The industrial fast firing furnace serves as the critical final step in the metallization of PERT solar cells, transforming screen-printed pastes into functional electrical contacts. By subjecting the wafers to a precisely controlled, high-speed thermal cycle, this equipment enables the metal to breach insulating layers and bond directly with the silicon substrate.

The fast firing furnace bridges the gap between physical printing and electrical functionality. Its primary function is to drive metal paste through the passivation layer to form low-resistance ohmic contacts without damaging the cell's delicate semiconductor junction.

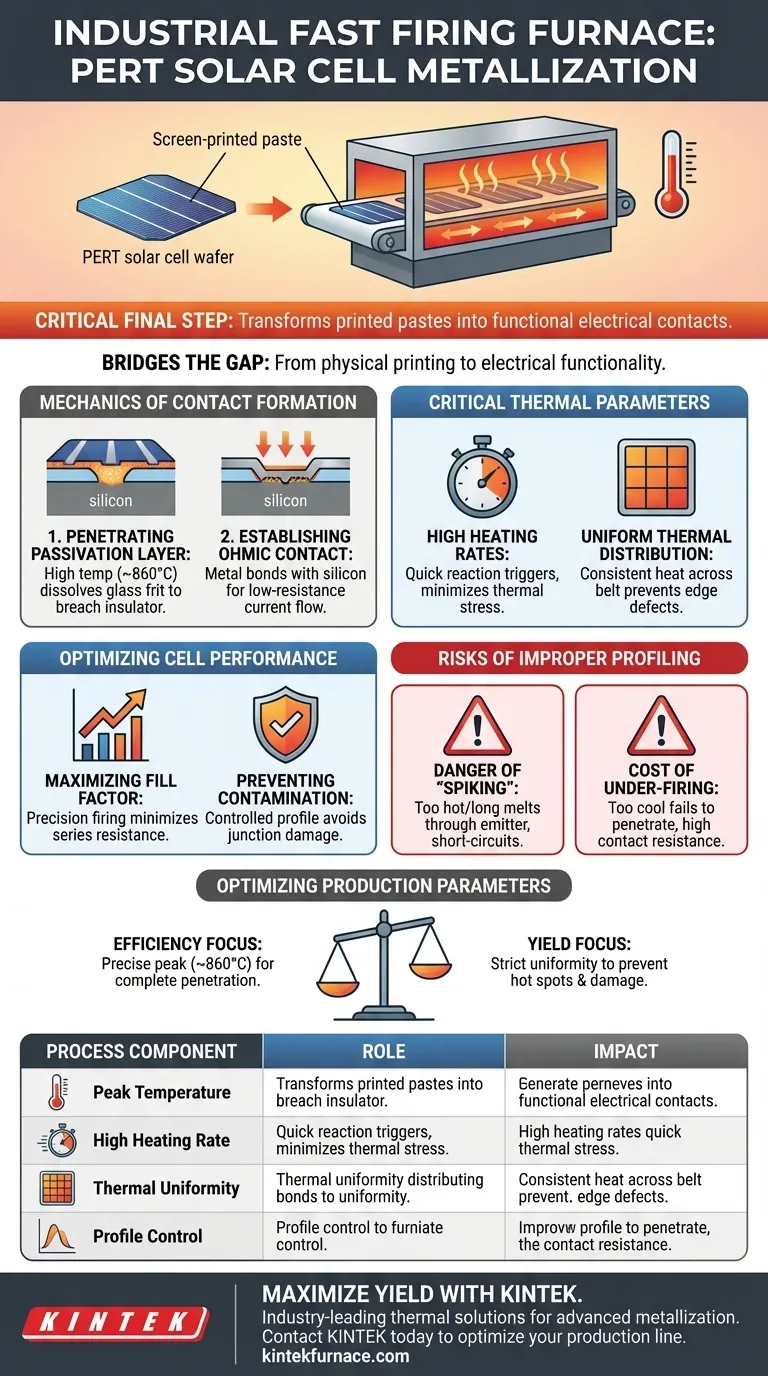

The Mechanics of Contact Formation

Penetrating the Passivation Layer

PERT solar cells are coated with a dielectric passivation layer that insulates the surface. To collect current, the metal contacts must break through this barrier.

The fast firing furnace achieves this by ramping the cell to a specific peak temperature, typically around 860 °C. At this intensity, the glass frit in the metal paste dissolves the passivation layer, allowing the metal to reach the silicon beneath.

Establishing Ohmic Contact

Once the barrier is breached, the metal interacts with the silicon substrate. This interaction creates a reliable ohmic contact.

A high-quality ohmic contact is essential for allowing charge carriers to flow freely out of the cell. Without this connection, the energy generated by the solar cell remains trapped, rendering the device useless.

Critical Thermal Parameters

High Heating Rates

The "fast" in fast firing is not just for throughput; it is a chemical necessity. A rapid increase in temperature is required to trigger the necessary reactions quickly.

This speed ensures that the contact forms immediately, limiting the time the wafer spends under high thermal stress.

Uniform Thermal Distribution

The furnace must maintain a strictly uniform thermal field across the entire width of the transport belt.

If the heat distribution is uneven, the center of the wafer might fire perfectly while the edges remain under-processed. Uniformity ensures consistent electrical performance across the entire surface area of every cell.

Optimizing Cell Performance

Maximizing Fill Factor

The precision of the firing process is directly linked to the solar cell's fill factor.

The fill factor is a measure of the "squareness" of the IV curve and represents the efficiency of current collection. By optimizing the firing profile, manufacturers minimize series resistance and maximize this critical performance metric.

Preventing Deep-Level Contamination

While heat is necessary to form contacts, it is also a liability. Excessive thermal exposure can cause metal atoms to diffuse too deeply into the silicon.

The fast firing furnace is designed to prevent this deep-level contamination. By controlling the profile, it ensures metal touches the emitter but does not penetrate the junction area, which would cause electrical shunts.

Risks of Improper Thermal Profiling

The Danger of "Spiking"

If the peak temperature is too high or held for too long, the metal paste can melt through the emitter region.

This phenomenon, known as spiking, effectively short-circuits the local area of the cell. This damage is irreversible and significantly degrades the cell's open-circuit voltage.

The Cost of Under-firing

Conversely, if the furnace fails to reach the required peak temperature, the paste will not fully etch through the passivation layer.

This results in "under-firing," where the metal sits on top of the insulator rather than contacting the silicon. The result is extremely high contact resistance and a non-functional solar cell.

Optimizing Your Production Parameters

Achieving high-efficiency PERT cells requires a delicate balance between aggressive heating for contact formation and restraint for junction protection.

- If your primary focus is maximizing electrical efficiency: Prioritize a precise peak temperature near 860 °C to ensure complete passivation penetration and minimal contact resistance.

- If your primary focus is minimizing yield loss: Strictly maintain thermal field uniformity to prevent hot spots that lead to deep-level metal contamination and junction damage.

Precision in the firing furnace is the final gatekeeper that determines whether a processed wafer becomes a high-performance energy generator or scrap.

Summary Table:

| Process Component | Role in PERT Metallization | Impact on Performance |

|---|---|---|

| Peak Temperature (~860°C) | Dissolves glass frit to penetrate passivation layers | Ensures metal-to-silicon contact |

| High Heating Rate | Rapidly triggers chemical reactions in metal paste | Minimizes thermal stress on wafers |

| Thermal Uniformity | Ensures consistent processing across the entire belt | Prevents edge defects and yield loss |

| Profile Control | Limits metal diffusion depth | Prevents electrical shunts and spiking |

Maximize Your PERT Solar Cell Yield with KINTEK

Precision is the difference between a high-performance energy generator and scrap. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Our customizable Muffle, Tube, and Vacuum systems are engineered to deliver the strict thermal field uniformity and rapid ramp rates required for advanced solar cell metallization.

Whether you need to optimize your peak temperature profiles or scale up production with reliable high-temp furnaces, our team is ready to support your unique manufacturing needs.

Contact KINTEK today to optimize your production line

Visual Guide

References

- Thais Crestani, João Victor Zanatta Britto. Optimization of the Boron Back Surface Field Produced with Reduced Thermal Steps in Bifacial PERT Solar Cell. DOI: 10.3390/en18092347

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does the recycling of CRT slag as a flux benefit PCB smelting? Boost Metal Recovery Efficiency

- What types of materials can a batch furnace handle? Discover Versatile Heat Treatment Solutions

- Why is achieving process pressure within defined time important? Boost Efficiency, Quality, and Safety

- Why is a two-stage heat treatment required for Ca2Fe2O5? Optimize Your Brownmillerite Synthesis

- What is the purpose of using an industrial-grade oven for segmented drying? Optimize Electrode Integrity & Adhesion

- How does a high-temperature TOC analyzer assess RCM NSs performance? Verify Mineralization vs Decolorization

- How does a constant temperature drying oven facilitate solvent removal? Optimize Perovskite Nanocrystal Synthesis

- What is quenching, and why is it important? Achieve Superior Material Hardness and Strength