To select the right furnace, you must first define your core processing requirements, which include the maximum operating temperature, the necessary atmospheric conditions (or lack thereof), the size and volume of the materials you will process, and the required heating and cooling speeds. These factors directly dictate whether you need a specialized atmosphere furnace, a high-purity vacuum furnace, or a more general-purpose model.

The decision is not about buying a piece of equipment; it's about precisely controlling an environment. Your choice ultimately hinges on one fundamental question: does your process need to take place in a controlled gaseous atmosphere, or does it require the absolute purity of a vacuum?

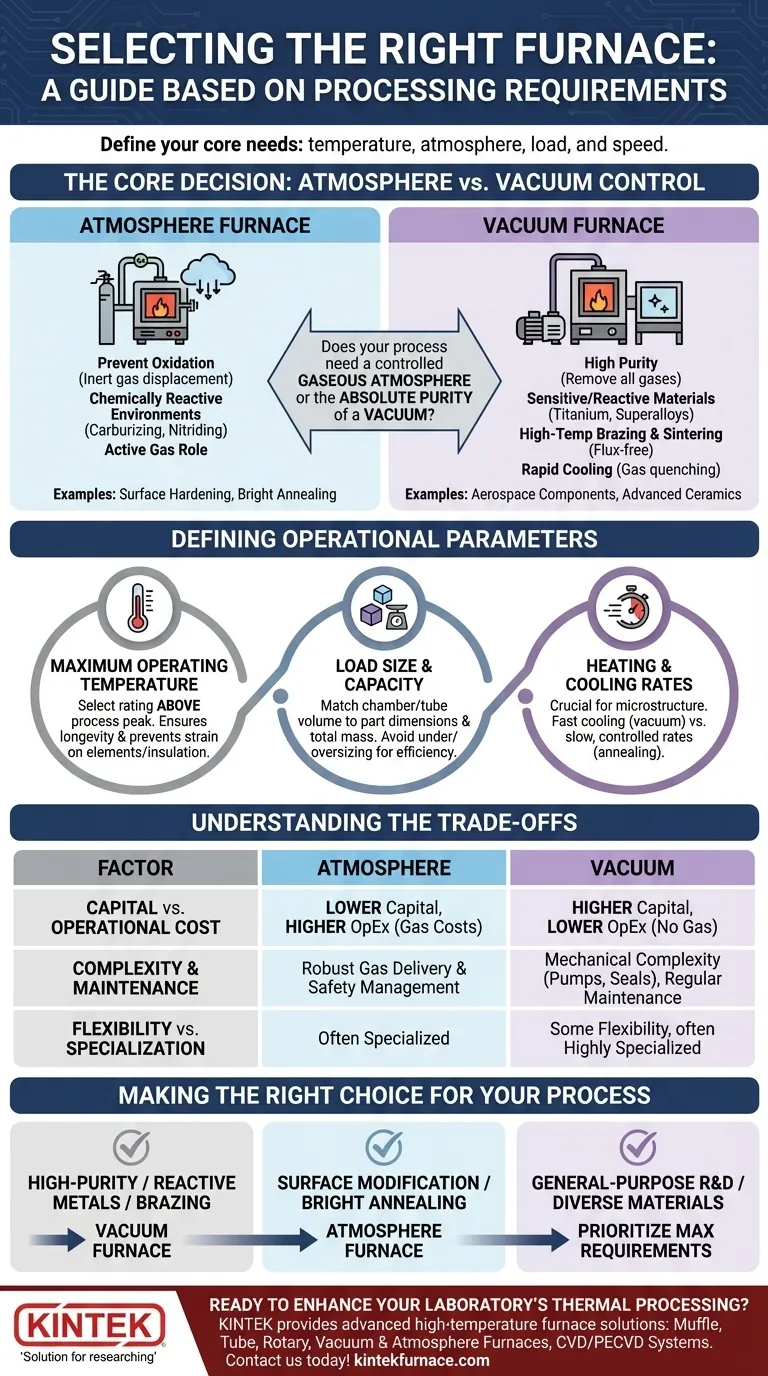

The Core Decision: Atmosphere vs. Vacuum Control

Your most critical decision is determining the environment your material needs during the thermal cycle. This choice has the largest impact on furnace design, cost, and process capability.

When to Choose an Atmosphere Furnace

An atmosphere furnace is designed to contain a specific gas or gas mixture at a controlled pressure and flow rate during processing. The gas is not simply present; it is an active part of the process.

These are essential when your goal is to prevent oxidation by displacing air with an inert gas like nitrogen or argon.

They are also used for processes that require a chemically reactive environment, such as carburizing (adding carbon) or nitriding (adding nitrogen) to harden the surface of steel parts.

When to Choose a Vacuum Furnace

A vacuum furnace is designed to remove the atmosphere—air and all other gases—from the processing chamber to an extremely low pressure. This creates a highly pure, non-reactive environment.

This is critical for processing highly sensitive or reactive materials like titanium or certain superalloys, which would be contaminated by even trace amounts of oxygen.

Vacuum environments are also ideal for high-temperature brazing and sintering, as the absence of atmosphere ensures clean joints and strong bonds without the need for flux, which can leave residue. The vacuum also facilitates outgassing, removing trapped contaminants from the part itself.

Finally, many vacuum furnaces offer rapid cooling (gas quenching) capabilities by backfilling the chamber with high-pressure inert gas, providing precise control over the material's final properties.

Defining Your Operational Parameters

Once you've decided between atmosphere and vacuum, you must specify the exact operational conditions. These details refine your selection and ensure the furnace can perform its task effectively and safely.

Maximum Operating Temperature

The required temperature is a hard limit. Always select a furnace with a maximum temperature rating that is comfortably above your highest process temperature.

This buffer ensures longevity and prevents straining the furnace's heating elements and insulation, which are designed for specific temperature ranges.

Load Size and Capacity

Consider the physical dimensions and total mass of the parts you will process in a single batch. This determines the required internal chamber volume or, for tube furnaces, the tube size specification.

Undersizing a furnace leads to low throughput, while significant oversizing is inefficient, wasting energy to heat an empty chamber.

Heating and Cooling Rates

The speed at which the furnace heats up and cools down can be just as important as the maximum temperature.

Some metallurgical processes require fast, controlled cooling to lock in a specific microstructure, a key advantage of many vacuum furnaces. Slower, more controlled rates may be needed for annealing or stress-relieving delicate components to prevent thermal shock.

Understanding the Trade-offs

Selecting a furnace involves balancing performance, cost, and complexity. Being aware of the inherent trade-offs is crucial for making a sound investment.

Capital Cost vs. Operational Cost

Vacuum furnaces typically have a higher upfront capital cost due to the need for high-integrity chambers, powerful pumping systems, and sophisticated controls.

Atmosphere furnaces may be less expensive to purchase but incur ongoing operational costs for the process gases (e.g., argon, nitrogen, hydrogen), which can be significant over the furnace's lifetime.

Complexity and Maintenance

A vacuum system introduces mechanical complexity with pumps, seals, and gauges that require regular maintenance to ensure performance and prevent leaks.

Atmosphere systems require robust gas delivery and safety management, especially when using combustible or hazardous gases like hydrogen.

Process Flexibility vs. Specialization

While some furnaces offer a degree of flexibility (such as a vacuum furnace that can run partial-pressure gas processes), a system designed for a specific task will almost always outperform a general-purpose one. If your needs are highly specific, customization can tailor a furnace to your exact requirements, but often at a premium.

Making the Right Choice for Your Process

Your process goals are the ultimate guide to your selection. Use these points to steer your final decision.

- If your primary focus is high-purity processing, brazing, or heat-treating reactive metals: A vacuum furnace is the correct and often only choice.

- If your primary focus is surface modification like carburizing, nitriding, or bright annealing: An atmosphere furnace provides the necessary reactive or inert gas environment.

- If your primary focus is general-purpose research or processing a wide variety of materials: Prioritize the highest temperature and most demanding atmosphere (or vacuum) requirement you anticipate to ensure future capability.

Ultimately, a detailed understanding of your material's needs empowers you to choose the furnace that will deliver consistent, reliable, and successful results.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Atmosphere vs. Vacuum | Choose atmosphere for reactive processes or oxidation prevention; vacuum for high-purity, sensitive materials, brazing, and sintering. |

| Maximum Temperature | Select a furnace with a rating above your highest process temperature to ensure longevity and avoid straining components. |

| Load Size and Capacity | Match chamber volume or tube size to part dimensions and mass for efficient throughput and energy use. |

| Heating and Cooling Rates | Consider required speeds for processes like fast cooling in vacuum furnaces or slow annealing to prevent thermal shock. |

| Cost and Complexity | Balance higher capital cost of vacuum furnaces vs. operational gas costs for atmosphere furnaces; factor in maintenance needs. |

Ready to enhance your laboratory's thermal processing capabilities? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need precise atmosphere control, high-purity vacuum environments, or tailored solutions for materials like reactive metals or steel, we can help you achieve consistent, reliable results. Contact us today to discuss your specific needs and discover how our furnaces can drive your research and production forward!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability