also ensures the stability of the molding process and improves the wettability of the melt pool.

Optimizing Your L-PBF Process Strategy

To achieve the best mechanical properties in Inconel 718, you must view preheating as a metallurgical tool, not just a process aid.

- If your primary focus is Fracture Toughness: Prioritize preheating to minimize the Laves phase, as this directly reduces brittleness and enhances the material's plasticity.

- If your primary focus is Geometric Accuracy: Utilize preheating to lower the thermal gradient, which reduces residual stress and prevents warping or cracking during the build.

Effective preheating transforms the microstructure of Inconel 718 from a brittle, segregated state into a tough, uniform alloy.

Summary Table:

| Process Parameter | Impact on Microstructure | Mechanical Outcome |

|---|---|---|

| No Preheating | Rapid cooling, high Nb segregation, Laves phase formation | Brittle parts, high residual stress, cracking risk |

| With Preheating | Controlled cooling, uniform Nb distribution, phase suppression | Improved plasticity, toughness, and geometric stability |

| Thermal Gradient | Reduced temperature delta between pool and substrate | Minimized part distortion and warping |

Elevate Your Additive Manufacturing with KINTEK Precision

Don't let brittle Laves phases compromise the integrity of your Inconel 718 components. Backed by expert R&D and manufacturing, KINTEK offers high-performance thermal solutions, including customizable Muffle, Tube, Rotary, and Vacuum systems designed to optimize your material's thermal history. Whether you are performing critical research or industrial production, our equipment ensures the precise temperature control needed to enhance material toughness and eliminate residual stress.

Ready to optimize your high-temperature processes? Contact our technical experts today to find the perfect furnace solution for your unique laboratory or production needs.

Visual Guide

References

- Koji Kakehi, Shohei Ishisako. Effects of base plate temperature on microstructure evolution and high-temperature mechanical properties of IN718 processed by laser powder bed fusion using simulation and experiment. DOI: 10.1007/s00170-024-13028-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a fusion process using lithium metaborate necessary for the elemental analysis of S53P4 bioactive glass?

- How does the structure of a shaft furnace facilitate the reduction of iron ore? Mastering High-Temp Heat Exchange

- Why use a precision oven for moxa floss samples? Ensure Accurate Air-Drying Basis for Combustion Research

- What is the technical necessity of heating and stirring for K-Na alloy anodes? Ensure Peak Battery Performance

- How does a cooling circulation unit assist in plastic pyrolysis? Optimize Bio-Oil & Gas Separation

- Why do VTD sublimation capsules need specialized designs for perovskite? Achieve Precise Film Uniformity and Stability

- What is the primary role of the Thermal Oxidation (TO) process in Ti-6Al-4V ELI alloy? Enhancing Hardness and Wear

- What is the purpose of coating aluminum electrodes with Au80Pd20? Enhancing Precision in Nanoparticle Characterization