The temperature of the annealing process acts as a critical tuning mechanism for the optical properties of zinc selenide (ZnSe) nanocrystals. By adjusting thermal activation between 800°C and 1000°C, you directly manipulate photoluminescence (PL) intensity and spectral width through the elimination of point defects and the induction of atomic rearrangement.

The control of luminescence in ZnSe nanocrystals is a balancing act between structural repair and chemical stability. While high temperatures heal physical defects to improve crystal quality, they also induce Selenium loss, creating non-stoichiometric shifts that alter specific emission bands.

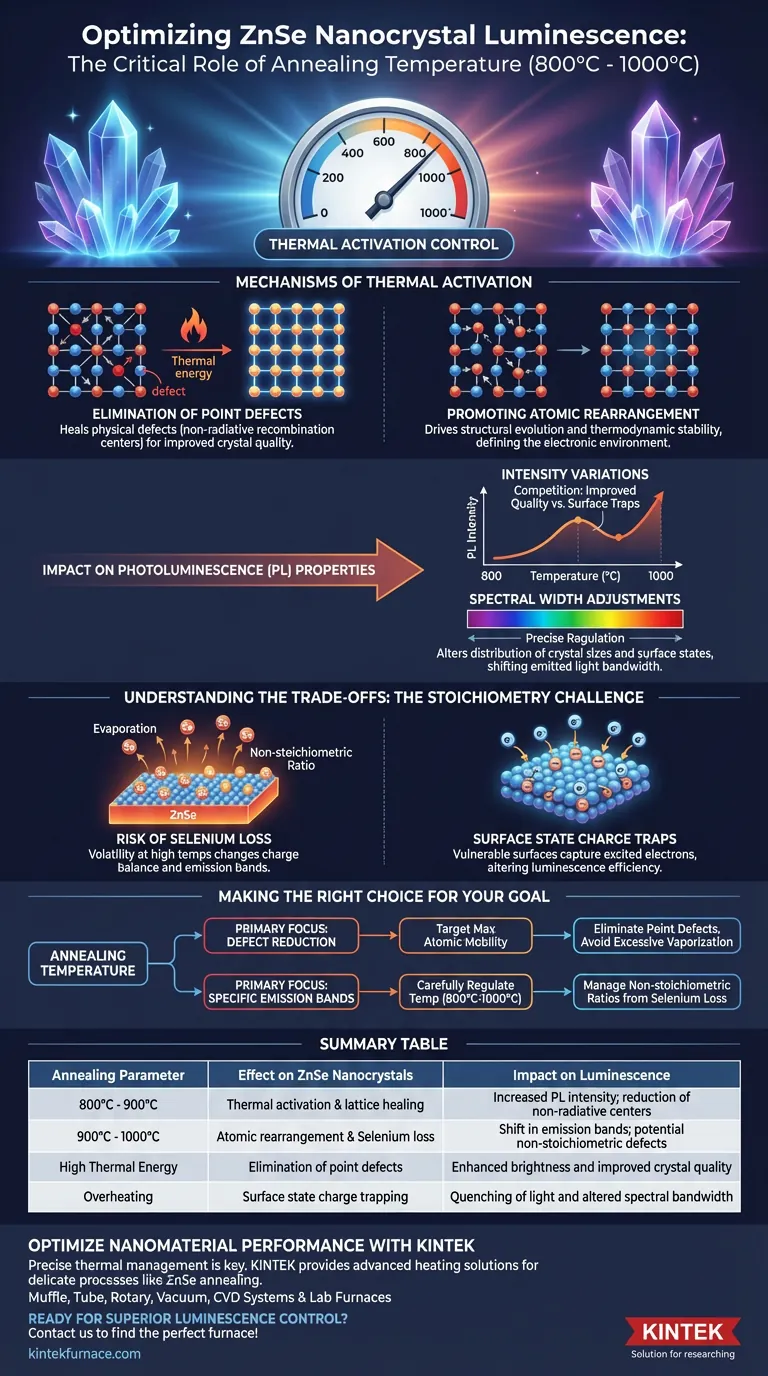

The Mechanisms of Thermal Activation

Elimination of Point Defects

The primary function of high-temperature annealing is thermal activation.

At elevated temperatures, the thermal energy supplied to the nanocrystals is sufficient to mobilize atoms within the lattice.

This mobility allows the material to "heal" itself, effectively removing point defects that often act as non-radiative recombination centers, which would otherwise quench luminescence.

Promoting Atomic Rearrangement

Beyond simple defect repair, annealing drives significant structural evolution.

The process promotes atomic rearrangement, allowing the crystal lattice to settle into a more thermodynamically stable state.

This structural relaxation is essential for defining the final electronic environment of the nanocrystal, which dictates how it interacts with light.

Impact on Photoluminescence (PL) Properties

Intensity Variations

As the annealing temperature increases from 800°C to 1000°C, the intensity of the photoluminescence changes efficiently.

This fluctuation is not linear; it reflects the competition between improved crystal quality (which boosts brightness) and surface trap formation (which can reduce it).

Spectral Width Adjustments

Temperature control allows for the precise regulation of the spectral width of the emission.

Changes in the annealing temperature alter the distribution of crystal sizes and surface states.

Consequently, the "color" or bandwidth of the emitted light shifts, allowing you to tune the material for specific optical applications.

Understanding the Trade-offs: The Stoichiometry Challenge

The Risk of Selenium Loss

A critical side effect of high-temperature annealing in ZnSe is the volatility of Selenium.

As temperatures approach 1000°C, the material is prone to losing Selenium atoms, leading to a non-stoichiometric chemical ratio.

This loss changes the charge balance within the crystal, directly impacting the emission bands and potentially introducing new, unwanted defect states.

Surface State Charge Traps

While internal defects may be healed, the surface of the nanocrystal remains vulnerable.

The annealing process modifies surface state charge trapping centers.

If not controlled, these traps can capture excited electrons before they emit light, altering the efficiency and character of the luminescence.

Making the Right Choice for Your Goal

To optimize the luminescence of ZnSe nanocrystals, you must select an annealing temperature that aligns with your specific optical requirements.

- If your primary focus is defect reduction: Target temperatures that maximize atomic mobility to eliminate point defects without inducing excessive vaporization.

- If your primary focus is specific emission bands: Carefully regulate the temperature between 800°C and 1000°C to manage the non-stoichiometric ratios caused by Selenium loss.

Precise thermal management is the difference between a high-performing optical component and a chemically unstable material.

Summary Table:

| Annealing Parameter | Effect on ZnSe Nanocrystals | Impact on Luminescence |

|---|---|---|

| 800°C - 900°C | Thermal activation & lattice healing | Increased PL intensity; reduction of non-radiative centers |

| 900°C - 1000°C | Atomic rearrangement & Selenium loss | Shift in emission bands; potential non-stoichiometric defects |

| High Thermal Energy | Elimination of point defects | Enhanced brightness and improved crystal quality |

| Overheating | Surface state charge trapping | Quenching of light and altered spectral bandwidth |

Optimize Your Nanomaterial Performance with KINTEK

Precise thermal management is the difference between high-performing optical components and chemical instability. KINTEK provides the advanced heating solutions required to master delicate processes like ZnSe annealing.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to meet your unique research or production needs.

Ready to achieve superior luminescence control? Contact us today to find the perfect furnace for your lab!

Visual Guide

References

- Aiman Akylbekovа, А. Usseinov. RAMAN ANALYSIS OF NANOCRYSTALS BASED ON ZINC SELENIDE. DOI: 10.52676/1729-7885-2023-4-77-84

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- What are some examples of high-temperature industrial heating processes? Explore Key Applications and Benefits

- Why is a high-precision heating/cooling stage important for 2D In2Se3 studies? Secure Precise Phase Transition Data

- What function does a high-temperature furnace serve in alumina nanopowder decarbonization? Ensure Purity & Performance

- What are the benefits of ESR for carbonitride distribution in H13 steel? Enhance Your Material's Isotropic Properties

- Why is a nitrogen (N2) purging system necessary for biomass torrefaction? Prevent Combustion and Maximize Biochar Yield

- What is the role of sintering in CsPbBr3-SiO2 preparation? Unlock Ultra-Stability with Precise Thermal Sealing

- How does DTA contribute to determining processing parameters for Ge-Se-Tl-Sb alloys? Optimize Your Thermal Analysis

- How does environmental control equipment assist in assessing CMS membranes? Unlock Precision in Physical Aging Tests