Mastering the sintering step is a cornerstone of modern powder metallurgy and advanced manufacturing. It is the critical process that allows for the creation of dense, strong, near-net-shape components directly from a powder base, which fundamentally changes the economics of production by drastically reducing or even eliminating the need for costly and wasteful machining operations.

The core value of mastering sintering is transforming a simple powder into a complex, high-performance component in a single thermal step. This unlocks opportunities for intricate designs, cost savings, and material properties that are often unachievable with traditional subtractive manufacturing methods.

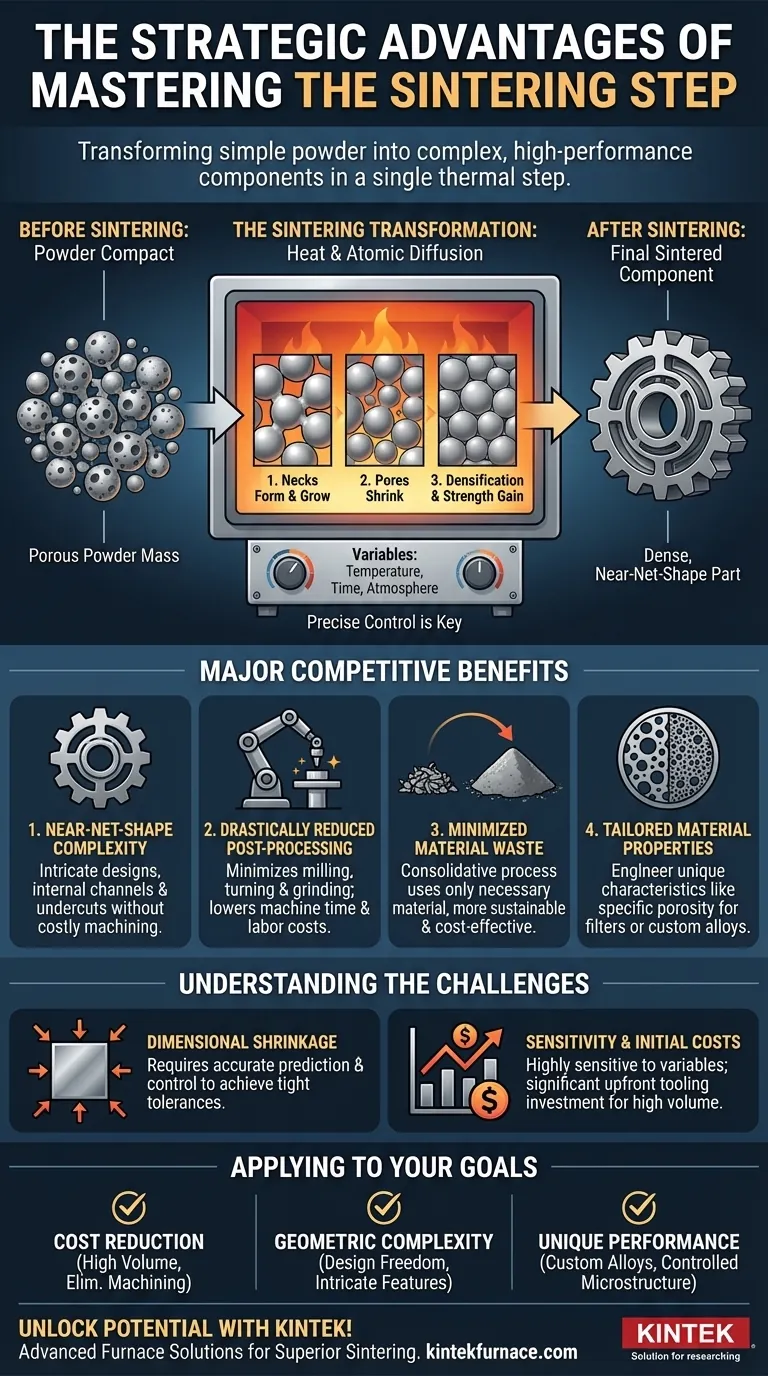

From Powder to Solid: The Sintering Transformation

To appreciate its advantages, you must first understand that sintering is not simply melting. It is a sophisticated process of atomic diffusion that occurs at temperatures below the material's melting point.

What is Sintering?

Sintering is a heat treatment applied to a compacted powder mass. The elevated temperature provides the energy for atoms to migrate across the boundaries of individual particles, fusing them together.

The Mechanism of Consolidation

This process happens in stages. First, "necks" form at the contact points between particles. As heating continues, these necks grow, and the pores between particles shrink, causing the entire part to densify and gain strength.

Why Control Is Everything

Mastering this process means precisely controlling the variables—temperature, time, and furnace atmosphere—to manage this atomic-level transformation. This control directly dictates the final part's density, dimensional accuracy, and mechanical properties.

The Strategic Advantages of Sintering Mastery

Controlling the sintering process translates directly into significant competitive and technical advantages that go far beyond a simple heating step.

1. Achieving Near-Net-Shape Complexity

The most significant advantage is producing parts that are extremely close to their final, or "net," shape. This allows for the creation of highly complex geometries, such as internal channels, undercuts, or intricate surface features, that would be difficult, prohibitively expensive, or impossible to create with machining.

2. Drastically Reducing Post-Processing Costs

Because parts emerge from the furnace already in their near-final shape, the need for subtractive processes like milling, turning, or grinding is minimized. This delivers a powerful economic benefit by reducing machine time, tooling wear, labor costs, and production bottlenecks.

3. Minimizing Material Waste

Traditional machining is a subtractive process; it starts with a large block of material and cuts away everything that isn't the final part, creating significant waste. Sintering is a consolidative process, using only the material needed for the part. This makes it a more sustainable and cost-effective method, especially with expensive or advanced materials.

4. Unlocking Tailored Material Properties

Mastery of sintering allows for the engineering of unique material characteristics. By controlling densification, you can intentionally create a specific level of porosity for applications like filters or self-lubricating bearings. It also enables the creation of metal matrix composites and unique alloys that cannot be formed through melting and casting.

Understanding the Trade-offs and Challenges

While powerful, the sintering process is not without its challenges. True mastery lies in understanding and mitigating these inherent complexities.

The Primary Challenge: Dimensional Shrinkage

As the powder particles fuse and the pores close, the component shrinks. This shrinkage can be non-uniform and is highly sensitive to powder characteristics and process parameters. Mastering sintering requires the ability to accurately predict and control this shrinkage to achieve tight dimensional tolerances.

Sensitivity to Process Variables

The final outcome is extremely sensitive to minor fluctuations in temperature, heating rate, hold time, and furnace atmosphere. A lack of precise control can lead to inconsistent density, poor mechanical properties, or dimensional inaccuracies, which is why expertise is so critical.

Initial Tooling and Equipment Costs

The dies and molds used to compact the powder before sintering can represent a significant upfront investment. This initial cost generally makes powder metallurgy and sintering most economical for medium-to-high-volume production runs where the tooling cost can be amortized over many parts.

Applying This to Your Manufacturing Goal

Your approach to sintering should be dictated by your primary objective.

- If your primary focus is cost reduction in high-volume production: Mastering sintering is essential for eliminating secondary machining operations and minimizing material waste, directly improving your per-part profitability.

- If your primary focus is geometric complexity and design freedom: Sintering allows you to manufacture parts with intricate features that are simply not feasible with traditional subtractive methods, unlocking new design possibilities.

- If your primary focus is creating materials with unique performance: The sintering process is a powerful tool for controlling microstructure, creating custom alloys, and engineering specific levels of porosity for specialized applications.

By treating sintering as a precise engineering control point rather than a bulk heating process, you unlock a superior method for manufacturing robust and complex components.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Near-Net-Shape Complexity | Enables intricate geometries without costly machining |

| Reduced Post-Processing Costs | Minimizes subtractive operations, saving time and money |

| Minimized Material Waste | Uses only necessary powder, ideal for expensive materials |

| Tailored Material Properties | Allows control of porosity and creation of unique alloys |

Unlock the full potential of sintering for your lab or production line with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, helping you achieve superior part density, dimensional accuracy, and cost efficiency. Contact us today to discuss how our tailored sintering solutions can drive your success in powder metallurgy and advanced manufacturing!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production