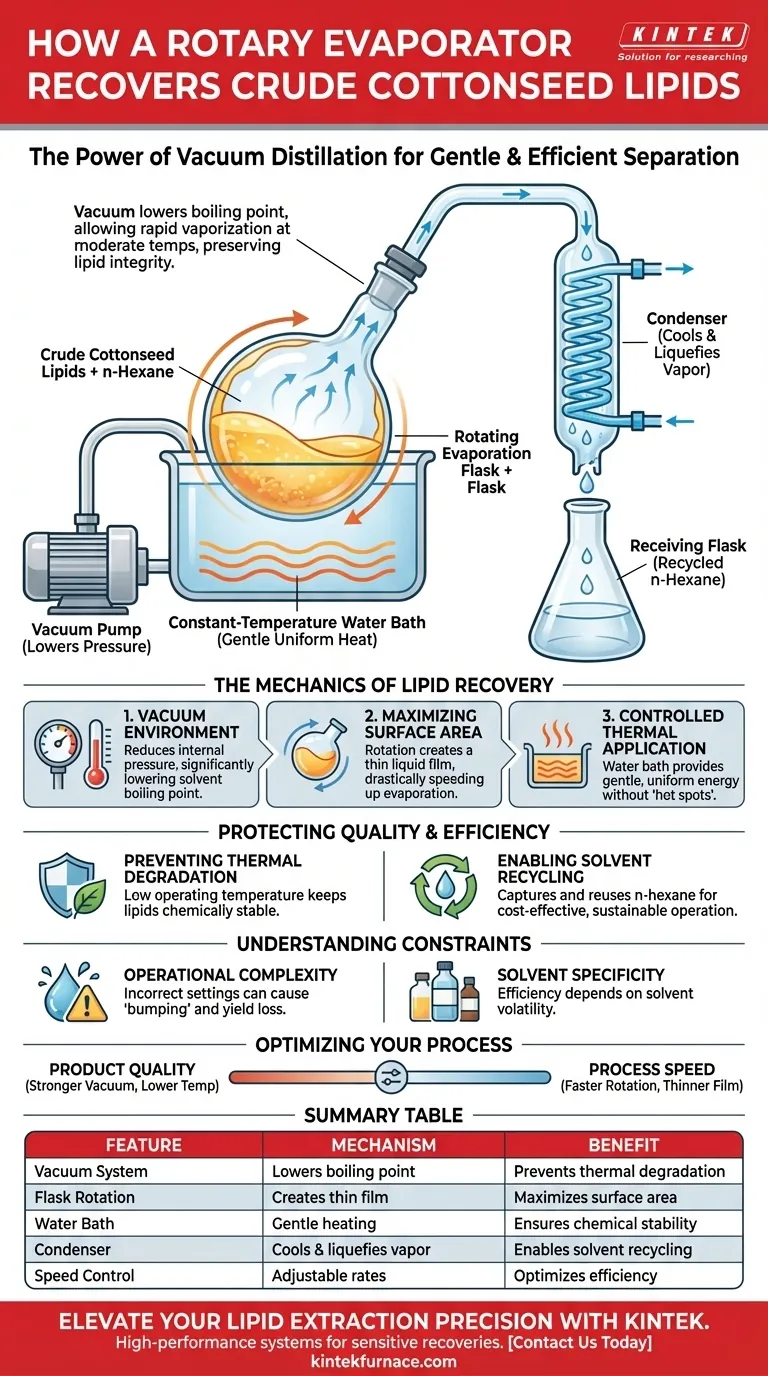

A rotary evaporator facilitates the recovery of crude cottonseed lipids by utilizing vacuum distillation to separate the lipids from the n-hexane solvent. By lowering the pressure within the system, the device reduces the boiling point of the solvent, allowing it to vaporize rapidly at moderate temperatures while the rotation of the flask maximizes the surface area for evaporation.

The primary advantage of this method is the preservation of chemical integrity; it achieves efficient solvent removal without subjecting the heat-sensitive cottonseed lipids to temperatures that cause thermal degradation.

The Mechanics of Lipid Recovery

Creating a Vacuum Environment

The core function of the rotary evaporator in this context is vacuum distillation.

By reducing the internal pressure of the system, the device significantly lowers the boiling point of the n-hexane solvent.

This allows the solvent to transition from liquid to vapor at a much lower temperature than would be required at atmospheric pressure.

Maximizing Surface Area

A crucial component of the process is the rotation of the evaporation flask.

This rotation spreads the crude cottonseed lipid mixture across the inner wall of the flask, creating a thin liquid film.

This significantly increases the surface area exposed to the vacuum, which drastically speeds up the evaporation rate of the solvent.

Controlled Thermal Application

While the vacuum lowers the boiling point, energy is still required to drive the phase change.

A constant-temperature water bath applies gentle, uniform heat to the rotating flask.

This provides the necessary energy for the n-hexane to vaporize without creating "hot spots" that could damage the lipids.

Protecting Quality and Efficiency

Preventing Thermal Degradation

Crude cottonseed lipids are sensitive to high temperatures.

Excessive heat can alter the chemical structure of these lipids, reducing the quality of the final product.

The rotary evaporator mitigates this risk by keeping the operating temperature low, ensuring the lipids remain thermally stable throughout the recovery process.

Enabling Solvent Recycling

The system does not just vent the vaporized solvent; it captures it.

The vaporized n-hexane travels to a condenser where it cools and reverts to liquid form for collection.

This allows for the recycling of the n-hexane, making the extraction process more cost-effective and environmentally sustainable.

Understanding the Constraints

Operational Complexity

While efficient, rotary evaporators require precise balancing of vacuum pressure and water bath temperature.

Incorrect settings can lead to "bumping" (sudden boiling), which may splash the crude lipids into the condenser, causing loss of yield.

Solvent Specificity

This process relies heavily on the volatility of the solvent being used.

While highly effective for volatile solvents like n-hexane, the efficiency drops if the solvent has a very high boiling point or interacts strongly with the lipids.

Optimizing Your Recovery Process

To achieve the best results when recovering cottonseed lipids, consider your specific operational priorities.

- If your primary focus is Product Quality: Prioritize a stronger vacuum to minimize the water bath temperature, ensuring the lowest possible thermal stress on the lipids.

- If your primary focus is Process Speed: Maximize the rotation speed of the flask to create the thinnest possible film, facilitating the fastest possible evaporation rate.

By balancing the vacuum strength with the rotation speed, you ensure a rapid recovery that maintains the chemical integrity of your cottonseed lipids.

Summary Table:

| Feature | Mechanism in Lipid Recovery | Benefit to Process |

|---|---|---|

| Vacuum System | Lowers boiling point of n-hexane | Prevents thermal degradation of sensitive lipids |

| Flask Rotation | Creates a thin liquid film | Maximizes surface area for rapid solvent evaporation |

| Water Bath | Provides gentle, uniform heating | Eliminates hot spots and ensures chemical stability |

| Condenser | Cools and liquefies solvent vapor | Enables cost-effective solvent recycling and reuse |

| Speed Control | Adjustable rotation rates | Optimizes evaporation efficiency based on sample volume |

Elevate Your Lipid Extraction Precision with KINTEK

Don't compromise the chemical integrity of your botanical extracts. KINTEK’s high-performance rotary evaporators are engineered to provide the precise vacuum control and thermal stability required for the most sensitive crude lipid recoveries.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with a full range of lab high-temp furnaces—all customizable for your unique research or production needs.

Ready to optimize your lab's efficiency and yield? Contact us today to find your perfect solution!

Visual Guide

References

- Gyeongnam Park, Eilhann E. Kwon. Use of defatted cottonseed-derived biochar for biodiesel production: a closed-loop approach. DOI: 10.1007/s42773-024-00394-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the material and structural requirements for heating walls? Optimize Your Externally Heated Retorting Furnace

- Why is the ball milling step essential for NN-10ST ceramic synthesis? Unlock High-Purity Phase Formation

- Why is HR-TEM used after high-temperature heat treatment? Visualize structural evolution and material integrity.

- What are the advantages of using a vacuum drying oven for MnMgPO4@C3N4? Preserving Photocatalyst Integrity

- What is the function of a stable heating environment and ethylene glycol in gold nanoparticle synthesis? Achieve Precision

- What are the process advantages of using a powder mixture for siliconization? Ensure Uniformity on Complex Geometries

- How is an industrial heating furnace used for 20MnCr gear steel normalization? Master Microstructural Integrity

- Why is a stainless steel high-pressure autoclave essential for starch hydrogenation? Unlock Peak Reaction Efficiency