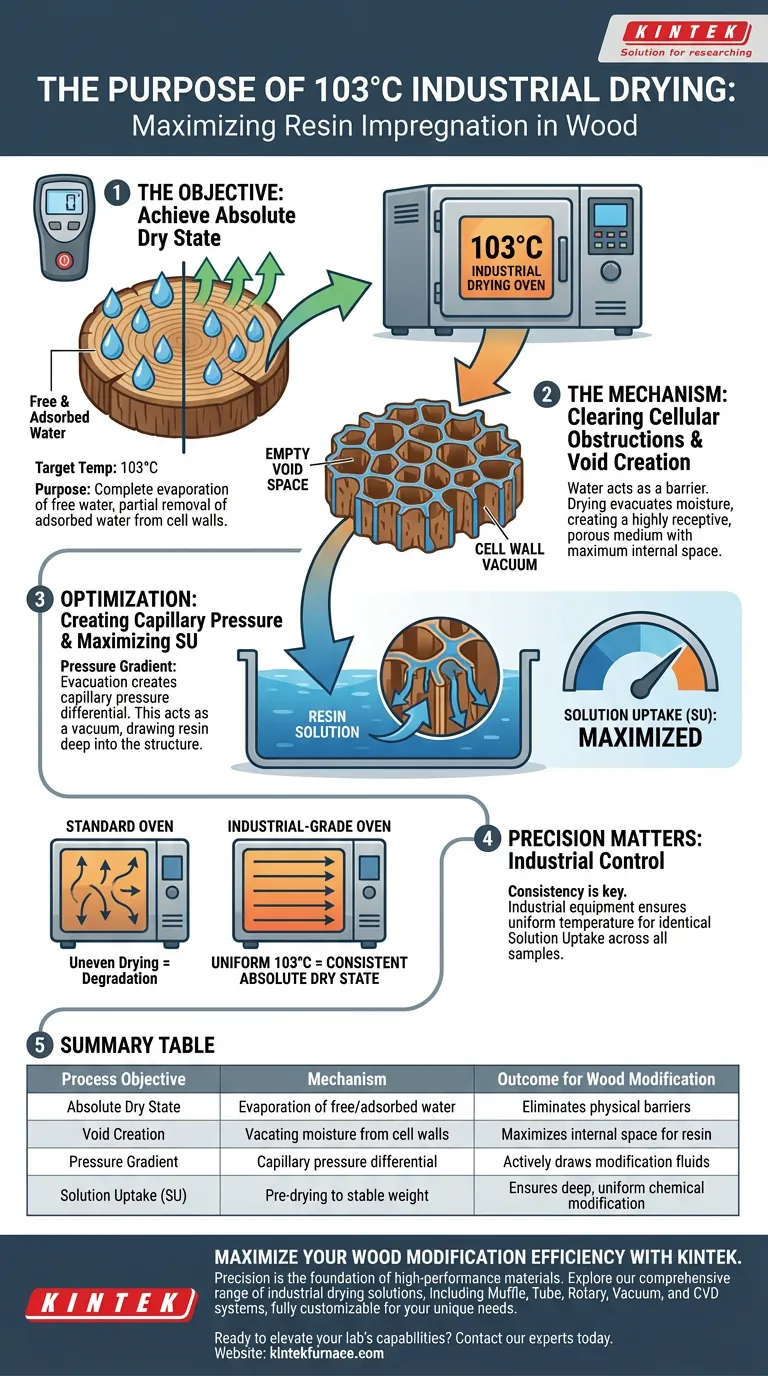

The primary purpose of heating wood samples to 103 °C using an industrial-grade drying oven is to eliminate moisture barriers and prepare the cellular structure for deep chemical modification. By thoroughly removing both free water and a significant portion of adsorbed water from the cell cavities and walls, the wood reaches an absolute dry state. This evacuation creates maximum internal void space and establishes a capillary pressure differential that actively draws resin solutions into the material during the subsequent impregnation phase.

Core Takeaway Achieving an "absolute dry state" is not merely about removing wetness; it is about mechanically emptying the cellular infrastructure. By vacating water from the cell walls, you create a physical void and a pressure gradient that acts as a vacuum, essential for maximizing Solution Uptake (SU) and ensuring resins penetrate deep into the wood's microscopic structure.

The Physics of Moisture Removal

Achieving the Absolute Dry State

The target temperature of 103 °C is specific and critical. At this threshold, the oven ensures the complete evaporation of free water (liquid water in cell cavities) and forces out a portion of the adsorbed water (water bound within the cell walls).

Clearing Cellular Obstructions

Water within wood acts as a physical barrier. If cell cavities or walls remain occupied by moisture, there is no physical space for the modification fluid to enter.

By driving this moisture out, the drying process converts the wood into a highly receptive, porous medium ready for saturation.

Optimizing for Resin Impregnation

Creating Capillary Pressure Differentials

The drying process does more than just open space; it creates a driver for flow. The evacuation of water creates a capillary pressure differential between the empty porous wood and the external environment.

When the dry wood is submerged in the resin solution, this pressure difference facilitates the rapid and deep entry of the fluid into the wood structure.

Maximizing Solution Uptake (SU)

The ultimate metric for this preparation step is Solution Uptake (SU). Without the 103 °C drying phase, the resin would only coat the surface or penetrate superficially.

Pre-drying ensures that modifiers can fully penetrate the interior of the wood cell walls, resulting in a thorough and uniform modification rather than a surface-level treatment.

Understanding the Role of Equipment Precision

The Necessity of Industrial Control

While the primary goal at this stage is high-heat drying (103 °C), the use of an industrial-grade oven implies a need for consistency.

Standard ovens may fluctuate, leading to uneven drying where some samples retain moisture while others degrade. Industrial equipment ensures the temperature is uniform across all samples to guarantee the "absolute dry" baseline.

Distinguishing Process Stages

It is vital to distinguish this preparation stage from later processing steps. While 103 °C is used for pre-impregnation drying, lower controlled temperatures (such as 80 °C) are often used after impregnation to evaporate solvents without triggering premature resin curing.

The 103 °C phase is purely about void creation, whereas subsequent heating stages focus on chemistry management (preventing premature cross-linking).

Making the Right Choice for Your Goal

To ensure your wood modification process is successful, apply the drying principles based on your specific objectives:

- If your primary focus is deep structural modification: Ensure your samples reach a stable weight at 103 °C to guarantee the total evacuation of free water, maximizing the volume available for resin.

- If your primary focus is process consistency: Use a precision-controlled industrial oven to eliminate temperature gradients, ensuring that every wood sample has identical Solution Uptake potential.

Fundamentally, the 103 °C drying step is not just about dehydration; it is the strategic creation of empty space to enable maximal chemical performance.

Summary Table:

| Process Objective | Mechanism | Outcome for Wood Modification |

|---|---|---|

| Absolute Dry State | Evaporation of free and adsorbed water | Eliminates physical barriers within cell cavities |

| Void Creation | Vacating moisture from cell walls | Maximizes internal space for resin penetration |

| Pressure Gradient | Capillary pressure differential | Actively draws modification fluids into the wood structure |

| Solution Uptake (SU) | Pre-drying to a stable weight | Ensures deep, uniform chemical modification vs. surface coating |

Maximize Your Wood Modification Efficiency with KINTEK

Precision is the foundation of high-performance materials. At KINTEK, we understand that achieving an absolute dry state requires more than just heat—it requires uniformity and reliability.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized lab high-temp furnaces. Our industrial drying solutions are fully customizable to meet your unique research or production needs, ensuring consistent temperature control for optimal Solution Uptake (SU).

Ready to elevate your lab's capabilities? Contact our experts today to find the perfect thermal solution for your wood modification and resin impregnation projects!

Visual Guide

References

- Johannes Karthäuser, Holger Militz. Utilizing pyrolysis cleavage products from softwood kraft lignin as a substitute for phenol in phenol-formaldehyde resins for modifying different wood species. DOI: 10.1007/s00107-024-02056-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the role of high-precision furnaces in Inconel 718 heat treatment? Master Microstructural Engineering

- What is the role of an industrial oven in the drying stage of Rosa roxburghii biochar? Unlock Structural Integrity

- What is the graphite furnace technique? A Guide to Ultra-Trace Metal Analysis

- Why are specific heating pulses applied when monitoring molten metal surface oscillations? Unlock Material Insights

- Why is SF6 gas utilized as the primary inhibitor in AS-ALD on ZrO2? Master Defect-Based Passivation Strategy

- How does a rotary evaporator function in the recovery of crude cottonseed lipids? Optimize Your Lipid Extraction

- What role does a vertical heating furnace play in the production of nano-glass composites? Precision Shaping Experts

- Why is an industrial forced air drying oven required for drying banana slices? Unlock Precision & Nutritional Quality