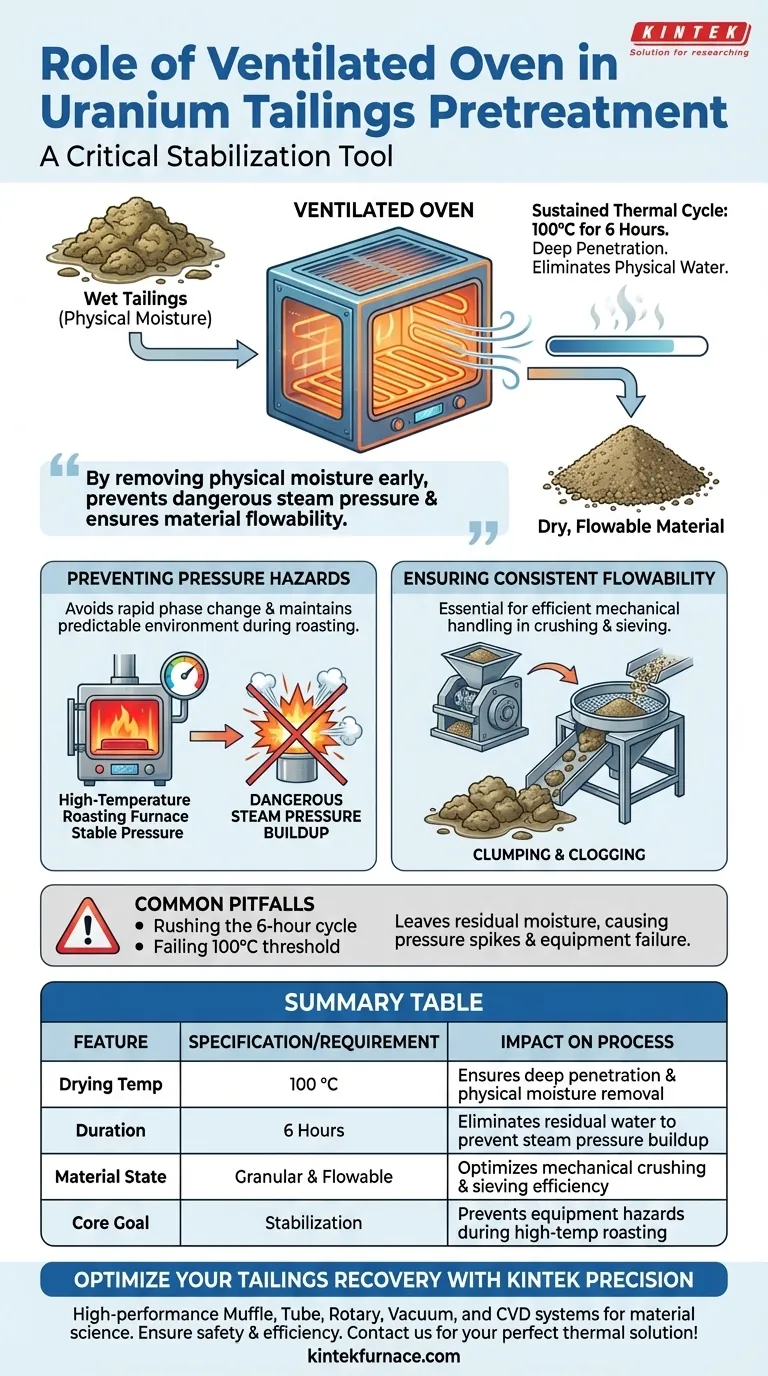

A ventilated oven serves as a critical stabilization tool in the pretreatment of uranium tailings. Its primary function is to perform deep drying of raw materials at a sustained temperature of 100 °C for approximately six hours, effectively eliminating physical moisture from the ore prior to high-temperature processing.

By removing physical moisture early, this pretreatment step prevents dangerous steam pressure buildup during subsequent roasting and ensures the material remains loose and flowable for mechanical crushing.

The Mechanics of Moisture Removal

Achieving Deep Drying

The process is not merely about surface evaporation; it requires a sustained thermal cycle. By operating at 100 °C for six hours, the ventilated oven ensures that heat penetrates the bulk of the material.

Targeting Physical Moisture

The primary target of this phase is physical water trapped within the ore. Removing this water is a prerequisite for downstream chemical processes, specifically chlorination roasting.

Why Moisture Control Matters

Preventing Pressure Hazards

If moisture is left in the tailings, it converts to steam when introduced to high-temperature roasting environments.

This rapid phase change can generate unnecessary steam pressure. Eliminating water in the oven maintains a stable, predictable pressure environment during the volatile roasting phase.

Ensuring Consistent Flowability

Wet tailings tend to clump and adhere to machinery.

Drying the material ensures it maintains consistent flowability. This dry, granular state is essential for efficient mechanical handling, specifically during the crushing and sieving stages that follow.

Common Pitfalls in Pretreatment

The Risks of Incomplete Drying

It is a common error to rush the drying phase to save time.

However, failing to meet the six-hour benchmark or the 100 °C threshold can leave residual moisture in the ore core. This results in the exact issues the oven is meant to prevent: pressure spikes during roasting and equipment clogging during sieving.

Optimizing the Pretreatment Phase

To ensure the success of your uranium tailings recovery process, align your drying strategy with your downstream requirements:

- If your primary focus is Process Safety: Adhere strictly to the full six-hour cycle to eliminate moisture that could cause dangerous pressure variances during chlorination roasting.

- If your primary focus is Material Handling: Ensure the temperature remains consistent at 100 °C to guarantee the ore is brittle and flowable for uniform crushing.

Proper drying is not just a preliminary step; it is the control variable that secures the stability of the entire recovery operation.

Summary Table:

| Feature | Specification/Requirement | Impact on Process |

|---|---|---|

| Drying Temp | 100 °C | Ensures deep penetration and physical moisture removal |

| Duration | 6 Hours | Eliminates residual water to prevent steam pressure buildup |

| Material State | Granular & Flowable | Optimizes mechanical crushing and sieving efficiency |

| Core Goal | Stabilization | Prevents equipment hazards during high-temp roasting |

Optimize Your Tailings Recovery with KINTEK Precision

Don't let residual moisture compromise your lab safety or processing efficiency. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigorous demands of material science.

Whether you require standard ventilated ovens or customizable high-temp furnaces tailored to your unique pretreatment needs, our engineering team is ready to assist. Ensure the stability of your roasting operations today—contact us now to find your perfect thermal solution!

Visual Guide

References

- Jinming Hu, Fangdong Zou. Low-Temperature Chlorination-Roasting–Acid-Leaching Uranium Process of Uranium Tailings: Comparison Between Microwave Roasting and Conventional Roasting. DOI: 10.3390/pr13010082

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a glove box necessary for aluminum foil pre-lithiation? Ensure Purity in Anode Development

- What role do high-temp furnaces play in co-firing SOFCs? Master Ceramic Densification and Sintering

- Why is substrate preheating typically employed during the LPBF process? Minimize Stress & Prevent Cracks in 3D Printing

- What are the process advantages of using solution impregnation for PtS/Ti3C2Tx? Superior In-Situ Growth vs. Mixing

- How do surface oxidation systems improve the interface performance of graphitized fibers? Maximize Composite Strength

- How is temperature regulated in laboratory furnaces? Master Precision Control for Reliable Results

- Why is calcination at 700 °C necessary for extracted diatomaceous biosilica? Achieve Peak Material Stability

- What is the purpose of high-purity argon in Fe60Co10-xNi15Cr15Six alloy preparation? Ensure Purity for Laser Cladding