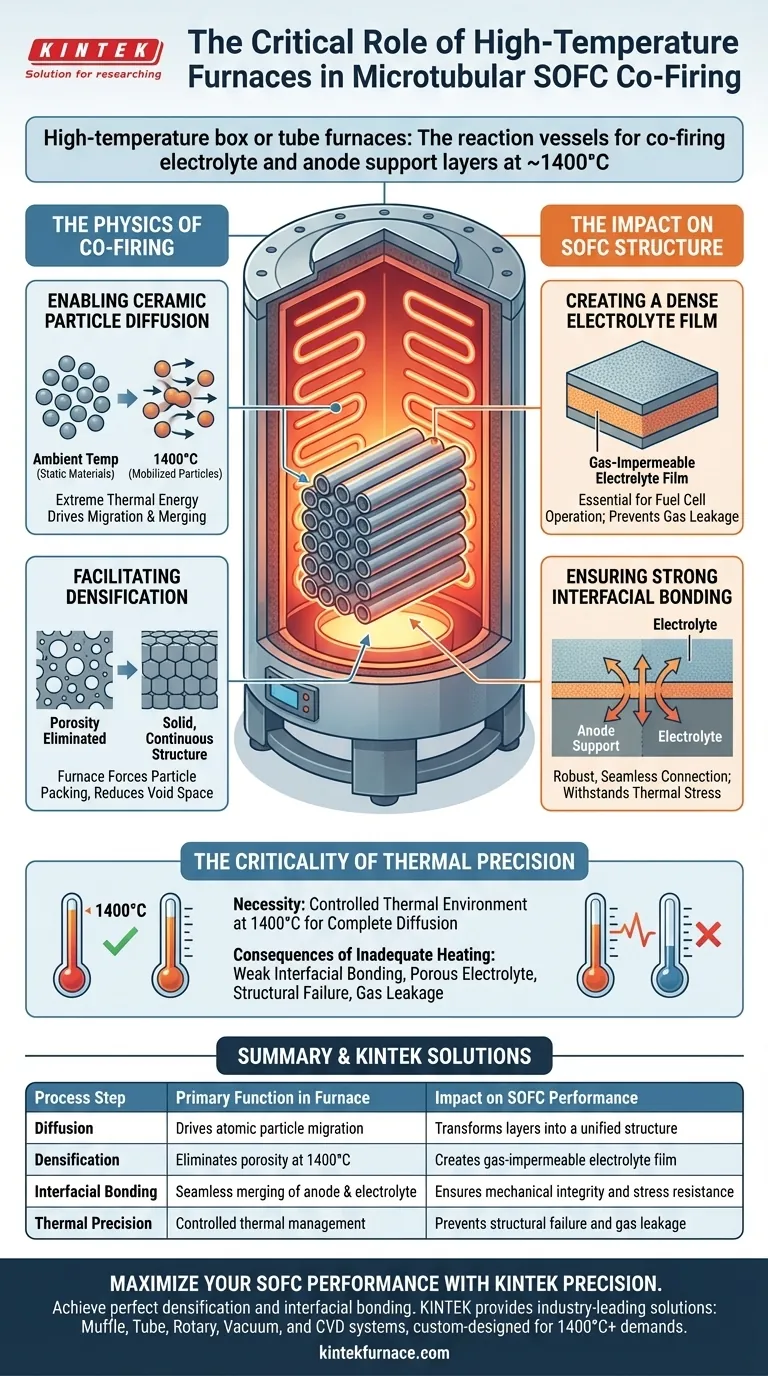

High-temperature box or tube furnaces serve as the critical reaction vessel for co-firing the electrolyte and anode support layers of microtubular Solid Oxide Fuel Cells (SOFCs). They provide a highly controlled thermal environment, typically reaching temperatures around 1400 °C, which is necessary to simultaneously sinter these distinct ceramic layers into a unified component.

The furnace enables ceramic particle diffusion and densification, transforming separate material layers into a unified, high-performance core structure with a dense electrolyte film and strong interfacial bonds.

The Physics of Co-Firing

Enabling Ceramic Particle Diffusion

The primary function of the furnace is to drive ceramic particle diffusion.

At ambient temperatures, the materials in the anode and electrolyte are static. The furnace provides the extreme thermal energy required to mobilize these particles at the atomic level, allowing them to migrate and merge.

Facilitating Densification

Alongside diffusion, the furnace drives the process of densification.

This mechanism eliminates porosity within the ceramic layers. By holding the materials at high temperatures (e.g., 1400 °C), the furnace forces the particles to pack tightly together, reducing void space and creating a solid, continuous structure.

The Impact on SOFC Structure

Creating a Dense Electrolyte Film

The ultimate goal of the co-firing process is to produce a dense electrolyte film.

The furnace ensures that the electrolyte layer becomes impermeable to gas, which is a fundamental requirement for the fuel cell's operation. Without the specific heat profile provided by the furnace, the film would remain porous and ineffective.

Ensuring Strong Interfacial Bonding

The furnace is responsible for the mechanical integrity of the cell through interfacial bonding.

Because the anode support and electrolyte are fired together (co-fired), the diffusion process occurs across the boundary between them. This creates a robust, seamless connection between layers, ensuring the core structure can withstand thermal stress and operation.

The Criticality of Thermal Precision

The Necessity of Controlled Environments

The primary reference highlights that these furnaces must provide a controlled thermal environment, not just raw heat.

If the temperature fluctuates or fails to reach the target (e.g., 1400 °C), the diffusion process will be incomplete.

Consequences of Inadequate Heating

Failure to maintain this precise environment compromises the entire cell.

Insufficient heat results in weak interfacial bonding and a porous electrolyte. This leads to structural failure or gas leakage, rendering the SOFC incapable of high-performance operation.

Making the Right Choice for Your Goal

To achieve a functional microtubular SOFC, the furnace selection must align with the specific material requirements of your ceramic layers.

- If your primary focus is structural integrity: Ensure your furnace can maintain stable temperatures at 1400 °C to guarantee strong interfacial bonding between the anode and electrolyte.

- If your primary focus is electrochemical performance: Prioritize a furnace with precise thermal control to ensure complete densification of the electrolyte film, preventing gas crossover.

The success of the co-firing process relies entirely on the furnace's ability to facilitate particle diffusion through precise thermal management.

Summary Table:

| Process Step | Primary Function in Furnace | Impact on SOFC Performance |

|---|---|---|

| Diffusion | Drives atomic particle migration | Transforms layers into a unified structure |

| Densification | Eliminates porosity at 1400°C | Creates gas-impermeable electrolyte film |

| Interfacial Bonding | Seamless merging of anode & electrolyte | Ensures mechanical integrity and stress resistance |

| Thermal Precision | Controlled thermal management | Prevents structural failure and gas leakage |

Maximize Your SOFC Performance with KINTEK Precision

Achieving perfect densification and interfacial bonding in microtubular Solid Oxide Fuel Cells requires unmatched thermal stability. KINTEK provides industry-leading high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to meet the rigorous 1400°C+ demands of ceramic co-firing. Backed by expert R&D and manufacturing, our systems are fully customizable to your specific laboratory or production needs.

Ready to elevate your fuel cell research? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Dhruba Panthi, Hai Feng. Extreme Thermal Cycling of Anode‐Supported Microtubular Solid Oxide Fuel Cells Using a Novel Test Setup. DOI: 10.1002/aesr.202500119

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why are DEZ and GEME selected for Ge:ZnO ALD? Unlock Precise Atomic Doping and Thermal Stability

- Why is an electric blast drying oven required for CRP microstructure analysis? Ensure Data Accuracy with Proper Drying

- What are some common applications of laboratory furnaces? Unlock Precision in Material Transformation

- What role does industrial heating equipment play in the manufacturing process of 55Si2 spring steel during winding?

- Why is high temperature control precision essential for SiC/SiC composites? Master Microstructural Engineering

- What is the function of industrial furnaces in 7075 aluminum solution treatment? Master Material Strength

- What is the purpose of performing a 600 degree Celsius annealing treatment? Enhance AZO Thin Film Stability

- What is the necessity of the subsequent pyrolysis step in ZnS-CFC preparation? Unlocking High-Performance Carbonization