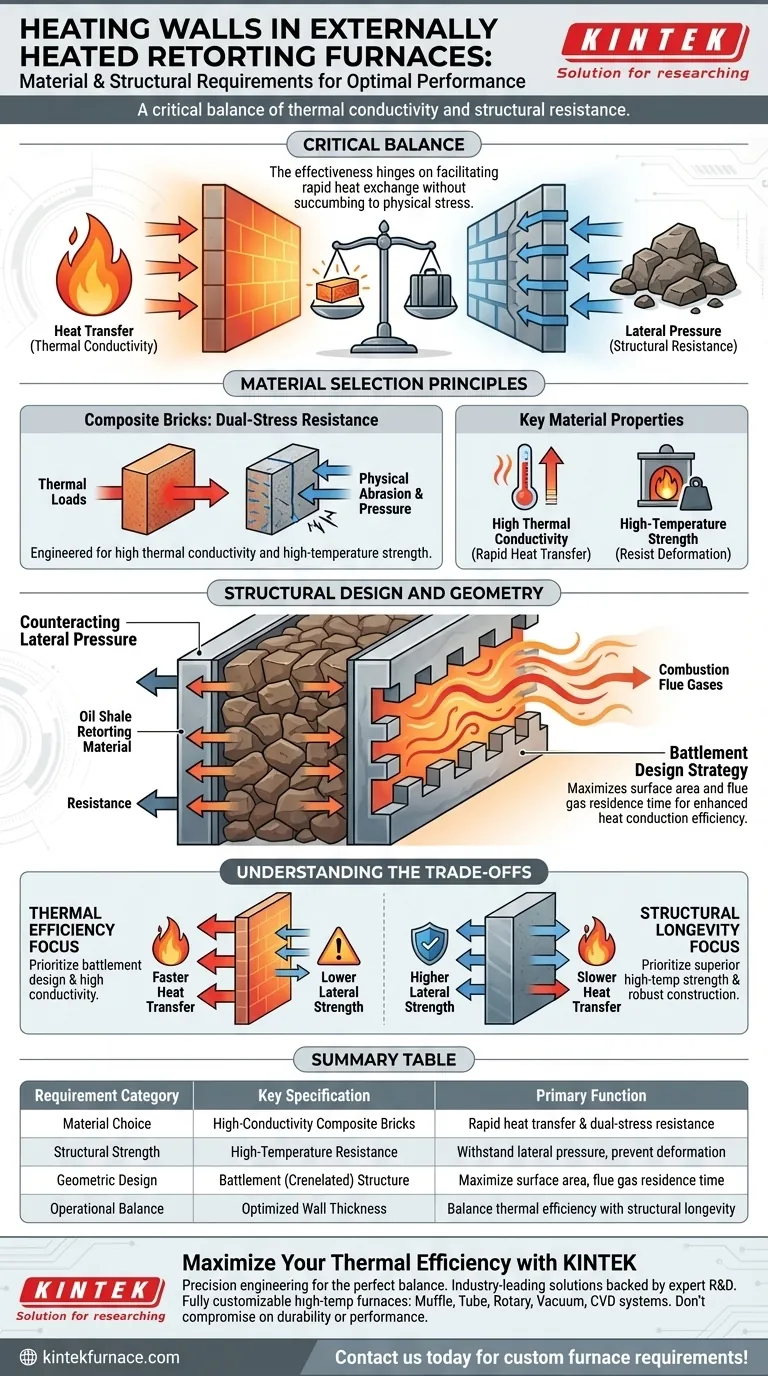

Heating walls in externally heated retorting furnaces are defined by a critical balance of thermal conductivity and structural resistance. Materially, these walls are typically constructed using composite bricks that offer high thermal conductivity to transfer heat efficiently while maintaining high-temperature strength. Structurally, they are designed to withstand significant lateral pressure from the internal retorting materials and often feature a battlement geometry to maximize contact with combustion flue gases.

The effectiveness of a retorting furnace hinges on the heating wall's ability to facilitate rapid heat exchange without succumbing to physical stress. The integration of conductive composite materials with a surface-maximizing battlement design ensures the oil shale receives sufficient reaction heat while the structure remains stable.

Material Selection Principles

The Necessity of Composite Materials

The primary material requirement for these heating walls is the use of specialized composite bricks. Unlike standard refractory bricks, these composites are engineered to handle dual stresses: thermal loads and physical abrasion.

Prioritizing Thermal Conductivity

High thermal conductivity is non-negotiable. The wall acts as the interface between the combustion heat and the raw material; therefore, the material must allow heat to pass through rapidly to ensure the oil shale reaches reaction temperatures efficiently.

High-Temperature Strength

The material must possess exceptional strength at elevated temperatures. Because the furnace operates under continuous high heat, the bricks must resist deformation or failure while supporting the furnace structure.

Structural Design and Geometry

Counteracting Lateral Pressure

Structurally, the walls must be robust enough to contain the physical load of the material being processed. In the retorting section, the oil shale exerts significant lateral (outward) pressure, which the wall must resist to prevent collapse or bulging.

The Battlement Design Strategy

To enhance efficiency, these walls often incorporate a battlement (crenelated) design. This geometric structuring is not merely aesthetic; it serves a specific functional purpose in thermodynamics.

Maximizing Heat Transfer

The battlement design significantly increases the surface area available for contact with combustion flue gas. By creating a more complex path, it prolongs the residence time of the gas against the wall, thereby strengthening heat conduction efficiency.

Understanding the Trade-offs

Thermal Efficiency vs. Structural Bulk

A common challenge in design is balancing the wall's thickness. While a thinner wall might transfer heat faster, it may struggle to withstand the lateral pressure of the shale.

Material Complexity

Using high-grade composite bricks improves performance but adds complexity to maintenance and construction. The specialized nature of the battlement design also requires precise installation to ensure uniform heat distribution and structural integrity.

Making the Right Choice for Your Goals

When specifying requirements for heating walls, your focus determines your design priority.

- If your primary focus is Thermal Efficiency: Prioritize the battlement design to maximize the residence time of flue gas and select composites with the highest possible thermal conductivity rating.

- If your primary focus is Structural Longevity: Ensure the composite bricks have superior high-temperature strength specifications to withstand long-term lateral pressure from the oil shale load.

Success lies in selecting a wall system that transfers heat aggressively without compromising its ability to contain the heavy material load.

Summary Table:

| Requirement Category | Key Specification | Primary Function |

|---|---|---|

| Material Choice | High-Conductivity Composite Bricks | Rapid heat transfer and dual-stress resistance |

| Structural Strength | High-Temperature Resistance | Withstanding lateral pressure and preventing deformation |

| Geometric Design | Battlement (Crenelated) Structure | Maximizing surface area and flue gas residence time |

| Operational Balance | Optimized Wall Thickness | Balancing thermal efficiency with structural longevity |

Maximize Your Thermal Efficiency with KINTEK

Achieving the perfect balance between structural integrity and rapid heat transfer requires precision engineering. KINTEK provides industry-leading solutions backed by expert R&D and manufacturing to meet your most demanding thermal processing needs.

Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temp furnaces are fully customizable to your unique material and structural requirements. Don't compromise on durability or performance—partner with KINTEK to optimize your laboratory or industrial operations.

Contact us today to discuss your custom furnace requirements!

Visual Guide

References

- Lixin Zhao, Luwei Pan. Numerical Study of the Combustion-Flow-Thermo-Pyrolysis Process in an Innovative Externally Heated Oil Shale Retort. DOI: 10.3390/sym17071055

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does 500°C annealing affect NiO-doped Ga2O3 thin films? Optimize Your High-Precision Thermal Treatment

- What role do high-temperature industrial furnaces play in the pretreatment of spodumene for lithium extraction?

- How does rapid water cooling equipment contribute to the stability of the foaming agent in aluminum foam precursors?

- Why is a constant flow of CO2 maintained during biochar pyrolysis? Unlock Precision Material Engineering

- Why are a blast drying oven and a freeze dryer both necessary for GO nanofibers? Essential Drying Synergy

- What factors should be considered when selecting a furnace based on processing requirements? Optimize Your Thermal Process with the Right Equipment

- Why is an industrial constant temperature oven required to cure thermal pads? Ensure Superior Polymer Cross-Linking

- What is the purpose of using an Argon (Ar 5.0) protective atmosphere? Ensure Oxidation-Free Cooling