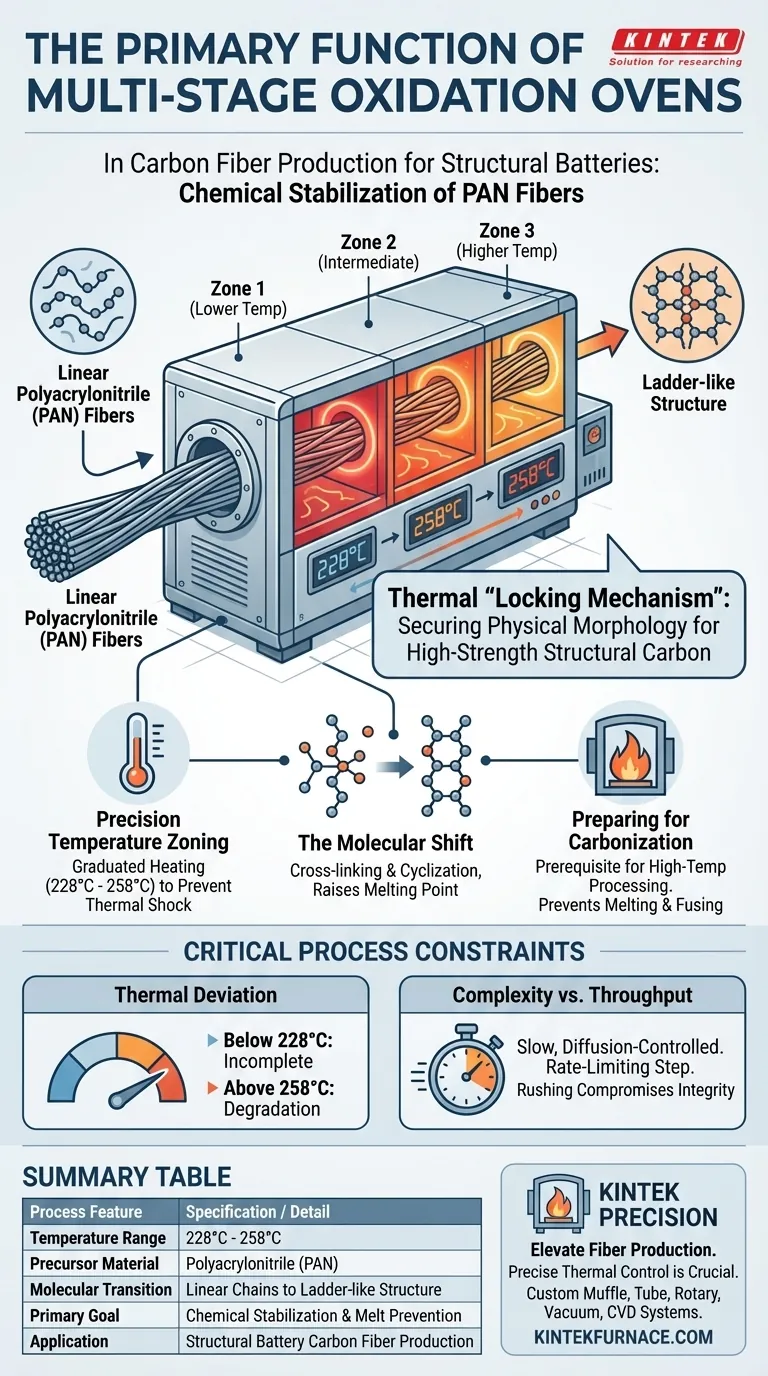

The primary function of multi-stage oxidation ovens is to chemically stabilize polyacrylonitrile (PAN) fibers prior to high-temperature processing. By utilizing precisely controlled temperature zones between 228°C and 258°C, these ovens facilitate a critical reaction that converts the fibers' linear molecular chains into a heat-resistant, ladder-like structure. This transformation is essential to prevent the fibers from melting and to ensure they maintain their physical shape during the subsequent carbonization stages required for structural battery components.

Multi-stage oxidation acts as the thermal "locking mechanism" of manufacturing, securing the physical morphology of the fiber so it can survive the transition from a plastic precursor to a high-strength structural carbon.

The Mechanics of Fiber Stabilization

Precision Temperature Zoning

The oxidation process does not rely on a single, static temperature. Instead, it employs multi-stage ovens that maintain specific thermal environments.

The operational window is strictly controlled, typically ranging from 228°C to 258°C. This graduated heating allows for a controlled reaction rate, preventing thermal shock or uneven stabilization across the fiber tow.

The Molecular Shift

The core purpose of this thermal exposure is to alter the atomic arrangement of the polyacrylonitrile (PAN) precursor.

Initially, the PAN molecules exist as linear chains. As they pass through the oxidation ovens, these chains cross-link and cyclize to form a stable, ladder-like structure. This molecular reconfiguration raises the melting point of the material significantly.

Preparing for Carbonization

Without this stabilization phase, the subsequent step—carbonization—would be impossible.

Carbonization involves extremely high temperatures intended to strip away non-carbon atoms. If the fibers were not first treated in the oxidation ovens to achieve a heat-resistant structure, they would simply melt or fuse together, destroying the fibrous morphology necessary for structural reinforcement.

Critical Process Constraints

The Consequence of Thermal Deviation

The tight temperature range (228°C to 258°C) highlighted in standard processing indicates a high sensitivity to thermal fluctuation.

If the temperature drops below the lower threshold, the chemical transformation may remain incomplete, leading to structural failure later. Conversely, exceeding the upper limit risks burning or degrading the fiber before the ladder structure is fully formed.

Complexity vs. Throughput

Achieving this "ladder-like" structure is a slow, diffusion-controlled process compared to other manufacturing steps.

The requirement for precisely controlled zones implies that this stage is often the rate-limiting step in production. Rushing this phase to increase output compromises the integrity of the ladder structure, resulting in fibers that cannot withstand the mechanical loads required in structural batteries.

Making the Right Choice for Your Goal

If your primary focus is process engineering: Ensure your thermal control systems can maintain strict variance limits within the 228°C–258°C window to guarantee uniform stabilization.

If your primary focus is material performance: Prioritize the completeness of the linear-to-ladder molecular conversion, as this directly dictates the fiber's ability to maintain morphology under load.

Mastering the oxidation phase is the only way to ensure the precursor material evolves into a viable structural component.

Summary Table:

| Process Feature | Specification / Detail |

|---|---|

| Temperature Range | 228°C to 258°C |

| Precursor Material | Polyacrylonitrile (PAN) |

| Molecular Transition | Linear chains to ladder-like structure |

| Primary Goal | Chemical stabilization & melt prevention |

| Application | Structural battery carbon fiber production |

Elevate Your Fiber Production with KINTEK Precision

Precise thermal control is the difference between a high-performance structural battery component and material failure. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature lab furnaces.

Our equipment is fully customizable to meet your unique oxidation and carbonization requirements, ensuring your materials achieve the perfect molecular stabilization. Contact us today to optimize your thermal processing workflow.

Visual Guide

References

- Ruben Tavano, E. Leif. Influence of Carbonisation Temperatures on Multifunctional Properties of Carbon Fibres for Structural Battery Applications. DOI: 10.1002/batt.202400110

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is the purpose of using an industrial-grade drying oven to heat wood samples to 103 °C? Enhance Resin Impregnation

- Why is hydrothermal synthesis utilized for the production of ZIF-8? Control Nanocrystal Purity and Uniformity

- Why specific constant temperature holding times for NbC and Cr7C3? Achieve Stoichiometric Precision in Lab Synthesis

- What is the significance of calculating AC impedance in the power control of indirect heating resistance furnaces?

- What is the temperature range of a lab furnace? Find Your Perfect Match

- What is the function of a vacuum drying oven in the post-treatment of PPy/alpha-Fe2O3 composite materials? Expert Insights

- Why is a 1:1 mixture of NaNO3 and KNO3 used in molten salt baths? Optimize Quenching Performance

- What is the necessity of carbon coating for silicon anodes? Engineering Durability for High-Performance Batteries