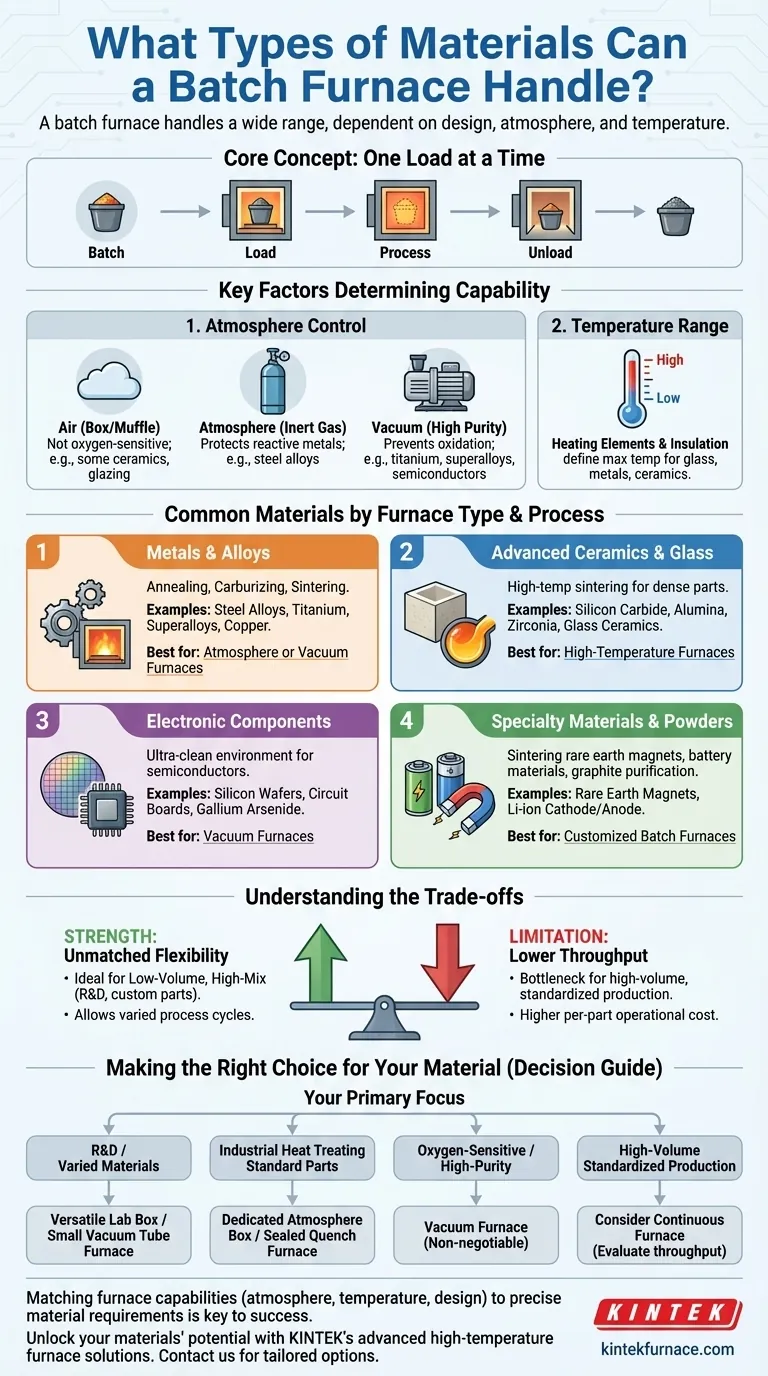

In short, a batch furnace can handle an extremely wide range of materials, but the specific type of material depends entirely on the furnace's design. The most common categories include metals and alloys (from steel to titanium), advanced ceramics, electronic components, glass, and various specialty powders and composite materials.

The term "batch furnace" describes an operational method—processing materials one discrete load at a time—not a specific technology. The furnace's atmosphere control (air, inert gas, or vacuum) and temperature range are the true factors that determine which materials it can safely and effectively process.

What Defines a Batch Furnace's Capability?

To understand what a batch furnace can handle, you must first understand that it is a broad category. A dental furnace is a type of batch furnace, as is a massive industrial vacuum furnace. Their capabilities are dictated by their specific engineering.

The Core Concept: One Load at a Time

A batch furnace processes a single, finite load of material from start to finish. This is in contrast to a continuous furnace, where material is constantly fed through different temperature zones. This batch-style operation makes them exceptionally flexible.

Key Factor 1: Atmosphere Control

The atmosphere inside the furnace is the most critical variable. It prevents unwanted chemical reactions, like oxidation, at high temperatures.

- Air Furnaces (Box/Muffle): These are the simplest type and are suitable for materials that are not sensitive to oxygen, such as some ceramics for glazing or metals for certain heat treatments.

- Atmosphere Furnaces: These use a controlled atmosphere of inert gases (like argon or nitrogen) to protect the material. They are essential for processing most steel alloys and other reactive metals.

- Vacuum Furnaces: These remove the atmosphere almost entirely. They provide the highest level of purity and are required for processing highly reactive materials like titanium, superalloys, advanced ceramics, and semiconductor components.

Key Factor 2: Temperature Range

Different materials require vastly different processing temperatures. A furnace's heating elements and insulation determine its maximum operating temperature, which in turn dictates its suitability for materials like glass, specific metal alloys, or high-purity ceramics.

Common Materials by Furnace Type

With the principles of atmosphere and temperature in mind, we can map materials to the batch furnaces designed to handle them.

Metals and Alloys

Batch furnaces are a cornerstone of metallurgy. They handle everything from common steel to exotic alloys.

Processes include annealing, carburizing (hardening), tempering, and sintering of metal powders. Materials processed include steel alloys, stainless steel, copper and titanium alloys, and superalloys. Vacuum furnaces are essential for oxygen-sensitive metals.

Advanced Ceramics and Glass

The high temperatures required for sintering make batch furnaces ideal for producing dense, high-strength ceramic parts.

This category includes materials like silicon carbide, silicon nitride, alumina, and zirconia blocks used in dental and industrial applications. They are also used for processing glass ceramics and applying glazes.

Electronic Components and Semiconductors

The need for an ultra-clean, controlled environment makes vacuum batch furnaces critical in the electronics industry.

They are used for processing silicon wafers, gallium arsenide, circuit boards, and other semiconductor materials where even microscopic contamination can cause component failure.

Specialty Materials and Powders

The flexibility of batch processing lends itself to a wide array of specialized applications.

This includes sintering rare earth magnets, processing cathode/anode materials for lithium batteries, purifying graphite, and even recycling materials like battery scraps or refining dross in specialized rotary batch furnaces.

Understanding the Trade-offs

Choosing a batch furnace involves clear trade-offs, primarily when compared to continuous systems.

The Strength: Unmatched Flexibility

Batch furnaces are ideal for low-volume, high-mix production. They allow you to run different materials with different process cycles one after another, making them perfect for research and development, custom parts, or applications requiring very long cycle times, such as deep case carburizing.

The Limitation: Lower Throughput

For high-volume manufacturing of a single, standardized part, a batch furnace can become a bottleneck. Its throughput is inherently limited by the time it takes to load, process, cool, and unload a single batch.

The Cost Consideration

Generally, a batch furnace has a lower initial capital investment than a comparable continuous furnace. However, its operational cost per part can be higher due to less efficient energy use and more manual interaction compared to a fully automated continuous line.

Making the Right Choice for Your Material

The decision is not about whether to use a "batch furnace," but which specific type of batch furnace matches your material and process.

- If your primary focus is R&D or processing varied materials: A versatile laboratory box furnace or a small vacuum tube furnace offers the greatest operational flexibility.

- If your primary focus is industrial heat treating of standard steel parts: A dedicated atmosphere box furnace or a sealed quench furnace is the industry standard.

- If your primary focus is processing oxygen-sensitive or high-purity materials: A vacuum furnace is non-negotiable to prevent oxidation and ensure the final integrity of materials like titanium, superalloys, or advanced ceramics.

- If your primary focus is high-volume, standardized production: You should first evaluate if a continuous furnace, rather than a batch furnace, is a better fit for your throughput goals.

Ultimately, matching the furnace's specific capabilities—atmosphere, temperature, and design—to your material's precise requirements is the key to successful thermal processing.

Summary Table:

| Material Category | Common Examples | Suitable Furnace Type |

|---|---|---|

| Metals and Alloys | Steel, Titanium, Superalloys | Atmosphere or Vacuum Furnaces |

| Advanced Ceramics | Silicon Carbide, Alumina | High-Temperature Furnaces |

| Electronic Components | Silicon Wafers, Semiconductors | Vacuum Furnaces |

| Specialty Materials | Rare Earth Magnets, Battery Materials | Customized Batch Furnaces |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your thermal processing goals!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does the quartz tube furnace minimize heat loss? Double Insulation for Energy Efficiency

- What is the use of a quartz tube furnace? For High-Purity, Observable Material Processing

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials