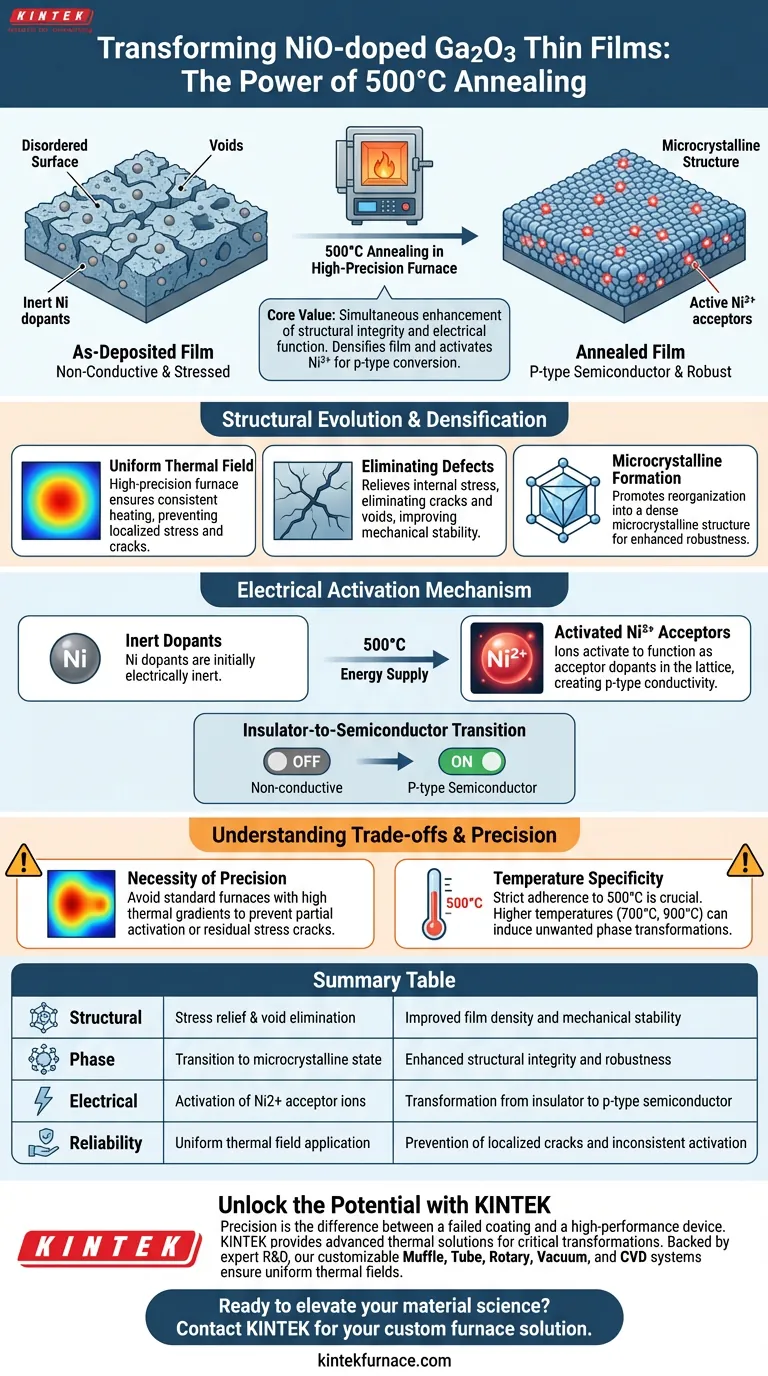

Annealing NiO-doped Ga2O3 thin films at 500°C triggers a critical transformation in both physical structure and electrical performance. This thermal treatment utilizes a high-precision furnace to repair deposition defects while simultaneously activating the material's semiconductor capabilities.

The core value of this process is the simultaneous enhancement of structural integrity and electrical function: it densifies the film by eliminating stress-induced voids and activates Ni2+ ions to convert a non-conductive layer into a functional p-type semiconductor.

Structural Evolution and Densification

The Role of Thermal Uniformity

Using a high-precision furnace is essential to establish a uniform thermal field.

Inconsistent heating can lead to localized stress points. A precise thermal environment ensures that the entire film undergoes the same physical changes simultaneously.

Eliminating Deposition Defects

Films often suffer from stress caused during the deposition phase.

The 500°C annealing process effectively relieves this internal stress. This results in the elimination of cracks and voids, significantly improving the mechanical stability of the layer.

Microcrystalline Formation

The thermal energy provided at this temperature promotes the organization of the material structure.

The film shifts toward a microcrystalline structure. This reorganization increases the overall film density, creating a more robust material compared to the as-deposited state.

Electrical Activation Mechanism

Activating the Dopant

Before annealing, the Nickel dopants may remain electrically inert.

The 500°C treatment supplies the energy required to activate Ni2+ ions. These ions begin to function as acceptor dopants within the crystal lattice.

The Insulator-to-Semiconductor Transition

The most significant functional change is the alteration of conductivity.

By activating the acceptors, the annealing process converts the initially non-conductive film into a high-performance p-type semiconductor. This is the critical step for enabling the material's use in electronic devices.

Understanding the Trade-offs

The Necessity of Precision

While the primary reference highlights the benefits, it implicitly underscores the need for equipment precision.

Standard furnaces with high thermal gradients may fail to produce the uniform field described. Without this uniformity, you risk partial activation or residual stress cracks in specific zones of the film.

Temperature Specificity

It is crucial to adhere strictly to the target temperature for this specific material system.

Supplementary data indicates that higher temperatures (e.g., 700°C or 900°C) can induce different phase transformations, such as converting materials to amorphous structures or altering bandgaps in iron-based oxides. For NiO-doped Ga2O3, 500°C is the calibrated point for achieving the desired microcrystalline p-type state.

Making the Right Choice for Your Goal

To maximize the utility of your NiO-doped Ga2O3 films, align your process controls with your specific end-goals:

- If your primary focus is Physical Durability: Ensure your furnace provides a strictly uniform thermal field to maximize density and eliminate void formation.

- If your primary focus is Electrical Conductivity: Verify that the 500°C dwell time is sufficient to fully activate the Ni2+ acceptors for p-type conversion.

Precision in thermal treatment is the bridge between a raw deposited coating and a high-performance semiconductor device.

Summary Table:

| Impact Category | Physical/Electrical Change | Resulting Benefit |

|---|---|---|

| Structural | Stress relief & void elimination | Improved film density and mechanical stability |

| Phase | Transition to microcrystalline state | Enhanced structural integrity and robustness |

| Electrical | Activation of Ni2+ acceptor ions | Transformation from insulator to p-type semiconductor |

| Reliability | Uniform thermal field application | Prevention of localized cracks and inconsistent activation |

Unlock the Potential of Your Semiconductor Materials

Precision is the difference between a failed coating and a high-performance electronic device. KINTEK provides the advanced thermal solutions necessary to achieve critical material transformations like the 500°C annealing of NiO-doped Ga2O3.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our high-temp lab furnaces are fully customizable to meet your unique research or production needs, ensuring the uniform thermal fields required for dopant activation and densification.

Ready to elevate your material science? Contact KINTEK today to find your custom furnace solution.

Visual Guide

References

- Cheng‐Fu Yang, Shu‐Han Liao. Analyses of the Properties of the NiO-Doped Ga2O3 Wide-Bandgap Semiconductor Thin Films. DOI: 10.3390/coatings14121615

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What is the significance of using high-temperature heating equipment to reach 1250°C for alloys? Stress Test Excellence

- What are the main types of heat treatment furnaces? Choose the Right Furnace for Your Lab or Industry

- What is the purpose of annealing the sapphire substrate at 980 °C with Cr? Achieve Unidirectional Cr2S3 Growth

- What are the advantages of mastering the sintering step? Achieve Cost Savings and Complex Designs

- What are the primary objectives of using a blast drying oven for In2O3/C nanofibers? Ensure Structural Integrity

- What is the primary function of a batch fixed bed reactor in the slow pyrolysis of teff husk? Maximize Biochar Yield

- Why is the use of silver-containing active brazing alloys prohibited in TEGs? Prevent Semiconductor Degradation

- Why is precise heating rate control necessary during the pyrolysis of bamboo? Optimize Au-NPs/BC Nanocomposite Quality