High-precision vacuum or atmospheric heat treatment furnaces act as the definitive tool for engineering the microstructure of Inconel 718. Their primary role is to execute the Solution Treatment and Aging (STA) process with exacting accuracy, maintaining specific temperature plateaus—most notably 980°C, 718°C, and 621°C—to transform the alloy’s internal structure. This process converts the detrimental Laves phase into the stable δ phase and drives the precipitation of the γ'' strengthening phase, which is essential for the material's mechanical performance.

Core Insight: The furnace is not merely a heating device; it is a precision instrument for phase management. By strictly controlling thermal cycles and atmospheric conditions, these furnaces dictate the morphology and volume of precipitates, directly bridging the gap between a raw component and one capable of enduring extreme tensile stress and creep.

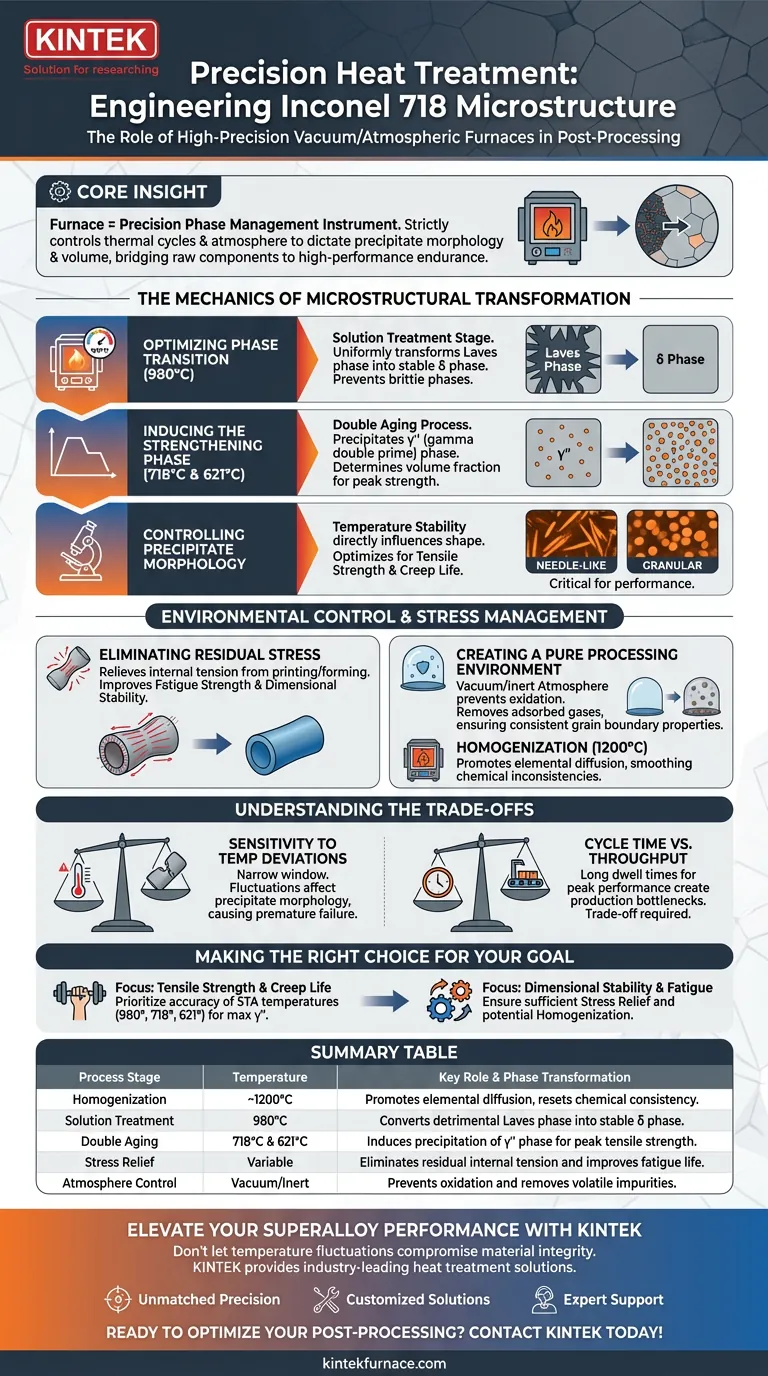

The Mechanics of Microstructural Transformation

Optimizing Phase Transition

The central function of these furnaces is to facilitate the transformation of the Laves phase into the δ phase.

This is achieved during the solution treatment stage, typically held at 980°C.

Precise thermal regulation ensures this transformation occurs uniformly, preventing brittle phases that would otherwise compromise the alloy's integrity.

Inducing the Strengthening Phase

Following solution treatment, the furnace executes a two-step aging process at 718°C and 621°C.

This multi-stage cycling induces the precipitation of the γ'' (gamma double prime) phase.

The accuracy of the furnace determines the volume fraction of these precipitates, which is the primary driver of Inconel 718’s high strength.

Controlling Precipitate Morphology

Temperature stability within the furnace directly influences the physical shape of the precipitates.

Variations in heat can shift precipitates between needle-like and granular morphologies.

Achieving the correct morphology is critical, as it optimizes the material's tensile strength and creep life (resistance to deformation under long-term stress).

Environmental Control and Stress Management

Eliminating Residual Stress

Beyond phase transformation, these furnaces play a vital role in mechanical stabilization.

During the printing or forming process, Inconel 718 accumulates significant internal tension.

High-precision heating cycles relieve this residual stress, significantly improving the component's fatigue strength and ensuring dimensional stability.

Creating a Pure Processing Environment

Industrial-grade vacuum or atmosphere furnaces provide a controlled environment that is free from contaminants.

By lowering the oxygen partial pressure (in vacuum systems), the furnace facilitates the removal of adsorbed gases and volatile impurities.

This prevents oxidation during high-temperature cycles, ensuring the grain boundaries remain pure and the material properties remain consistent.

Homogenization Capabilities

For components requiring a reset of their elemental distribution, these furnaces can reach higher temperatures, such as 1200°C.

This homogenization step promotes elemental diffusion, smoothing out chemical inconsistencies found in the raw material.

Understanding the Trade-offs

Sensitivity to Temperature Deviations

The primary risk in this process is the "narrow window" of operation.

If the furnace fluctuates even slightly from the required temperatures (e.g., drifting from 980°C), the morphology of the precipitates will change unpredictably.

This can result in a part that looks correct on the outside but fails prematurely under stress due to sub-optimal microstructure.

Cycle Time vs. Throughput

Implementing these multi-stage cycles (Homogenization, Solution, and Double Aging) is time-intensive.

Achieving maximum material performance requires long dwell times at specific temperatures.

This creates a bottleneck in production speed, forcing a trade-off between peak material properties and manufacturing throughput.

Making the Right Choice for Your Goal

When configuring your post-processing strategy for Inconel 718, consider your specific performance requirements:

- If your primary focus is Tensile Strength and Creep Life: Prioritize the accuracy of the Solution Treatment and Aging (STA) temperatures (980°C, 718°C, 621°C) to maximize γ'' precipitation.

- If your primary focus is Dimensional Stability and Fatigue Resistance: Ensure your cycle includes sufficient stress relief and potential homogenization to eliminate residual tensions from the manufacturing process.

Precision in heat treatment is the single most significant factor in converting Inconel 718 from a raw alloy into a high-performance superalloy.

Summary Table:

| Process Stage | Temperature | Key Role & Phase Transformation |

|---|---|---|

| Homogenization | ~1200°C | Promotes elemental diffusion and resets chemical consistency |

| Solution Treatment | 980°C | Converts detrimental Laves phase into stable δ phase |

| Double Aging | 718°C & 621°C | Induces precipitation of γ'' phase for peak tensile strength |

| Stress Relief | Variable | Eliminates residual internal tension and improves fatigue life |

| Atmosphere Control | Vacuum/Inert | Prevents oxidation and removes volatile impurities |

Elevate Your Superalloy Performance with KINTEK

Don't let temperature fluctuations compromise your material integrity. KINTEK provides industry-leading heat treatment solutions designed to meet the rigorous demands of Inconel 718 processing. Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique lab or industrial needs.

Our Value to You:

- Unmatched Precision: Maintain the narrow thermal windows required for optimal γ'' phase precipitation.

- Customized Solutions: Tailored furnace configurations for specific homogenization or STA cycles.

- Expert Support: Technical guidance to help you bridge the gap between raw components and high-performance alloys.

Ready to optimize your post-processing workflow? Contact KINTEK today to speak with our specialists about your high-temperature furnace requirements!

Visual Guide

References

- Koji Kakehi, Shohei Ishisako. Effects of base plate temperature on microstructure evolution and high-temperature mechanical properties of IN718 processed by laser powder bed fusion using simulation and experiment. DOI: 10.1007/s00170-024-13028-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature blast drying oven play in nanocomposite formation? Ensure Structural Stability

- Why is a vacuum freeze dryer used for Vivianite? Optimize Your LFP Synthesis with Superior Precursor Integrity

- What function does a laboratory drying oven serve in the processing of PZT precursor powders? Optimize Ceramic Quality

- What function does a water quenching tank serve in Ni-Ti alloy heat treatment? Lock in Superelasticity & Shape Memory

- What are the applications of sintering furnaces in 3D printing? Unlock High-Strength Parts for Aerospace and More

- What is the significance of the two-step carbonization process for EN-LCNF? Unlock High-Performance Energy Storage

- How is an industrial heating furnace used for 20MnCr gear steel normalization? Master Microstructural Integrity

- What is the function of a high-precision electric oven in ZnO-CuO synthesis? Expert Thermal Control for Nanosheets