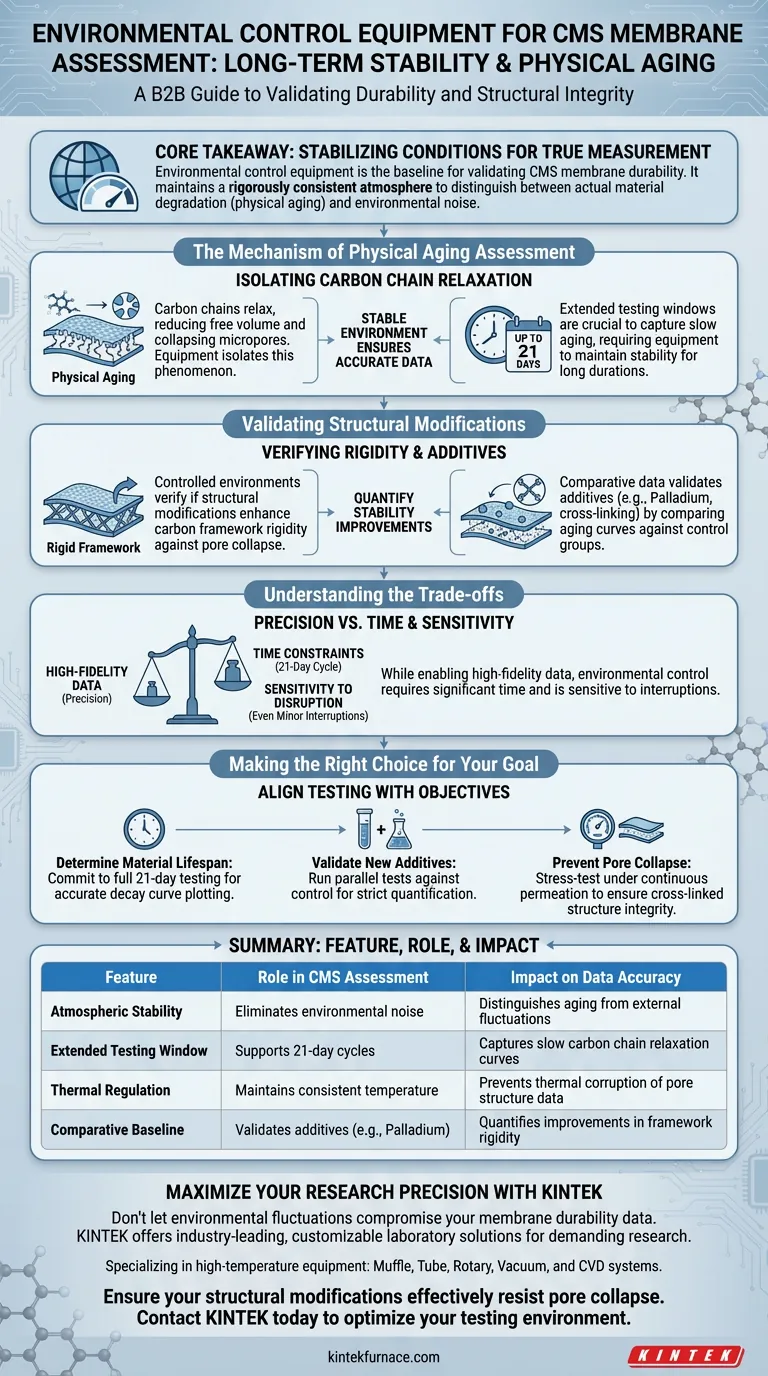

Environmental control equipment acts as the fundamental baseline for validating the durability of Carbon Molecular Sieve (CMS) membranes. By maintaining a rigorously consistent atmosphere over extended periods, this equipment allows researchers to distinguish between actual material degradation and environmental noise. It specifically enables the measurement of "physical aging," ensuring that performance data reflects the true long-term stability of the carbon framework.

Core Takeaway Physical aging—the natural decay of performance due to carbon chain relaxation—cannot be accurately measured in fluctuating environments. Environmental control equipment stabilizes the testing conditions, allowing you to definitively verify if structural enhancements, such as cross-linking or palladium integration, are successfully resisting pore collapse.

The Mechanism of Physical Aging Assessment

Isolating Carbon Chain Relaxation

Physical aging is the primary adversary of long-term membrane performance. It occurs because the carbon chains within the membrane tend to relax over time, moving toward a state of equilibrium.

This relaxation leads to a reduction in free volume and the collapse of micropores. Environmental control equipment is essential here because it isolates this specific phenomenon, ensuring that observed changes in permeation are caused by this structural relaxation rather than external variables.

The Necessity of Extended Testing Windows

Physical aging is a slow process that does not manifest immediately. To capture accurate data, testing must occur over extended durations, often lasting up to 21 days.

Without environmental control equipment to maintain stability for these long durations, thermal or atmospheric fluctuations would corrupt the data. The equipment ensures that the conditions at hour 1 are identical to the conditions at hour 500.

Validating Structural Modifications

Verifying Rigidity and Pore Stability

The ultimate goal of CMS development is to create a rigid carbon framework that resists aging. Researchers often introduce structural modifications to achieve this.

Controlled testing environments are used to verify if these modifications effectively enhance the rigidity of the carbon framework. By subjecting the membrane to consistent long-term stress, the equipment reveals whether the pore structure remains open or succumbs to collapse.

Assessing the Impact of Additives

To combat aging, specific elements like palladium or cross-linked structures are often introduced into the precursor.

Environmental control equipment provides the comparative data needed to validate these additions. By comparing the aging curves of modified vs. unmodified membranes under identical controlled conditions, you can quantify exactly how much stability the additives provide.

Understanding the Trade-offs

The Cost of Precision

While environmental control enables high-fidelity data, it introduces significant time constraints. Because physical aging is a gradual process, the equipment must be committed to a single sample for weeks (e.g., the 21-day cycle).

Sensitivity to Disruption

The reliability of this assessment is entirely dependent on the continuity of the environment. Even minor interruptions in temperature or gas flow during the testing period can invalidate the long-term data set, requiring the test to restart from zero.

Making the Right Choice for Your Goal

To effectively utilize environmental control equipment for CMS assessment, align your testing protocols with your specific development objectives:

- If your primary focus is determining material lifespan: Commit to the full 21-day testing cycle to accurately plot the decay curve caused by carbon chain relaxation.

- If your primary focus is validating new additives (e.g., Palladium): Use the equipment to run parallel tests against a control group to strictly quantify the increase in framework rigidity.

- If your primary focus is preventing pore collapse: Utilize the equipment to stress-test the membrane under continuous permeation to ensure the cross-linked structures hold up over time.

True stability assessment requires patience; only by controlling the environment can you see the reality of the material.

Summary Table:

| Feature | Role in CMS Assessment | Impact on Data Accuracy |

|---|---|---|

| Atmospheric Stability | Eliminates environmental noise | Distinguishes aging from external fluctuations |

| Extended Testing Window | Supports 21-day cycles | Captures slow carbon chain relaxation curves |

| Thermal Regulation | Maintains consistent temperature | Prevents thermal corruption of pore structure data |

| Comparative Baseline | Validates additives (e.g., Palladium) | Quantifies improvements in framework rigidity |

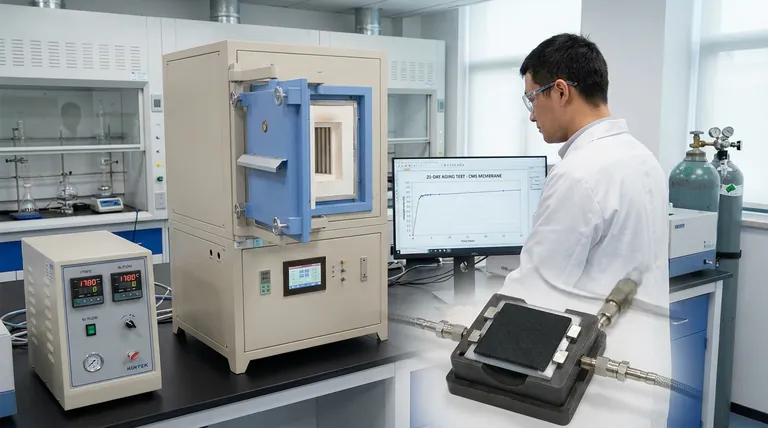

Maximize Your Research Precision with KINTEK

Don't let environmental fluctuations compromise your membrane durability data. KINTEK provides industry-leading laboratory solutions tailored for the most demanding research applications. Backed by expert R&D and manufacturing, we offer a comprehensive range of high-temperature equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which are fully customizable to meet your unique carbon research needs.

Ensure your structural modifications effectively resist pore collapse with equipment designed for stability and longevity. Contact KINTEK today to optimize your testing environment and achieve the high-fidelity results your project deserves.

Visual Guide

References

- Cascade Promotion of Gas Separation Performances in CMS Membranes: MOFs With Functional Groups and Loaded Noble Metals. DOI: 10.1002/advs.202503471

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How does a constant temperature and humidity curing chamber contribute to GCCM hydration? Optimize Material Strength

- What is the primary role of a ball mill in raw material preparation for vacuum carbothermic reduction of magnesium? Ensure a Complete and Rapid Reaction

- What role does a high-power graphite resistance furnace play in SiC ceramic treatment? Achieve Perfect Crystallization

- How does the heat treatment of NC6 (1.2063) tool steel affect its performance? Key SPIF Tool Optimization

- What is the purpose of using an Argon (Ar 5.0) protective atmosphere? Ensure Oxidation-Free Cooling

- What is the primary function of multi-stage oxidation ovens? Secure High-Strength Carbon Fiber Stabilization

- What is the main benefit of using a benchtop industrial oven? Save Space and Boost Efficiency in Your Lab

- How does an oil circulation heating and cooling system affect HPDC? Optimize Your Die Casting Thermal Control