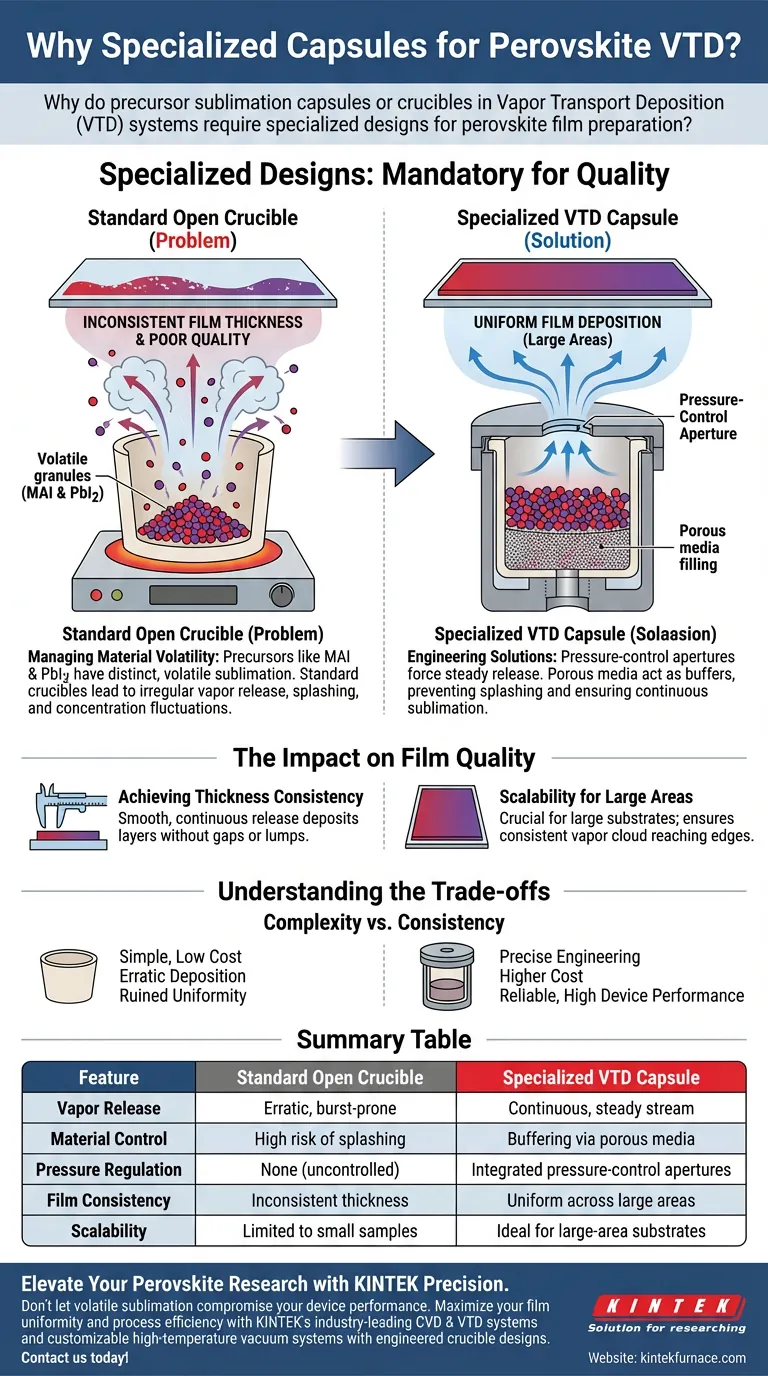

Specialized designs for sublimation capsules are mandatory because perovskite precursors like methylammonium iodide (MAI) and lead iodide (PbI2) possess distinct and often volatile sublimation characteristics. Without these engineered physical constraints, the heating process causes erratic vapor release, leading to inconsistent film thickness and poor quality across the substrate.

Core Takeaway Standard open crucibles cannot maintain the steady vapor flow required for high-quality Vapor Transport Deposition (VTD). Specialized designs utilize mechanisms like pressure-control apertures and porous media to transform volatile precursor sublimation into a continuous, stable stream, ensuring uniform film deposition over large areas.

Managing Material Volatility

The Instability of Perovskite Precursors

In VTD systems, the materials used to create perovskite films—specifically MAI and PbI2—do not sublime at perfectly even rates on their own.

When heated, these precursors are prone to sudden physical changes. This can manifest as splashing or unpredictable spikes in vapor concentration.

The Risk of Uncontrolled Release

If the vapor is released directly from a standard container, the flow into the carrier gas becomes erratic.

This turbulence creates concentration fluctuations, meaning the amount of material landing on the substrate varies from moment to moment.

The Engineering Solutions

Pressure-Control Apertures

To counteract volatility, specialized capsules often feature pressure-control apertures.

These are restricted openings that physically limit how fast vapor can escape. This builds a small amount of back-pressure, forcing the vapor to exit at a steady, controlled rate rather than in varied bursts.

Porous Media Fillings

Another critical design element is the inclusion of porous media inside the crucible.

These materials act as a buffer or physical sponge. They prevent the precursors from splashing during heating and help regularize the sublimation surface area, contributing to a continuous release profile.

The Impact on Film Quality

Achieving Thickness Consistency

The ultimate goal of stabilizing vapor flow is to ensure the film thickness is identical across the entire substrate.

By smoothing out the release of precursors, the VTD system deposits layers without gaps or lumps.

Scalability for Large Areas

This control becomes critical when working with large-area substrates.

On a large surface, even minor fluctuations in vapor concentration result in visible defects. Specialized capsules ensure that the "cloud" of vapor reaching the far edges of the substrate is just as consistent as the vapor at the center.

Understanding the Trade-offs

Complexity vs. Consistency

The primary trade-off in VTD design is the added complexity of the hardware versus the quality of the output.

Using simple, open crucibles allows for easier loading and lower equipment costs, but it inevitably leads to erratic deposition rates.

The Cost of Simplicity

Foregoing specialized designs invites sudden splashing, which ruins the uniformity of the film.

While specialized capsules require more precise engineering, they are the only reliable method to prevent the concentration fluctuations that compromise device performance.

Making the Right Choice for Your Goal

To determine the necessity of these designs for your specific application, consider the following:

- If your primary focus is large-scale manufacturing: You must use capsules with pressure-control apertures to ensure uniformity across the entire width of the substrate.

- If your primary focus is preventing material waste: You should prioritize designs with porous media fillings to prevent splashing and ensure every gram of precursor is sublimed efficiently.

In VTD systems, the stability of your hardware directly dictates the uniformity of your film.

Summary Table:

| Feature | Standard Open Crucible | Specialized VTD Capsule |

|---|---|---|

| Vapor Release | Erratic, burst-prone | Continuous, steady stream |

| Material Control | High risk of splashing | Buffering via porous media |

| Pressure Regulation | None (uncontrolled) | Integrated pressure-control apertures |

| Film Consistency | Inconsistent thickness | Uniform across large areas |

| Scalability | Limited to small samples | Ideal for large-area substrates |

Elevate Your Perovskite Research with KINTEK Precision

Don't let volatile sublimation compromise your device performance. KINTEK provides industry-leading CVD and VTD systems, backed by expert R&D and specialized manufacturing. Whether you need standard muffle furnaces or customizable high-temperature vacuum systems with engineered crucible designs, our team is ready to support your unique material requirements.

Maximize your film uniformity and process efficiency—contact KINTEK today to discuss your specialized lab equipment needs!

Visual Guide

References

- Dachang Liu. Vapor Transport Deposition Technology for Perovskite Films. DOI: 10.1002/admi.202500064

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a high-temperature sintering furnace ensure structural integrity? Expert Thermal Management Guide

- How does a gas mass flow control system (MFC) prevent copper foil adhesion? Mastering Atmospheric Purity

- How does the secondary calcination process improve Na2WO4-loaded catalysts? Optimize Surface Performance Today

- Why is a blast drying oven required for the pretreatment of chromite pellets? Prevent Structural Failure & Steam Cracks

- What is Joule Heating and how does it relate to induction heating? Master the Physics of Contactless Heating

- How do water quenching and furnace cooling methods differ in their application to high-entropy alloys? Expert Insights

- What are the advantages of a high-pressure nitrogen environment? Speed and Efficiency in Wood Thermal Modification

- What is the primary purpose of using a vacuum drying oven at 100°C? Optimize Aluminum Foil Coating Performance