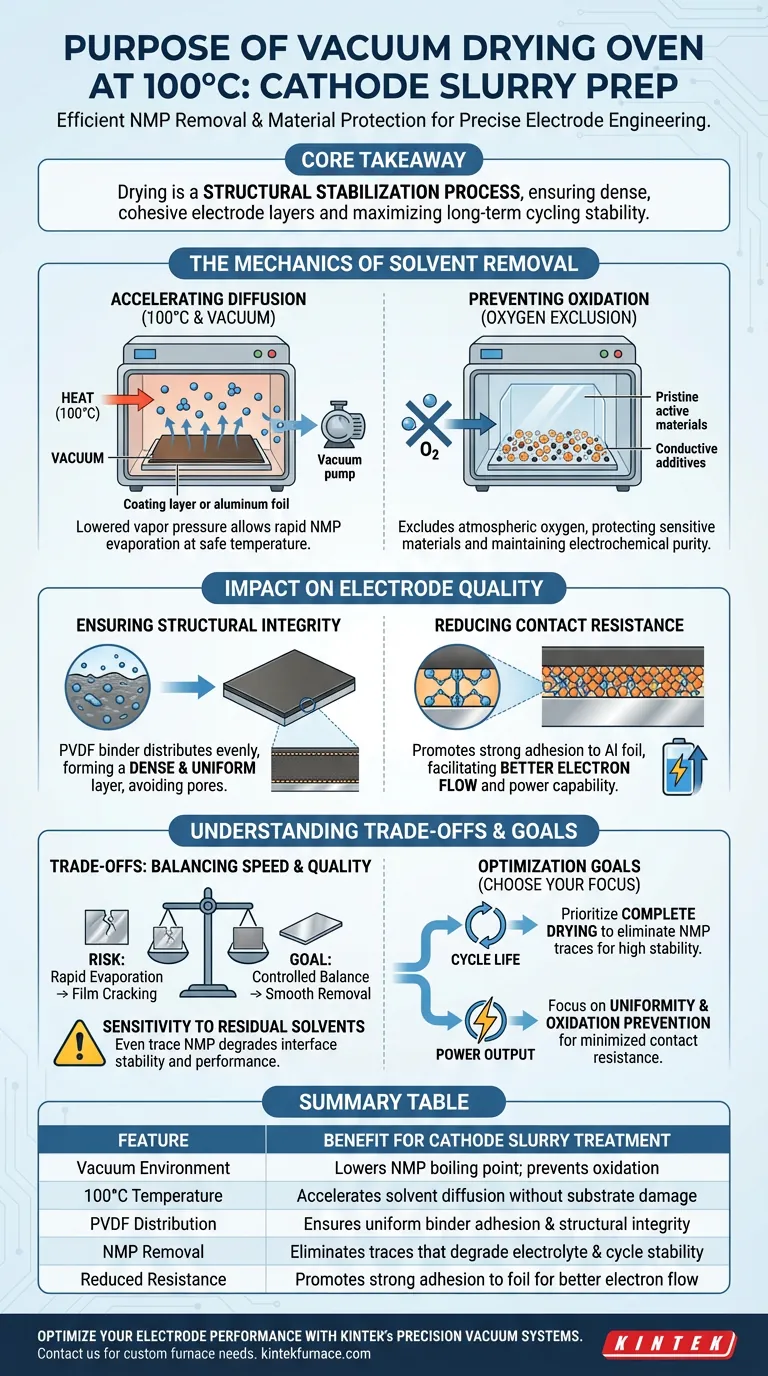

The specific application of a vacuum drying oven at 100°C plays a critical role in the precise engineering of cathode electrodes. Its primary function is to effectively remove N-Methyl-2-pyrrolidone (NMP) solvents from the slurry mixture coated on the aluminum foil. By combining heat with a vacuum environment, this process accelerates solvent diffusion while strictly preventing the oxidation of sensitive active materials.

Core Takeaway Drying at this specific temperature and pressure is not merely about evaporation; it is a structural stabilization process. It ensures the formation of a dense, cohesive electrode layer that minimizes contact resistance and maximizes the long-term cycling stability of the battery.

The Mechanics of Solvent Removal

Accelerating Diffusion at Controlled Temperatures

The NMP solvent used in cathode slurries has a relatively high boiling point. Attempting to remove it at atmospheric pressure often requires excessive heat, which can damage battery components.

By utilizing a vacuum environment, the vapor pressure is lowered. This allows the NMP solvent molecules to diffuse and evaporate rapidly at 100°C, a temperature that is effective for drying but safe for the aluminum substrate and active materials.

Preventing Oxidation

Standard drying methods expose materials to atmospheric oxygen, which acts as a contaminant in battery chemistry.

The vacuum oven excludes oxygen during the heating process. This is vital for protecting the active materials and conductive additives (such as acetylene black) from oxidation, preserving their electrochemical purity before the battery is even assembled.

Impact on Electrode Quality

Ensuring Structural Integrity

The drying phase is where the slurry transforms into a solid electrode. The vacuum process ensures that the PVDF binder distributes evenly as the solvent leaves.

This results in a dense and uniform electrode layer. Without this controlled removal, the coating could suffer from uneven density or microscopic pores that hinder performance.

Reducing Contact Resistance

A battery's efficiency depends heavily on how well the coating sticks to the current collector (the aluminum foil).

The 100°C vacuum treatment promotes strong adhesion between the active material, the binder, and the foil. This strong bond directly reduces contact resistance, facilitating better electron flow and enhancing the overall power capability of the cell.

Understanding the Trade-offs

The Risk of Rapid Evaporation

While the vacuum accelerates drying, aggressive pressure changes can be a double-edged sword.

If the solvent evaporates too violently, it can cause film cracking or structural defects in the coating. The process relies on a balance between the 100°C heat and the vacuum level to ensure smooth, rather than disruptive, solvent removal.

Sensitivity to Residual Solvents

This process leaves no margin for error regarding moisture or solvent retention.

Even trace amounts of NMP left behind due to insufficient time or vacuum depth can react with the electrolyte later. This reaction degrades the interface stability, neutralizing the benefits of the vacuum drying step.

Making the Right Choice for Your Goal

To maximize the performance of your cathode preparation, consider your specific optimization targets:

- If your primary focus is Cycle Life: Prioritize the completeness of the drying phase to eliminate all NMP traces, ensuring high cycling stability and preventing electrolyte degradation.

- If your primary focus is Power Output: Focus on the prevention of oxidation and the uniformity of the binder distribution to minimize contact resistance for efficient energy transfer.

The vacuum drying oven is not just a dehydrator; it is the tool that locks in the chemical potential of your electrode materials.

Summary Table:

| Feature | Benefit for Cathode Slurry Treatment |

|---|---|

| Vacuum Environment | Lowers NMP boiling point; prevents oxidation of active materials |

| 100°C Temperature | Accelerates solvent diffusion without damaging the aluminum substrate |

| PVDF Distribution | Ensures uniform binder adhesion and structural integrity |

| NMP Removal | Eliminates traces that degrade electrolyte and cycle stability |

| Reduced Resistance | Promotes strong adhesion to foil for better electron flow |

Optimize Your Electrode Performance with KINTEK

Precision in solvent removal is the difference between a high-performance cell and a failing one. Backed by expert R&D and manufacturing, KINTEK offers specialized Vacuum, Muffle, and CVD systems, along with other lab high-temp furnaces, all customizable for your unique battery research needs. Whether you are scaling up cathode production or refining lab-scale coatings, our technology ensures the thermal and atmospheric control required for superior electrode quality.

Ready to enhance your lab's efficiency and battery cycling stability? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Kexin Zheng, Lu Ju. Effects of Ti4+ Doping on the Structural Stability and Electrochemical Performance of Layered P2-Na0.7MnO2.05 Cathodes for Sodium-Ion Batteries. DOI: 10.3390/nano14241989

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the energy consumption considerations when choosing between separate or combined debinding and sintering furnaces? Optimize Your Process Efficiency

- What role does an industrial fast firing furnace play in the metallization of PERT solar cells? Boost Cell Efficiency

- Why is a vibratory mill used for ultra-fine grinding when preparing magnesite samples for zeta potential tests?

- What is the impact of using a vacuum drying oven on CDI electrodes? Optimize Stability and Conductivity

- What are the advantages of using a vacuum oven for drying porous carbon? Protect Microstructures & Prevent Oxidation

- What are the advantages of supersonic inert gas cooling in DGCC? Transform Heat Treatment and Microstructure Control

- What are the primary applications of a high-precision electric furnace in biomass characterization? Unlock Key Insights

- How does the temperature field provided by a High-Temperature Reaction Furnace promote pore development? 700-800°C Mastery